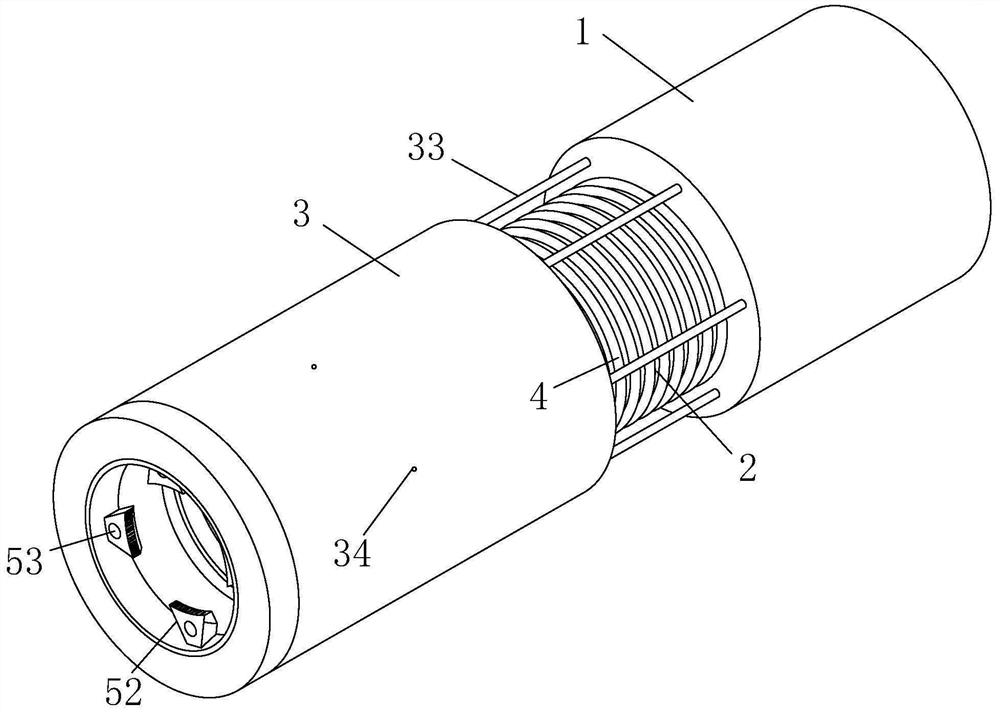

Pneumatic hot riveter head

A technology of pneumatic heat and riveting guns, applied in the field of heat riveting gun heads, can solve problems such as the deflection of the rivet rod and affect the effect, and achieve the effect of reducing the inclination, reducing the residue, and improving the appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

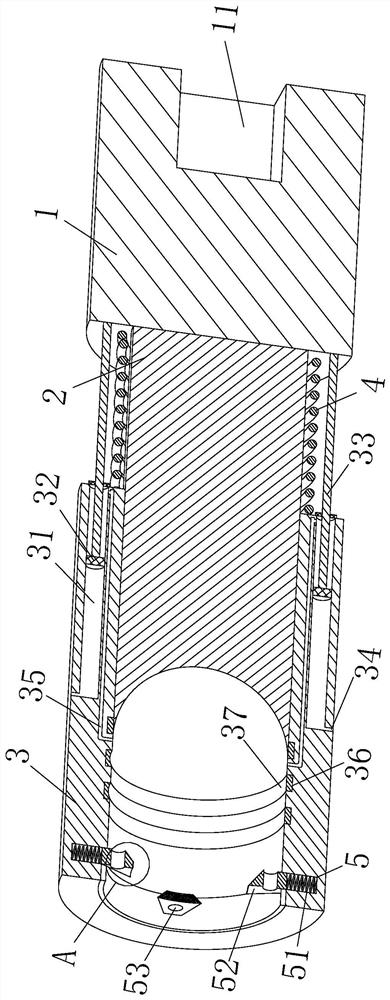

[0029] As an embodiment of the present invention, the inside of the guide sleeve 3 is provided with an evenly arranged annular groove 37; inside the annular groove 37, a reinforcing ring 36 is fixedly connected; Diameter corresponds to matching design;

[0030] During work, the cornbread 2 is a consumable item, and it is subjected to force impact for a long time. Since the edge position of the depression on the left end surface of the cornbread 2 is relatively weak, the cornbread 2 and the rivet rod are easily damaged during the impact process, and the inside of the guide sleeve 3 The space is provided with evenly arranged annular grooves 37, and the interior of the annular grooves 37 is fixedly connected with a reinforcing ring 36. The internal diameter of the reinforcing ring 36 is designed to match the internal diameter of the cornbread 2, so that the reinforcing ring 36 of the steamed cornbread 2 can be placed in the stress process. The weak parts of the cornbread 2 are pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com