Road roller for road construction and use method thereof

A technology for road construction and road rollers, applied in the direction of roads, roads, road repair, etc., can solve problems such as road damage and large mass, and achieve the effect of reducing high-speed vibration and impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The following is attached Figure 1-8 The application is described in further detail.

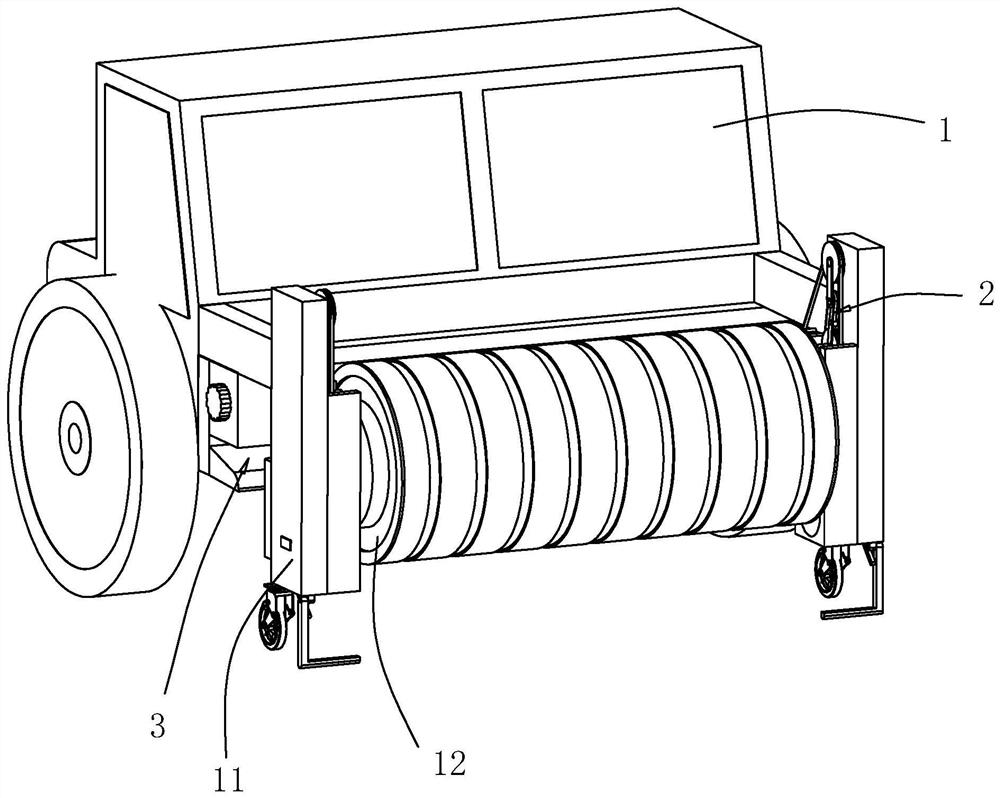

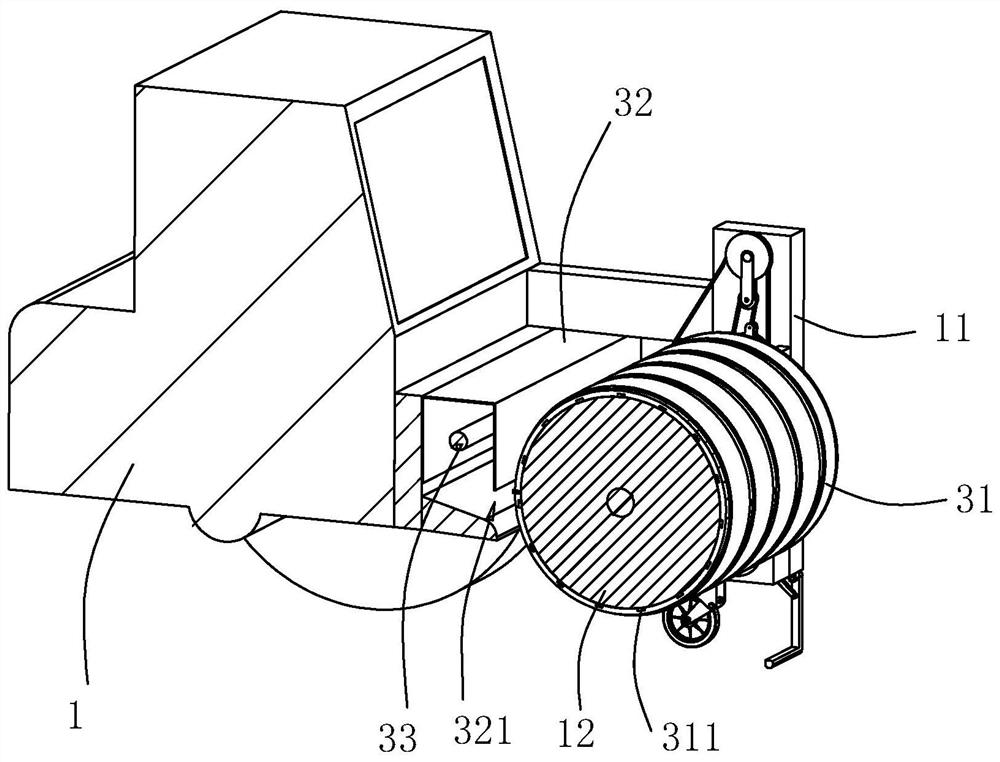

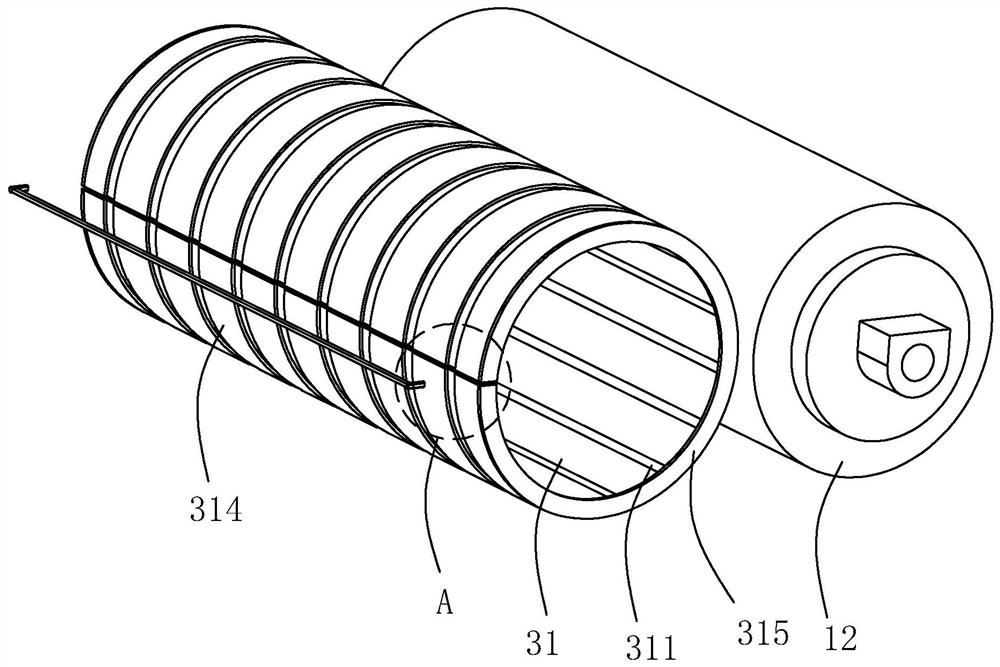

[0045] The embodiment of the present application discloses a road roller for road construction. refer to figure 1 and figure 2 , a road construction roller comprising a roller body 1, the two sides of the advancing direction of the roller body 1 are fixed with brackets 11, the bracket 11 is rotatably connected with a steel wheel 12, the steel wheel 12 is used to compact the road surface, the bracket 11 There is a lifting mechanism 2 that drives the steel wheel 12 to move vertically, and the side of the road roller body 1 close to the steel wheel 12 is equipped with a covering mechanism 3. The covering mechanism 3 includes a rubber pad for covering the steel wheel 12. 31; When the steel wheel 12 is not needed, the lifting mechanism 2 lifts the steel wheel 12, and then covers the rubber pad 31 on the coating mechanism 3 on the steel wheel 12, and the rubber pad 31 covers the steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com