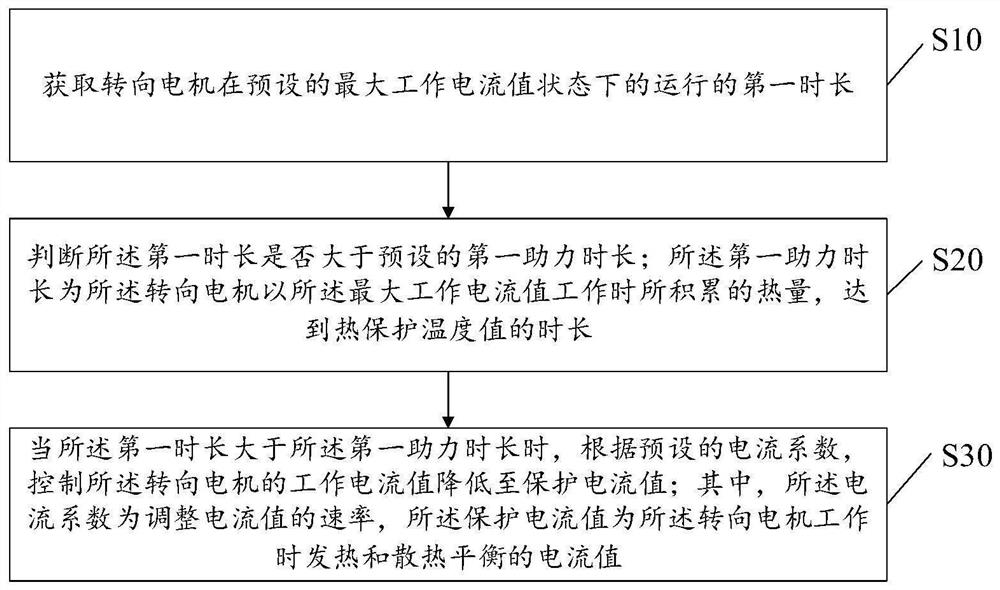

Thermal protection control method and device for steering motor

A technology of steering motor and control method, applied in the direction of motor control, control system, electrical components, etc., can solve the problems of short service life of steering motor, unstable service life of steering motor, easy failure of steering motor, etc., so as to prolong the service life. , to ensure the effect of work stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

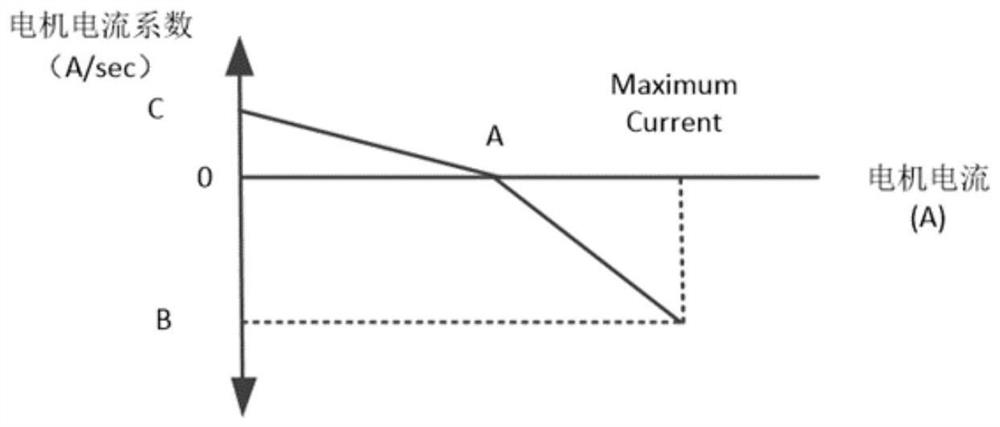

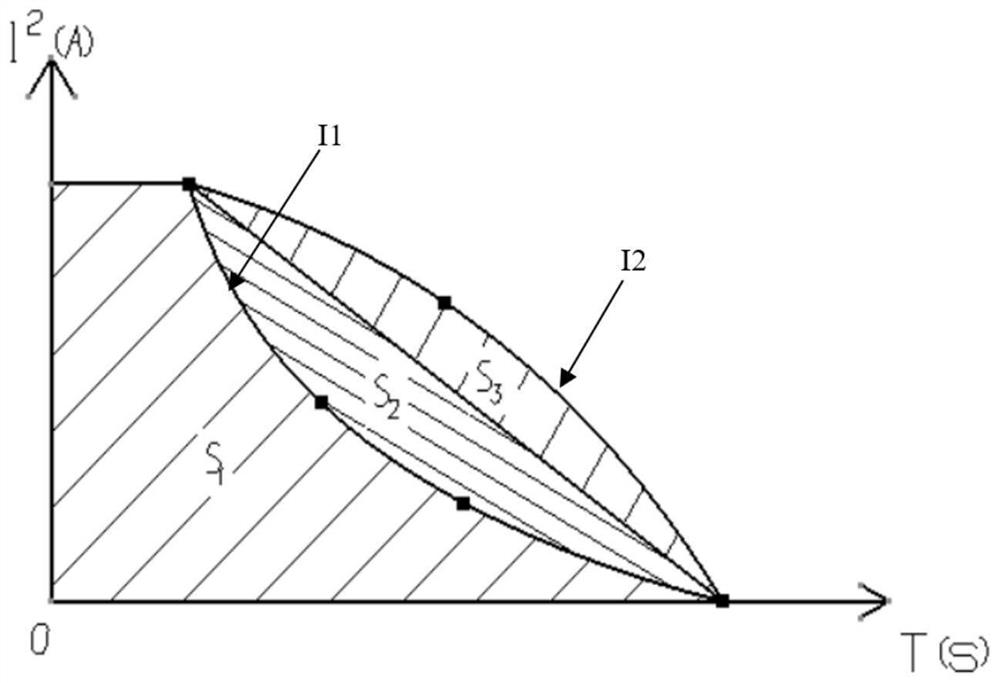

[0052] When the thermal protection temperature value is the maximum temperature value, it is monitored that when the first time of working at the maximum operating current value reaches t2, the temperature reaches 125°C, and the operating current can be reduced to the protection current value B1, so that the steering motor reaches a thermal balance state . At this time, the current change curve is C1.

example 2

[0054] When the thermal protection temperature value is less than the maximum temperature value, the setting value turns to the working platform of the motor at the middle current value. First, when it is detected that the temperature reaches 100° C. when the first duration of working at the maximum operating current value reaches t1 , the operating current can be reduced to the middle current B2 . When working in the middle current value B2 state, the heat accumulation of the steering motor is slow, which can further increase the working time to reach the maximum temperature value. Then, when the second duration (T2-T1) reaches the preset second assist duration and the temperature reaches 125°C, the working current value of the control steering motor is reduced to the protection current value B1 according to the current coefficient to reach a thermal equilibrium state. At this time, the current change curve is C2.

[0055] Compared with Example 1, the adjustment method in Ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com