Segmented bending soft finger based on variable rigidity and local thin wall and manufacturing method of segmented bending soft finger

A variable stiffness, thin-walled technology, applied in the field of segmented bending soft fingers and their production, can solve the problems of segmental bending that cannot be bent by soft fingers, and that the stiffness of soft fingers is low and cannot be grasped, etc., and achieve segmental bending effect. Significantly, the overall stiffness of the fingers increases, and the effect of lifting heavy objects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

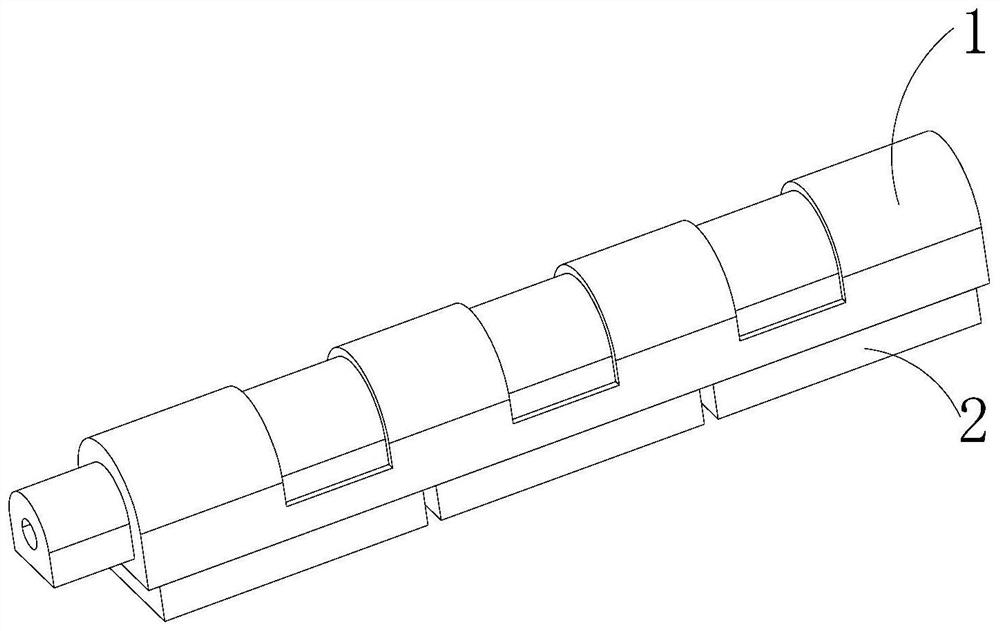

[0038] Please refer to figure 1 and 2 , the embodiment of the present invention provides a segmented bending soft finger based on variable stiffness and local thin-wall, including a finger cavity 1 and a plurality of variable stiffness layers 2 .

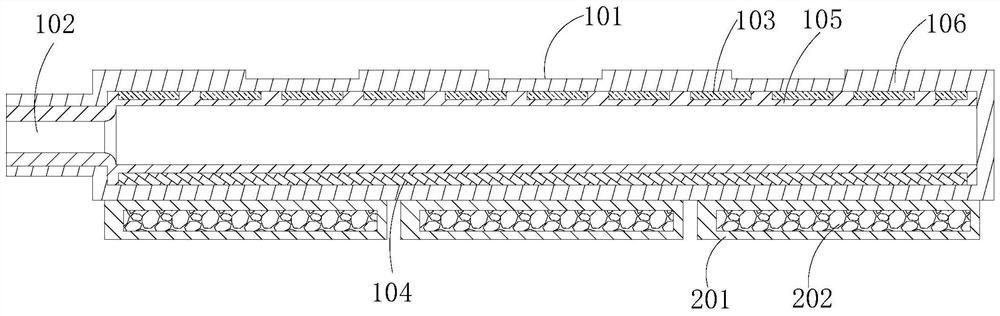

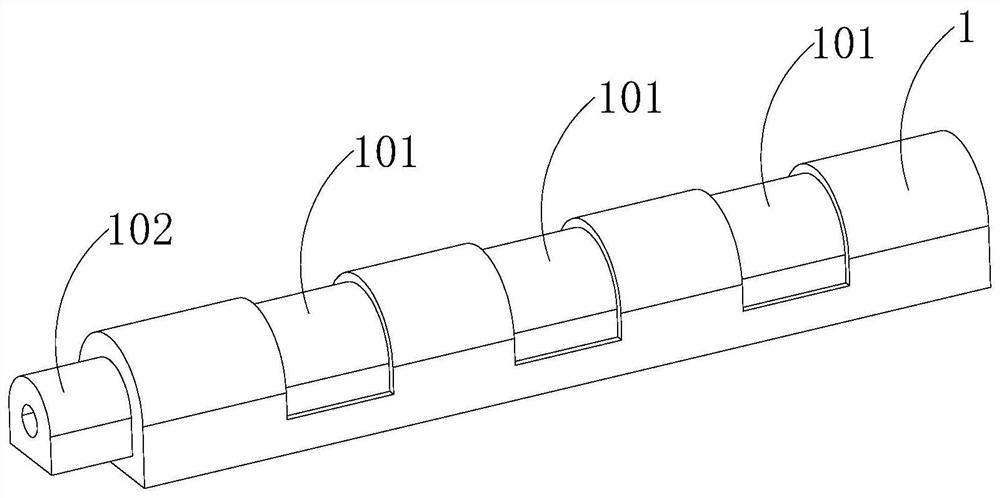

[0039] Among them, please refer to image 3 , the finger cavity 1 is a columnar structure, and its cross-sectional shape is preferably U-shaped, which is closer to the shape of a real finger. The interior of the finger cavity 1 is a sealed cavity, and one end of the cavity is provided with an inflation port 102 for inflating the interior of the finger cavity 1 .

[0040] The opposite sides of the side wall of the finger cavity 1 are respectively provided with a strain limiting layer 104 and a fiber winding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com