Maintenance-free wheel end front axle of sectional structure

A maintenance-free, segmented technology, applied in wheel hubs, transportation and packaging, vehicle parts, etc., can solve problems such as reducing the frequency of vehicle use, troublesome replacement of brake disc wearing parts, and increasing the cost of axle use, to ensure Bearing clearance, the effect of achieving maintenance-free and reducing the risk of failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

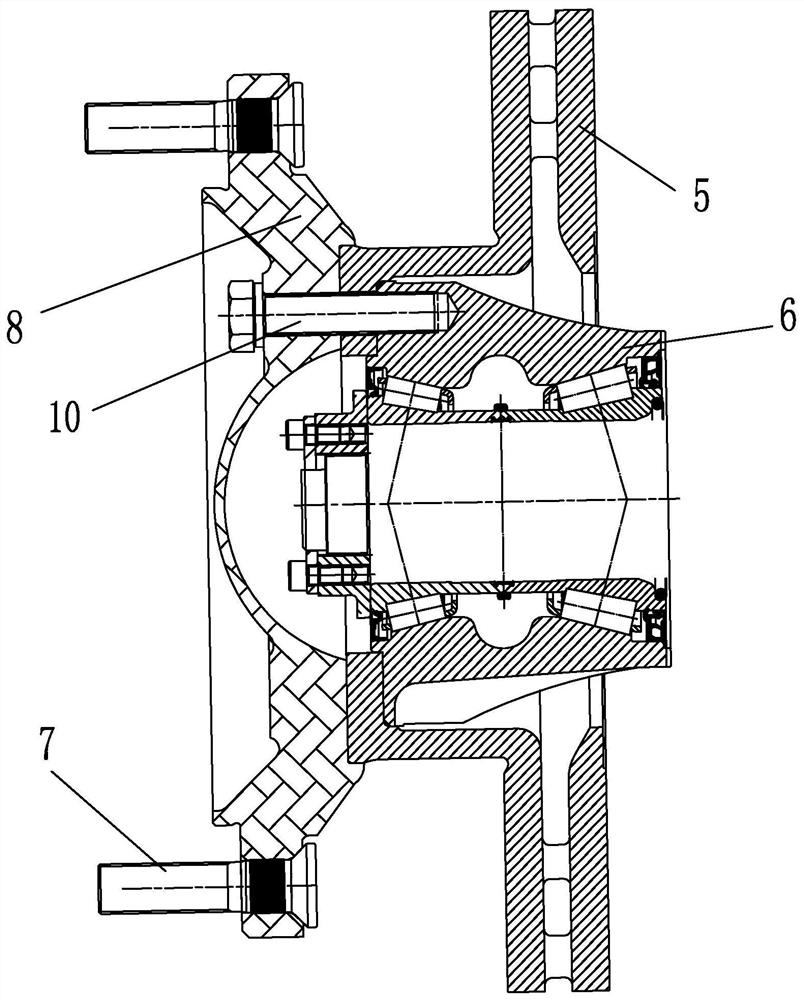

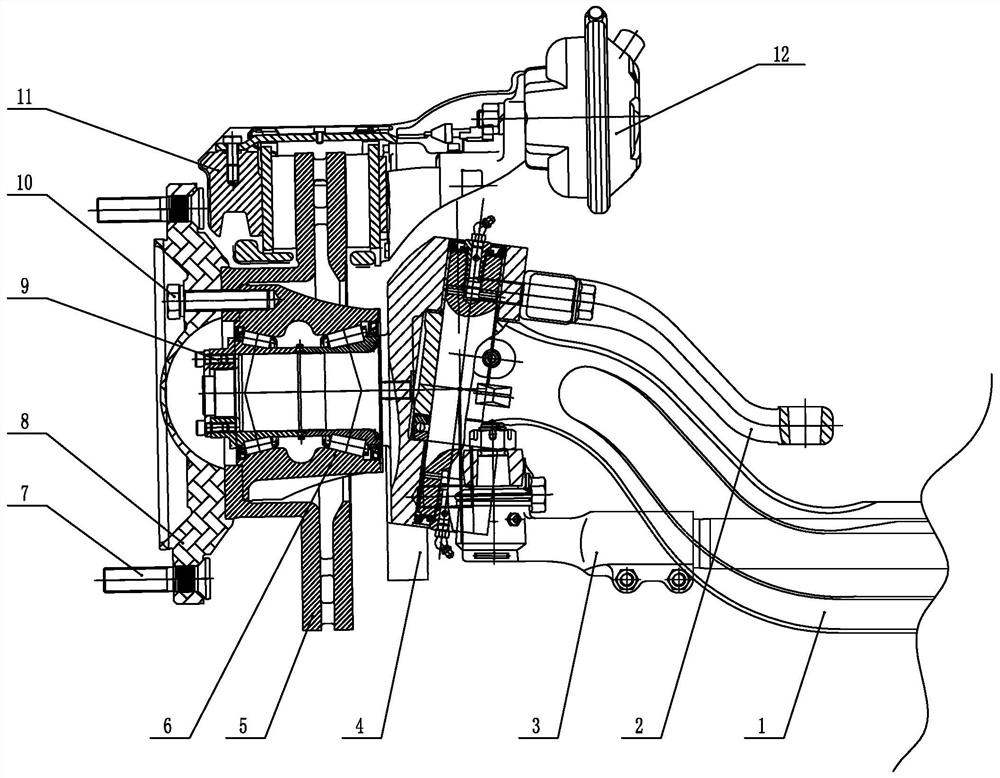

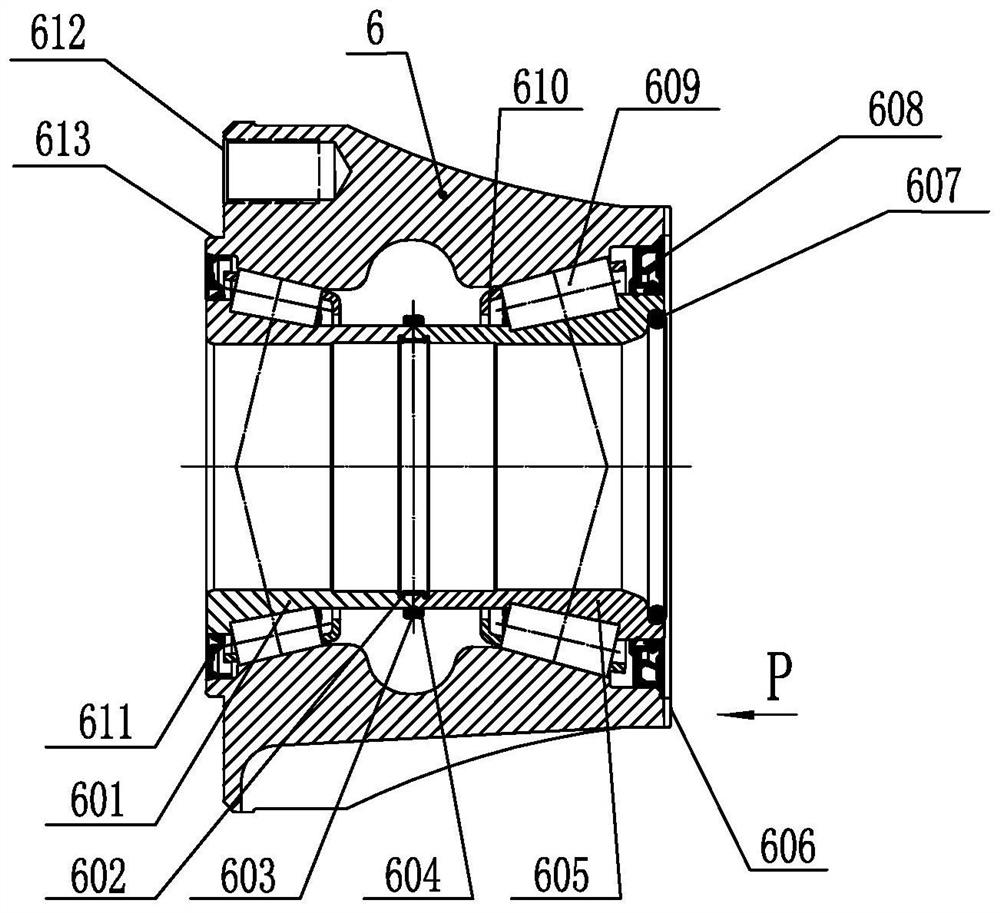

[0020] A maintenance-free wheel-end front axle with a segmented structure, including a hub and a brake disc. The hub is an integrated hub, the integrated hub is a bearingless outer ring, and the inner hub is equipped with an outer bearing inner ring, an inner bearing inner ring, rolling elements, a cage, a U-shaped adjusting ring, and a B and Z-shaped hub tile cover. Moving disc bonding surface A, integrated ABS ring gear, O-ring and sealing ring, the rolling elements are set on the cage, the U-shaped adjusting ring is set in the U-shaped groove, and the sealing ring includes inner sealing ring, outer sealing ring and The middle seal ring, each seal ring seals the place that needs to be sealed, and the Z-shaped brake disc is equipped with the inner hub fitting surface A, the hub tile cover fitting surface B, the outer hub cover fitting surface C, and the embedded flange and the friction surface of the brake disc, the outer hub cover of the hub is provided with an integrated hu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com