Device and method for testing shield tunnel excavation face stability under gushing condition

A technology of stability test and shield tunnel, which is applied in soil material testing, material inspection products, etc., can solve the problem of unsystematic research on the stability of shield excavation surface, achieve significant scientific research value and engineering value, enrich soil and water effect of load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

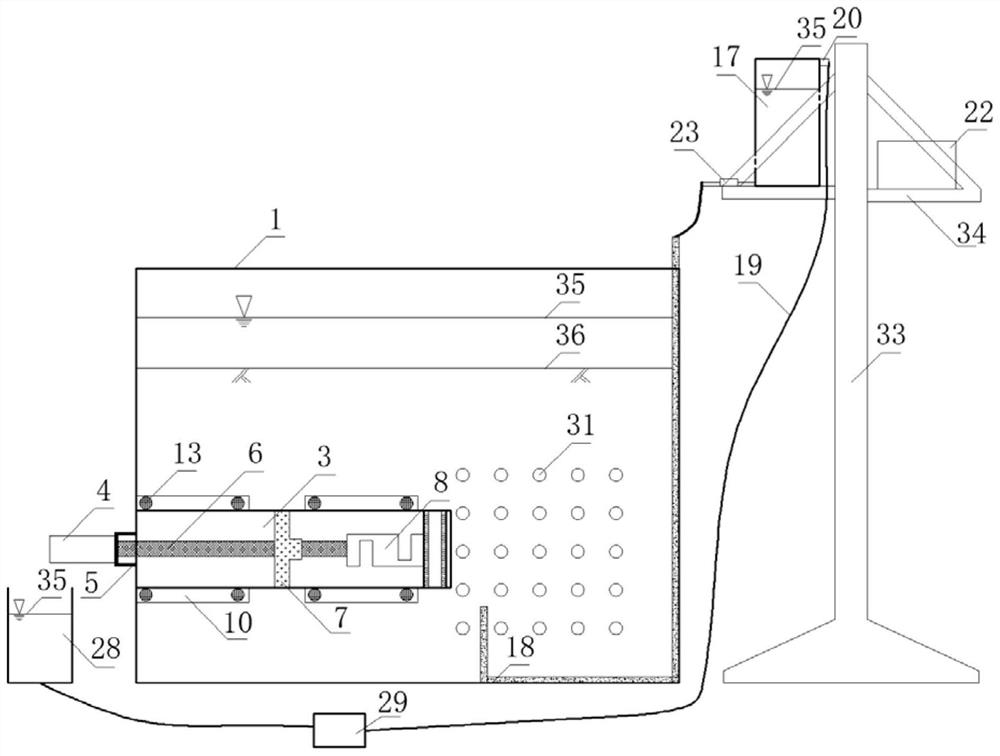

[0043] Such as figure 1 As shown, the shield tunnel excavation surface stability test device under spring conditions according to the present invention includes a model box 1, a tunnel excavation surface module, a water circulation module and a data acquisition module.

