Exhaust structure of clutch booster cylinder and clutch booster cylinder

A technology of booster cylinder and clutch, applied in clutch, transportation and packaging, fluid pressure actuating device, etc., can solve problems such as damage to clutch booster cylinder and reduction of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

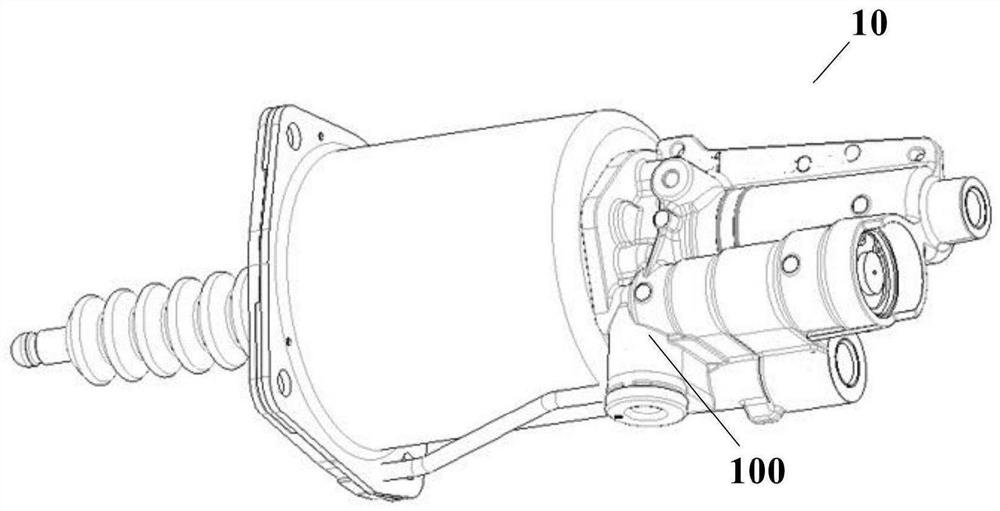

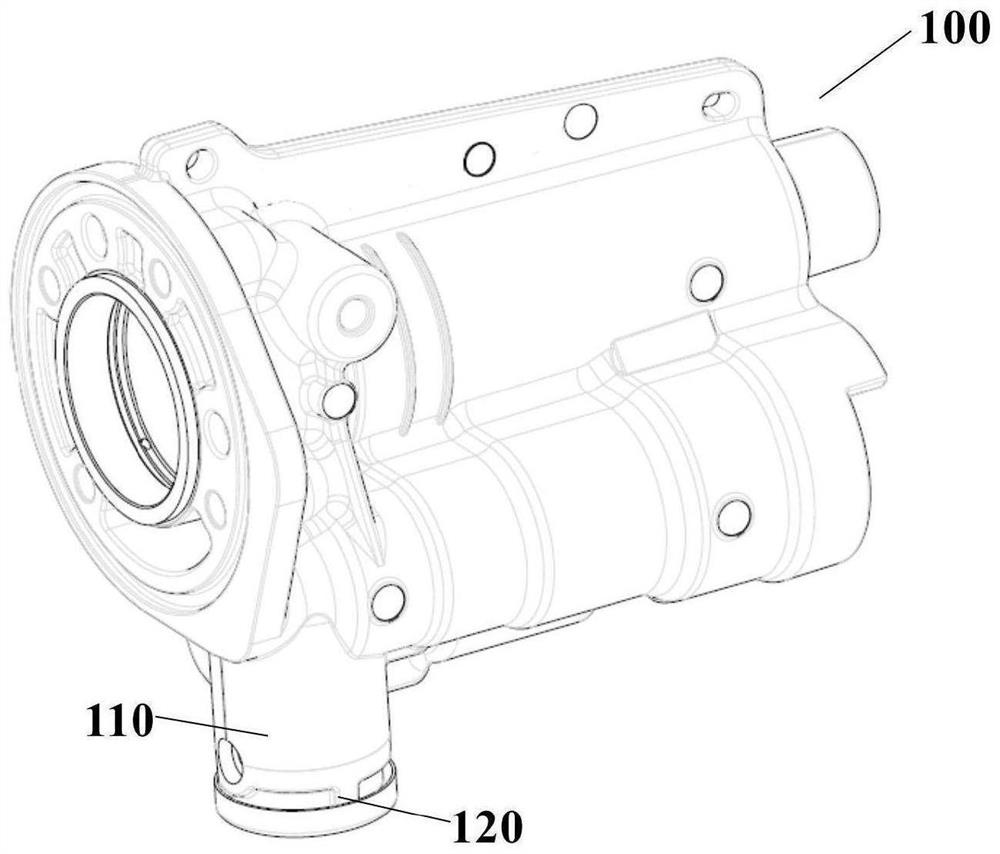

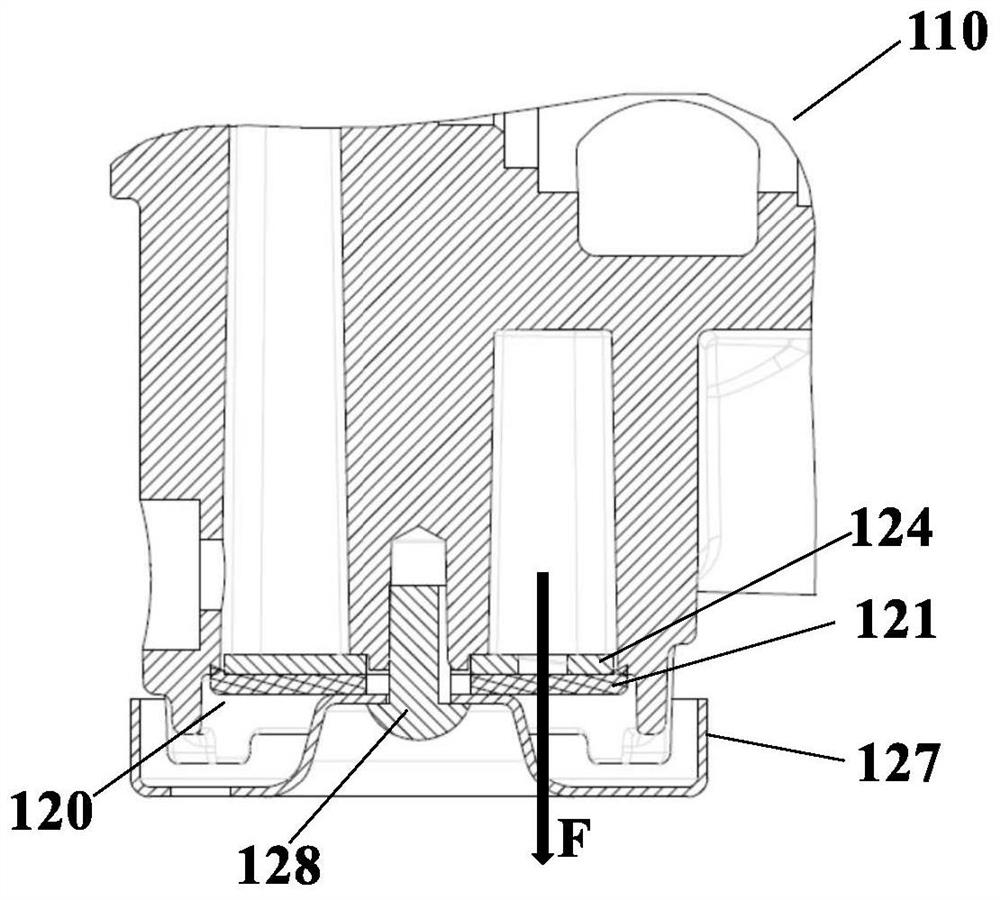

[0039] First, refer to Figure 1-6 The exhaust structure 100 of the clutch booster cylinder 10 according to the first embodiment of the present invention is described. figure 1As shown, the clutch booster cylinder 10 is equipped with an exhaust structure 100 . Such as Figure 2-4 As shown, the exhaust structure 100 is provided with an exhaust port 110 , and the non-return structure 120 can be installed on the exhaust port 110 . Here, the "non-return structure" refers to a structure configured to allow gas in the clutch booster cylinder to be exhausted but isolate foreign matter outside the exhaust port to prevent it from entering the clutch booster cylinder, and such a definition applies throughout. exist figure 2 , 3 , the non-return structure 120 has been installed to the exhaust port 110, and in Figure 4 The intermediate check structure 120 has not yet been installed to the exhaust port 110 .

[0040] The non-return structure 120 according to this embodiment is prov...

no. 2 example

[0047] Next, refer to Figure 7-9 The exhaust structure of the clutch booster cylinder according to the second embodiment of the present invention will be described. The exhaust structure of the clutch booster cylinder of the second embodiment is the same as that of the first embodiment