A processing method and system for preparing metal single-element two-dimensional topological materials

A two-dimensional topology and processing method technology, applied in the field of processing methods and systems for preparing metal single-element two-dimensional topological materials, can solve the problems of harsh processing conditions and processing equipment, inconvenient wide implementation and application, and avoid toxic chemical reagents The use of high-cost and high-precision equipment is avoided, and the effect of good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

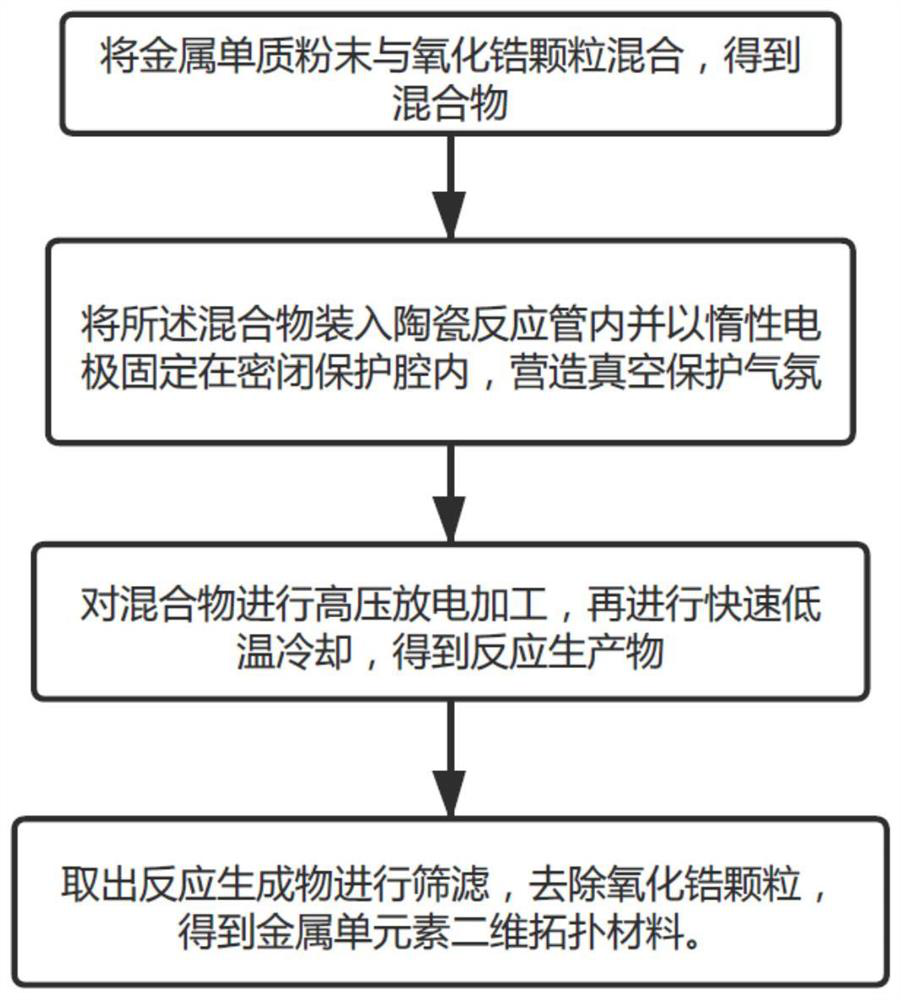

[0032] like figure 1 As shown, a processing method for preparing metal single-element two-dimensional topological materials, which includes the following content:

[0033] The elemental metal powder is mixed with zirconia particles to obtain a mixture.

[0034] The mixture is packed into a ceramic reaction tube and fixed in a closed protection chamber with an inert electrode to create a vacuum protection atmosphere.

[0035] The mixture is subjected to high-voltage electric discharge machining, and then subjected to rapid low-temperature cooling to obtain a reaction product.

[0036] The reaction product was taken out and sieved to remove zirconia particles to obtain a metal single-element two-dimensional topological material.

Embodiment 2

[0038] A method for preparing a metal single-element two-dimensional topological material, comprising the following steps:

[0039] S1. Prepare a mixture of germanium powder and zirconia particles: sieve zirconia particles with a particle size of 2-3mm and fully mix them with germanium metal powder;

