Fabricated prefabricated wall panel, floor slab and connecting structure of fabricated prefabricated wall panel and floor slab

A technology of prefabricated wall panels and connecting structures, applied to floors, walls, building components, etc., which can solve the problems of complicated assembly steps, manpower impact, construction efficiency, and high manufacturing costs, and achieve convenient and fast assembly, improve the overall load-bearing effect, and reduce self-respecting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

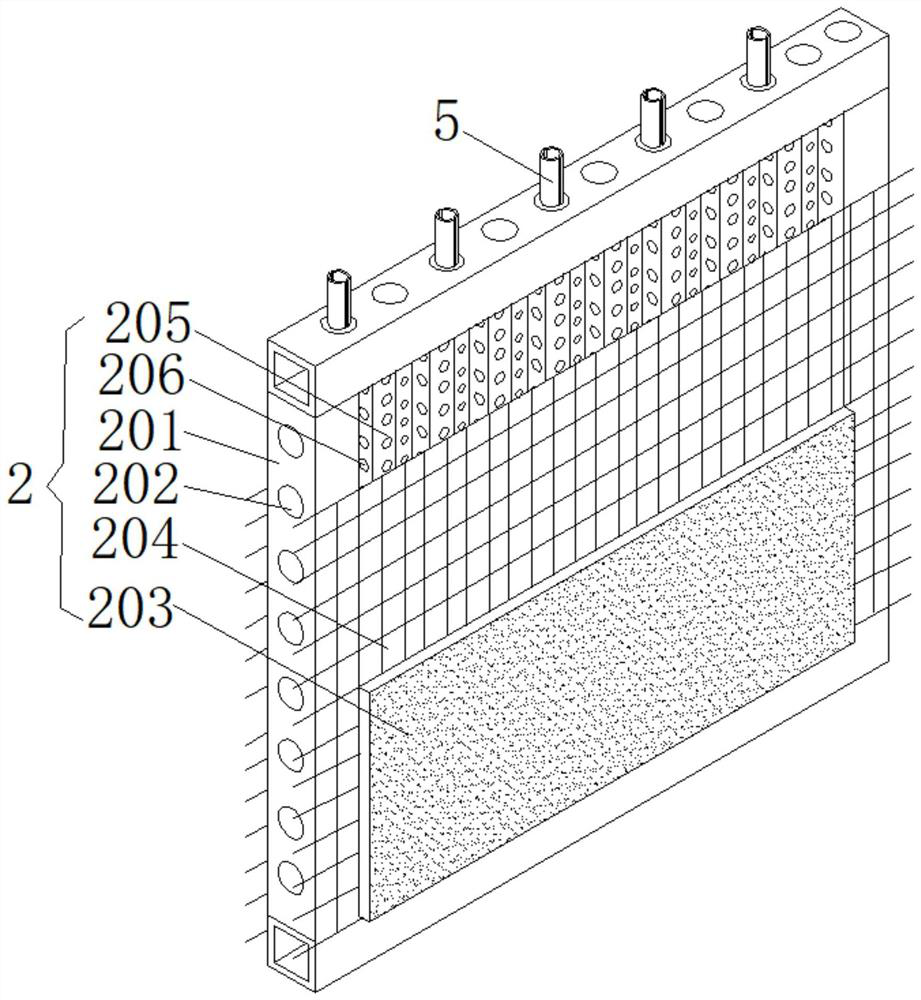

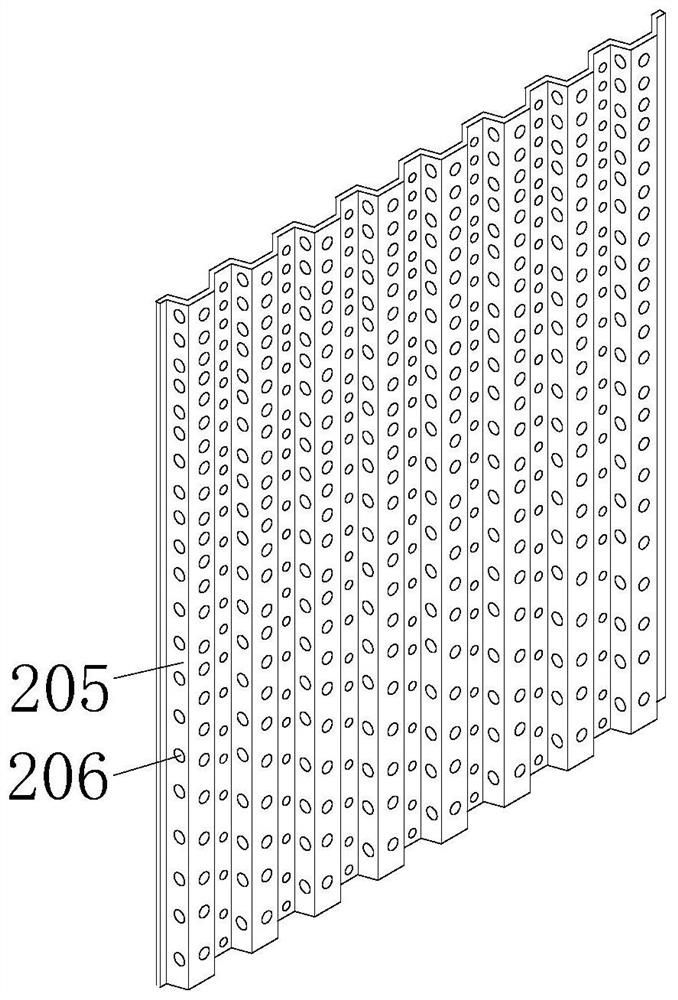

[0049] Such as Figure 7 Shown is a prefabricated prefabricated wall panel and floor slab connection structure suitable for low-rise buildings, the floor 1 is horizontally assembled between two wall panels 2, and the outer sides of the floor 1 and wall panels 2 are fixedly installed with connecting pieces 6, The connecting piece 6 is provided with a self-tapping screw 601, and the connecting piece 6 fixes the floor 1 and the wall panel 2 through the set self-tapping screw 601. The connection between the floor 1 and the wall panel 2 through the connecting piece 6 is especially suitable for rural low The construction of the building can be easily and quickly installed.