in appearance. In fact, the second embodiment is a further improvement of the sealing enhancement structure of the elastic sealing gasket in the non-return structure of the first embodiment and the abutting portion of the exhaust port abutting against the sealing enhancement structure of the elastic sealing gasket. Improve. Therefore, for the sake of brevity, only differences from the first embodiment will be described in this embodiment, and illustration and description of the same parts will be omitted.

[0048] The non-return structure 220 according to this embodiment is provided with an elastic sealing gasket 221 and a rigid bracket 224, such as Figure 7 shown. Instead of the triangula...

no. 3 example

[0051] Next, refer to Figure 10-12 An exhaust structure 300 of a clutch booster cylinder according to a third embodiment of the present invention will be described. Such as Figure 10-12 As shown, the exhaust structure 300 is provided with an exhaust port 310, and a non-return structure 320 configured to allow the gas in the clutch booster cylinder to be exhausted but prevent foreign objects outside the exhaust port from entering the clutch booster cylinder can be installed to the exhaust port 310 superior. The non-return structure 320 includes an elastic sealing gasket 321 and a rigid bracket 324 . Different from the first and second embodiments, in this embodiment, along the exhaust direction F of the exhaust port 310 , a biasing structure 330 is provided downstream of the non-return structure 320 . Figure 11 The two dotted-line boxes in , roughly frame the non-return structure 320 and the biasing structure 330 of this embodiment respectively. exist Figure 10 , 11 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com