Management system based on oil depot automation and informatization process

A technology for management systems and oil depots, applied in the field of oil depot management systems, can solve problems such as the coordination and linkage between production control systems, business systems, and security systems, and achieve the effect of improving safety management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

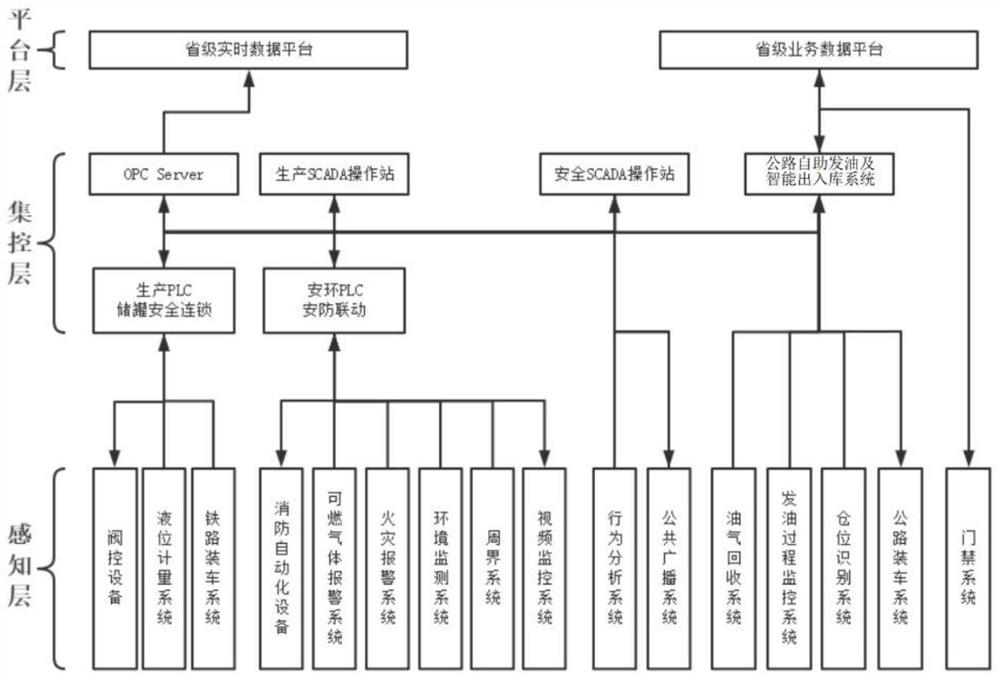

[0043] A management system based on the automation and informatization process of the oil depot. This system is based on the actual business operation status of the oil depot, and closely focuses on the two main lines of "production and safety" to improve production efficiency, reduce operating costs, enhance enterprise benefits, and ensure operation. Safety is the starting point to complete the construction; figure 1 As shown; the management management system includes a platform layer, a centralized control layer and a perception layer. The platform layer includes a provincial real-time data platform and a provincial business data platform. The centralized control layer is divided into a first-level centralized control layer and a second-level centralized control layer. The first-level centralized control layer includes OPC server, production SCADA operation station, safety SCADA operation station, highway self-service oil distribution and intelligent storage system; the provi...

Embodiment 2

[0064] A management system based on the automation and informatization process of oil depots. Various production operations in oil depots include pipeline oil collection operations, railway oil collection operations, railway loading operations, road oil collection operations, road oil delivery operations, storage Internal transfer operations, tank cleaning operations, water release operations, oil recovery operations, inventory, and non-moving tank inventory operations.

[0065] Among them, the operation process of pipeline oil transportation includes the following steps:

[0066] S1: The system automatically synchronizes the monthly pipeline transportation plan in the refined oil logistics system as the basis for tracking the monthly pipeline transportation plan. If the monthly plan is adjusted in the logistics system, it will be pushed to the system by the logistics system;

[0067] S2: After the logistics center receives the pipeline transportation batch plan from the regio...

Embodiment 3

[0081] A management system based on oil depot automation and informatization process, this embodiment makes the following improvements on the basis of embodiment 2: the railway oil collection operation process includes the following steps:

[0082] S1: The system automatically synchronizes the railway shipping information of the logistics system to generate a railway oil collection operation plan. For the transportation between large regions and provincial railway warehouses that have not maintained railway shipping information, the logistics center will maintain the railway in the refined oil logistics system Shipping information, the system automatically synchronizes and generates a railway oil collection operation plan; when the system generates a railway oil collection plan, it generates a train receiving operation ticket;

[0083] S2: The business team picks up the train according to the communication with the railway party, and feeds back the pick-up situation through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com