Weft yarn angle detection method and device based on carbon fibers and storage medium

An angle detection, carbon fiber technology, applied in the inspection of textile materials, textiles and papermaking, instruments, etc., can solve the problems of reducing product quality, production impact, the angle of the weft can not reach the normal angle, etc., to achieve the effect of ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

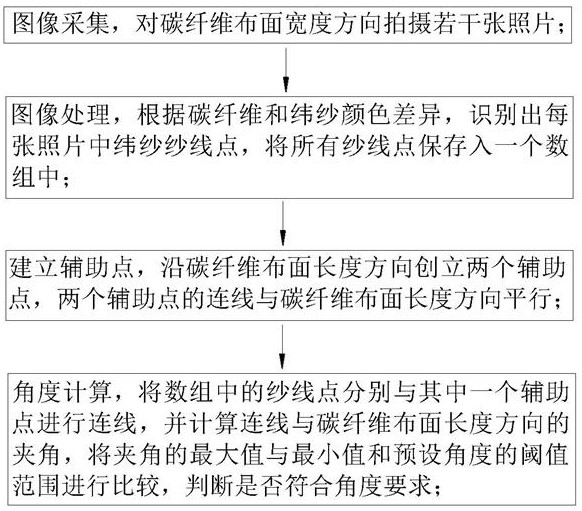

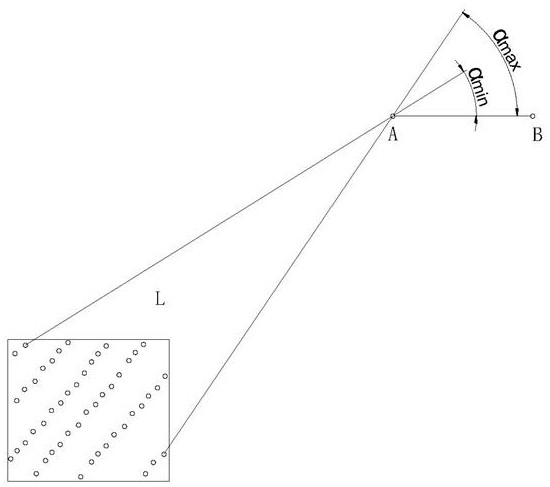

[0025] In this embodiment, take 45° weft as an example, such as Figures 1 to 2 Shown: a carbon fiber-based weft angle detection method, including the following steps:

[0026] Image collection, taking several photos in the width direction of the carbon fiber cloth;

[0027] Image processing, according to the color difference between carbon fiber and weft yarn, identify the weft yarn points in each photo, and save all the yarn points into an array;

[0028] Establish auxiliary points, create two auxiliary points along the length direction of the carbon fiber cloth surface, and the connection line of the two auxiliary points is parallel to the length direction of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com