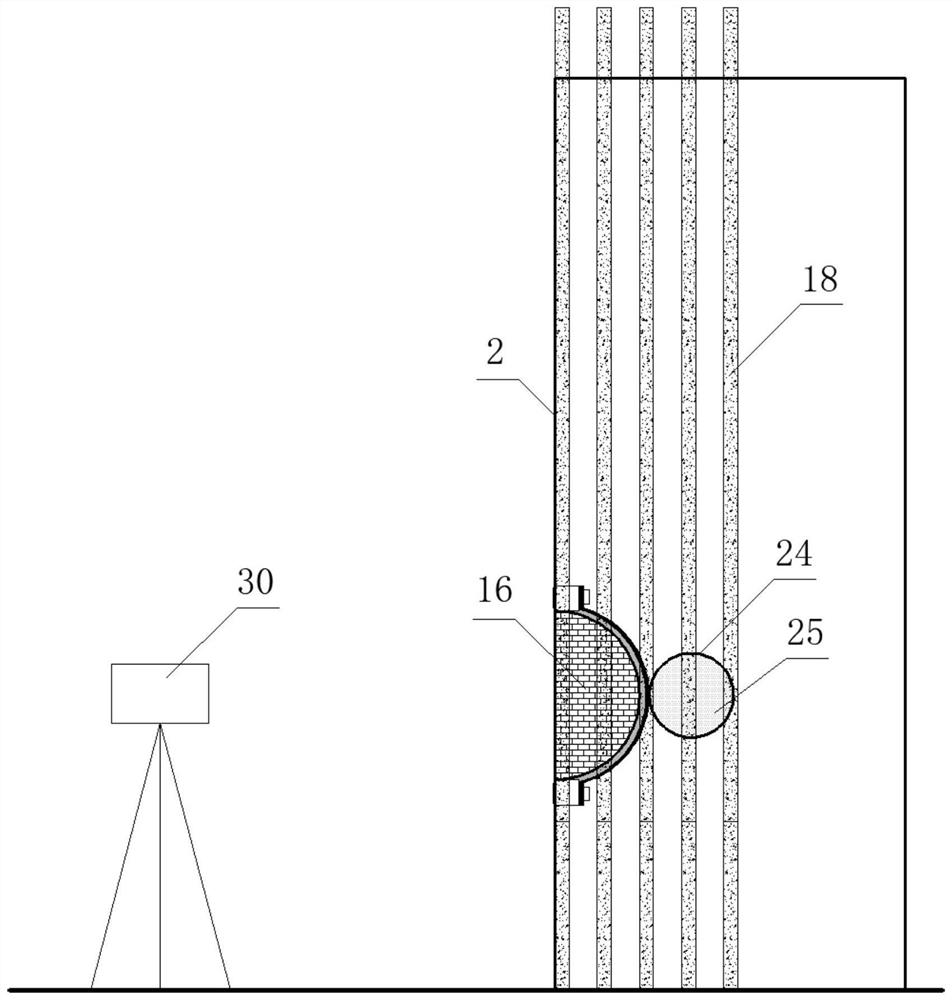

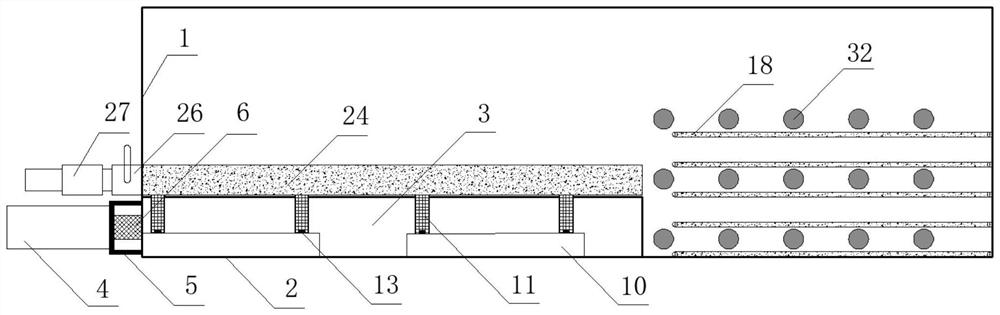

[0044] Such as figure 2 , image 3 As shown, the model box 1 is a cube, and the tunnel model 3 is connected to the measuring panel by bolts 13. The observation panel of the model box 1 is a toughened glass plate 2 with a thickness not less than 6 mm, and the side walls and bottom plates are all stainless steel with a thickness not less than 10 mm. plate.

[0045] The tunnel excavation surface module includes a tunnel model 3 , a servo motor 4 , a steel support 5 , a transmission rod 6 , a linear bearing 7 , a tension and pressure sensor 8 and an excavation panel 9 . The tunnel model 3 is a stainless steel semicircle-arc steel pipe, the wall thickness of the stainless steel semicircle-arc steel pipe is 12mm...

Embodiment 2

[0049] Such as Figure 8 As shown, the shield tunnel excavation face stability test method under the gushing condition of the present invention comprises the following steps:

[0050] (1) Clean up the site: fix the device on a clean and level site, install and clean the test device according to the fixed position, paste a layer of film on the bottom plate of the model box 1, and fix the permeable stone 25 on the inner side of the drainage steel pipe 24 model box 1 , the water inlet hole and the drain hole are all covered with one layer of filter paper, and the control water tank 17 and the spring control cabinet 22 are placed on the bearing platform 34 of the lifting frame 33 .

[0051] (2) Placement of sensors: according to the requirements of the test plan, the pore pressure sensor 32 and the earth pressure box 31 are placed at the corresponding positions of the research point, and the wires of the tension and pressure sensor 8, the pore pressure sensor 32 and the earth pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com