Lamination device and lamination method

A lamination device and lamination technology, applied in the direction of battery assembly, sustainable manufacturing/processing, climate sustainability, etc., can solve the problems of low lamination efficiency, achieve fast folding, and improve the effect of lamination efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

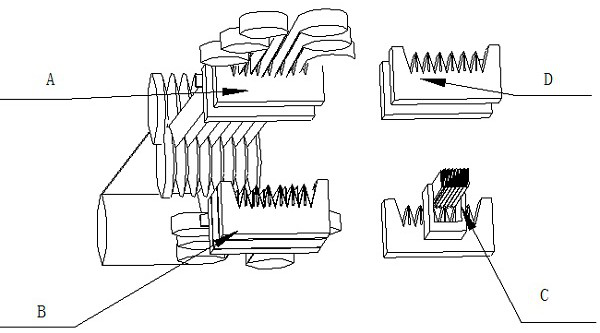

[0076] The lamination device provided in Example 2 can form a sawtooth-shaped diaphragm through the setting of the roll forming mechanism, and then clamp in the width direction through the clamping mechanism, and the finished battery unit can be formed by pressing and clamping only once; In the prior art, it is necessary to fold and press multiple times along the length direction of the separator to form the finished battery unit, which greatly improves the lamination efficiency.

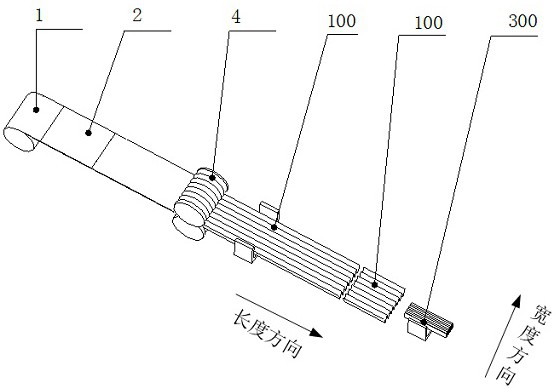

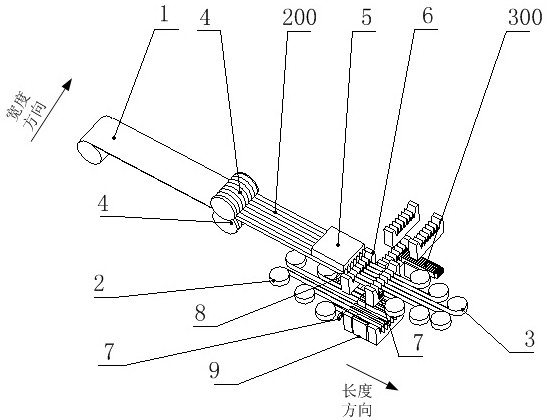

[0077] On the other hand, if figure 1 As shown, Embodiment 3 of the present invention also provides a lamination method, which is realized by using the lamination device of Embodiment 1, including steps:

[0078] The diaphragm unwinding mechanism releases the diaphragm 1;

[0079] The positive electrode sheet conveying mechanism outputs the positive electrode sheet 2, and the negative electrode sheet conveying mechanism outputs the negative electrode sheet 3, and the positive electrode sheet 2 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com