Anti-impact and wear-resistant electric heater

An electric heater, wear-resistant technology, applied in the direction of ohmic resistance heating parts, etc., can solve the problems of inability to adjust the electric heater, inconvenient use of containers of different sizes, and affect the heating effect, etc., to achieve safe and efficient operation and practicality strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

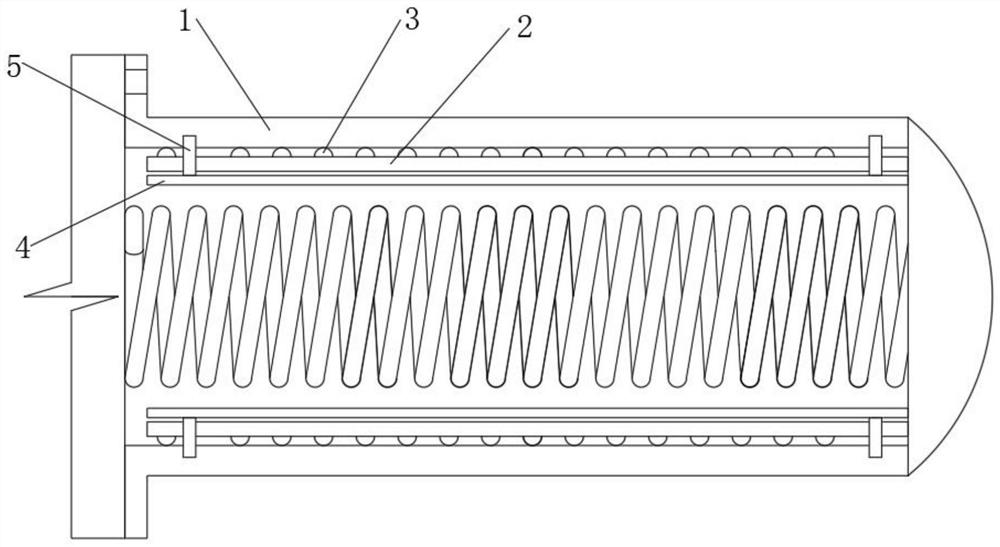

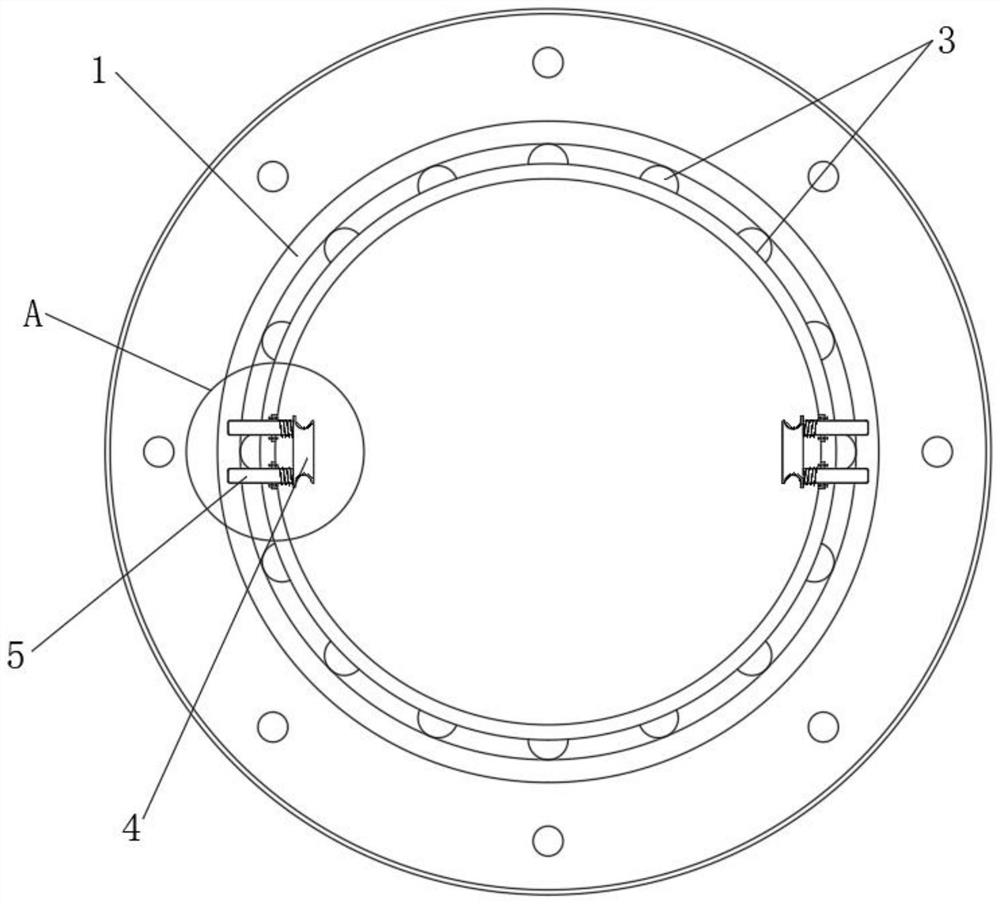

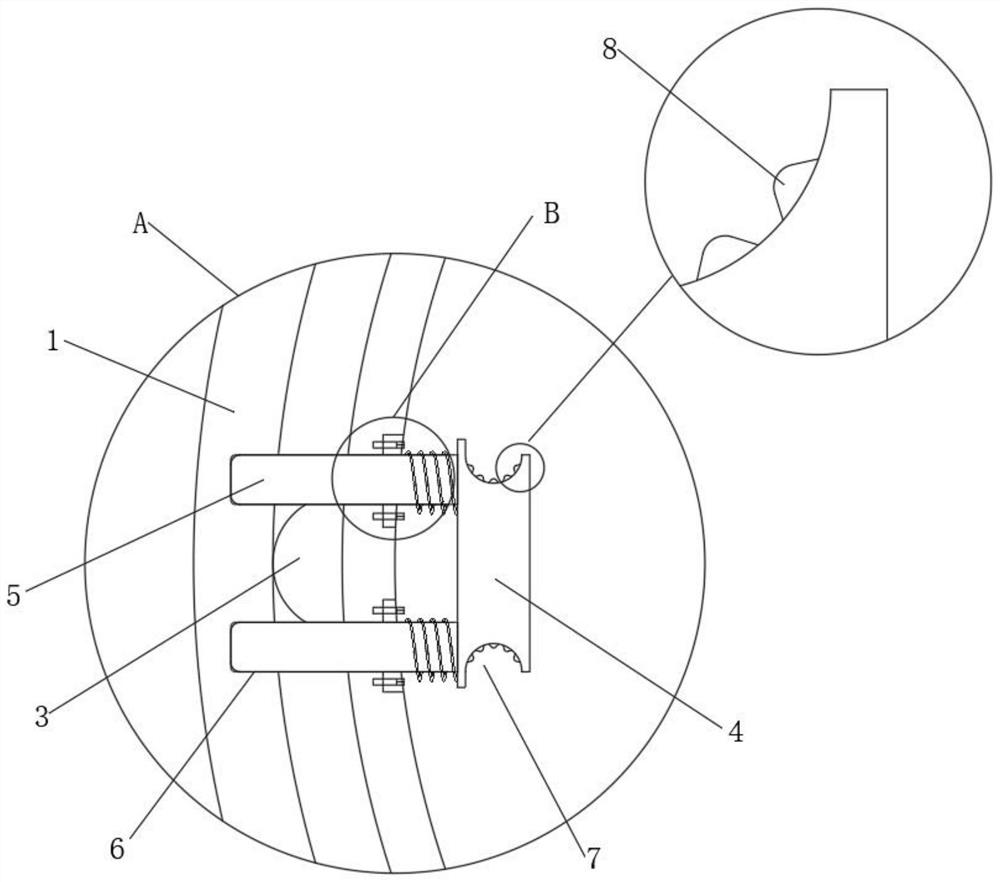

[0020] see Figure 1-4 , the present invention provides the following technical solutions: an anti-shock and wear-resistant electric heater, including an outer cylinder 1, an inner cylinder 2 and a bump 3, the outer cylinder 1 is sleeved outside the inner cylinder 2, and the outer wall of the inner cylinder 2 A plurality of bumps 3 are distributed, and an installation assembly is provided on the inner side of the inner cylinder 2. The installation assembly includes an installation plate 4 and a positioning post 5. There are two installation plates 4 in total, and the two installation plates 4 are located within the center of the inner cylinder 2. The positions are distributed symmetrically. One side of a single mounting plate 4 is connected with four positioning posts 5, and the four positioning posts 5 are arranged at four corners of a rectangle. Positioning cards are provided at positions corresponding to the positioning posts 5 in the outer cylinder 1. Groove 6, the install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com