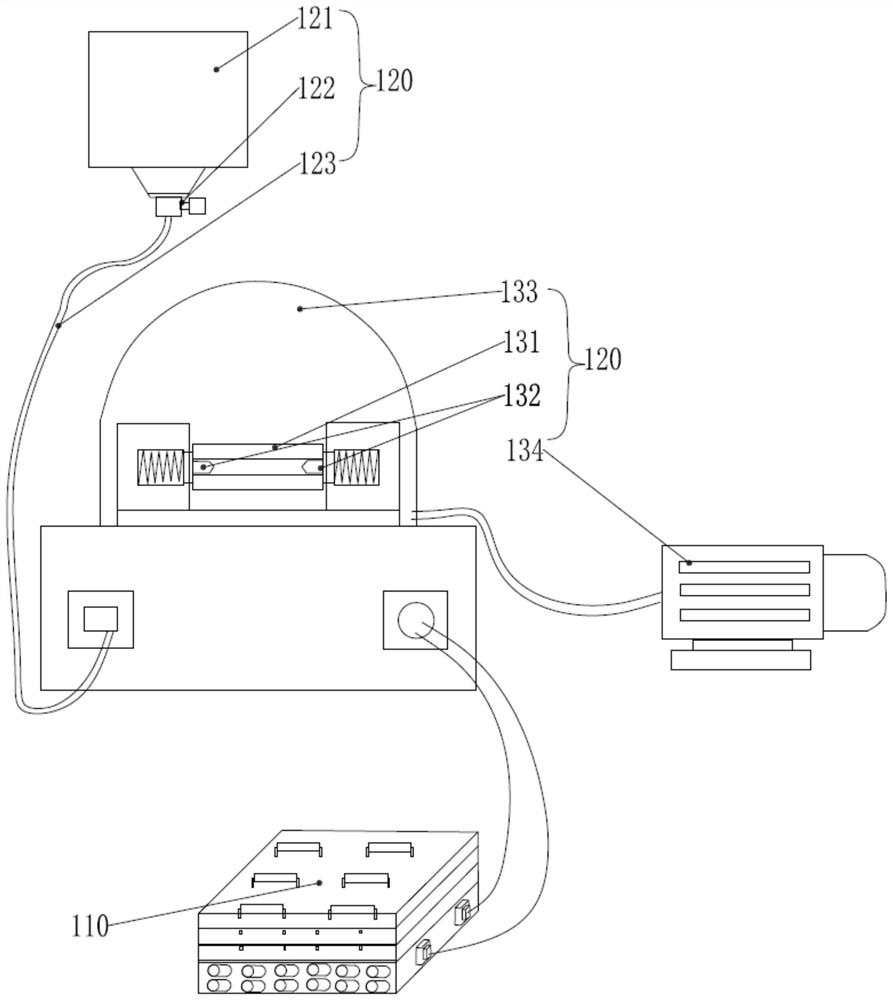

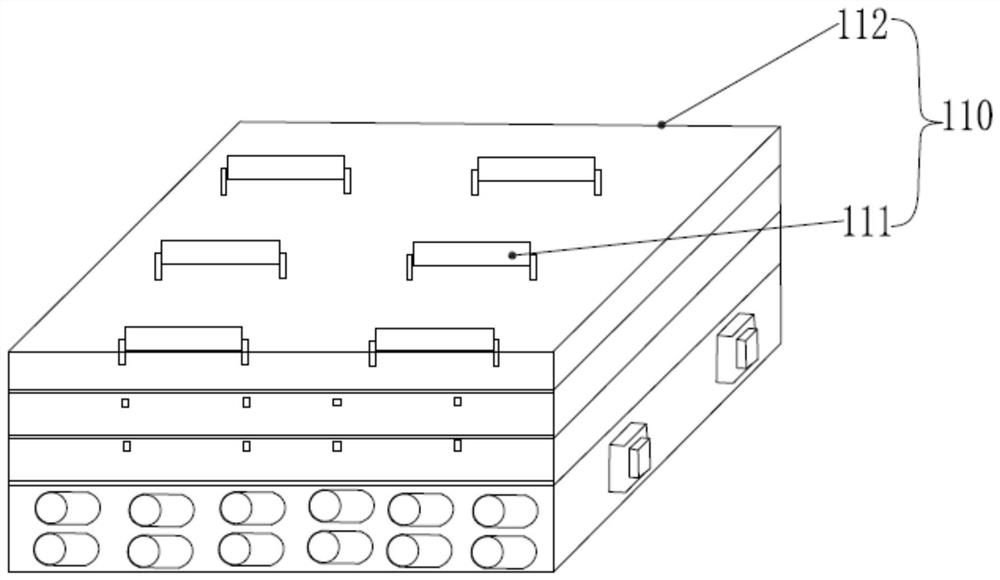

[0040] S2. Fill the mixture prepared in S1 into the ceramic reaction tube, and press it properly so that the mixture can be fully contacted together, while leaving a certain margin to reserve space for subsequent high-temperature processing expansion; The graphite electrode slot of the spring fixes the ceramic reaction tube; both ends of the electrode are in full contact with the mixture to form a certain clamping force; use a vacuum pump to vacuumize the sealed protection chamber, and the vacuum degree is 5Pa;

[0041] S3. The mixture is subjected to discharge machining by a transient high-voltage discharge system, and subjected to rapid low-temperature cooling, which specifical...

Embodiment 3

[0047] A method for preparing a metal single-element two-dimensional topological material, comprising the following steps:

[0048] S1. Prepare a mixture of tin powder and zirconia particles: sieve zirconia particles with a particle size of 2-3mm and fully mix them with germanium metal powder;

[0049] S2. Fill the mixture prepared in S1 into the ceramic reaction tube, and press it properly so that the mixture can be fully contacted together, while leaving a certain margin to reserve space for subsequent high-temperature processing expansion; The graphite electrode slot of the spring fixes the ceramic reaction tube; both ends of the electrode are in full contact with the mixture to form a certain clamping force; use a vacuum pump to vacuumize the sealed protection chamber, and the vacuum degree is 5Pa;

[0050] S3. The mixture is subjected to discharge machining by a transient high-voltage discharge system, and subjected to rapid low-temperature cooling, which specifically inc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com