Embodiment 2

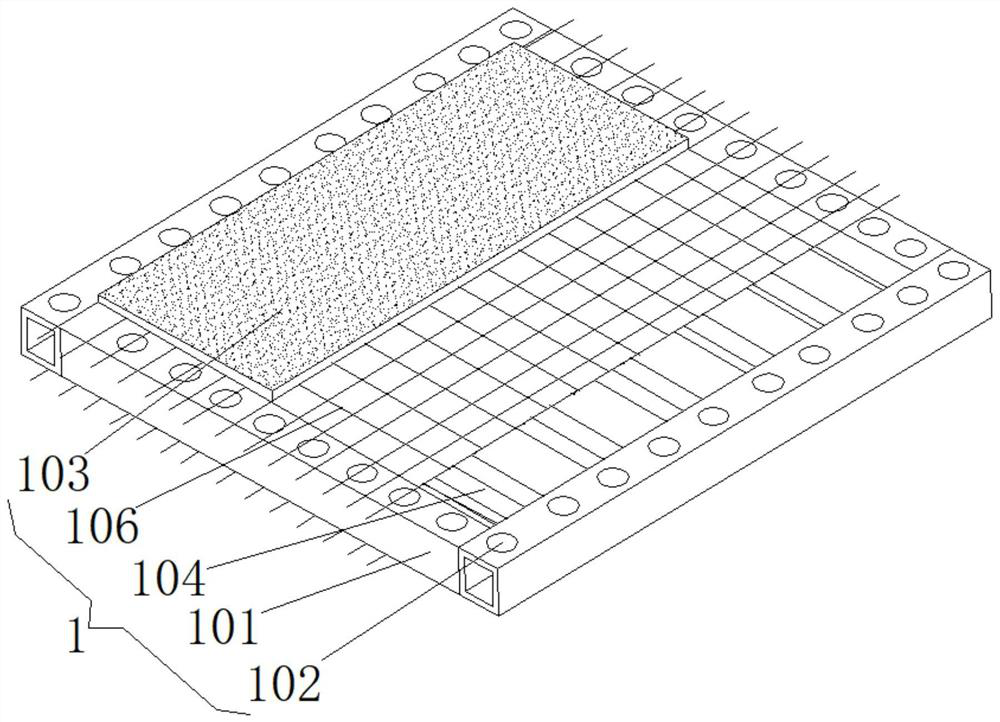

[0051] Such as Figure 8-10 Shown is a connection structure suitable for prefabricated prefabricated wall panels and floor slabs in low-rise buildings. The interior of the light steel frame-101 provided on the floor 1 is fixedly connected with a fixed plate 4, and the upper and lower surfaces of the fixed plate 4 are fixedly connected with Connecting rod 401, the upper and lower sides of the connecting rod 401 not in contact with the fixed plate 4 are fixedly connected with clamping balls 402, the clamping balls 402 are all provided with telescopic holes 404, and the insides of the telescopic holes 404 are fixedly connected with springs 405, 405 One end that is not in contact with the telescopic hole 404 is fixedly connected with a locking rod 403 .

[0052] The inside of the second through hole 202 provided by the wallboard 2 is fixedly connected with two fixing rings 5, the two fixing rings 5 are semi-circular, and the opposite sides of the two fixing rings 5 are provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com