Fixed line feed apparatus of ultrasonic probe in ultrasonic wave stress measurement system

A technology of stress measurement and ultrasonic probe, which is applied in the direction of measuring devices, measuring forces, instruments, etc., can solve the problem of inability to accurately control the coupling state of the probe and the component to be measured, the inability to ensure that the probe is consistent with the component to be measured, and affect the accuracy of ultrasonic testing methods, etc. problem, achieve the effect of reducing influence, low device cost and improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

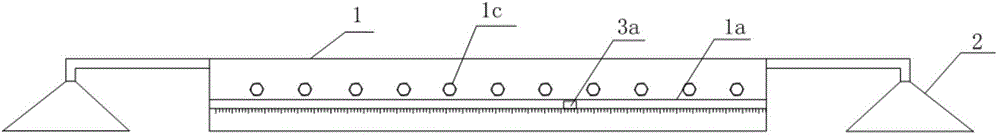

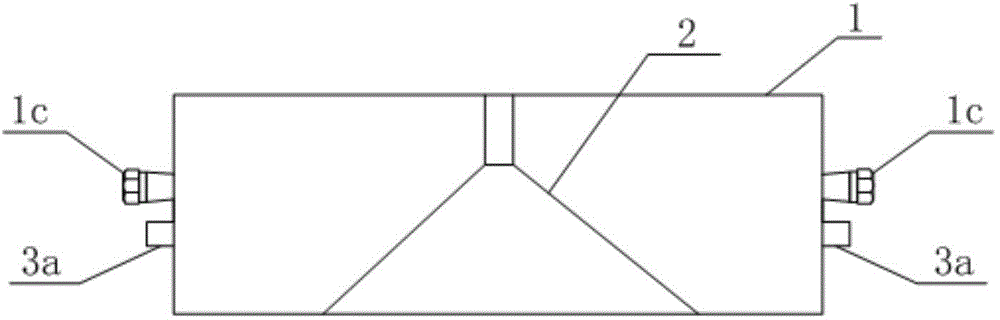

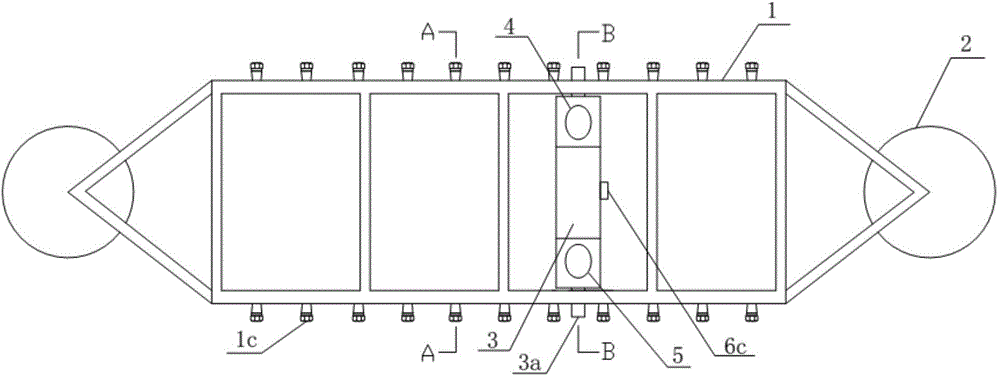

[0044] Figure 1-5 As shown, a specific embodiment of the present invention is: a fixed running device of an ultrasonic probe in an ultrasonic stress measurement system, comprising:

[0045] The track frame 1 with a "door"-shaped cross section is provided with horizontal through grooves 1a on opposite sides of the track frame 1 along the length direction, and the two horizontal through grooves 1a are located on the same horizontal plane; the upper part of the through groove 1a is along the horizontal The direction is provided with a row of tapered bolt holes 1b, and the maximum diameter of the tapered bolt 1c that cooperates with the tapered bolt holes 1b is greater than the maximum diameter of the tapered bolt holes 1b; the material that constitutes the tapered bolt holes 1b, the tapered bolt holes Between 1b and the through groove 1a and under the through groove 1a are elastic materials;

[0046] Fixed suction cups 2 fixed to both ends of the track frame 1 along the length ...

Embodiment 2

[0058] Figure 6 , Figure 7 As shown, another specific implementation of the present invention is: this embodiment is basically the same as Embodiment 1, the only difference is that the probe fixing cavity 4 described in this example is embedded and fixed in the probe fixing wedge 3 The upper left area; the probe fixing cavity 2 5 is embedded and fixed in the upper right area of the probe fixing wedge 3 .

[0059] Use effect of the present invention can be verified and explained by following test:

[0060] Select the aluminum alloy material A7N01S-T5, 700*230 butt joint test plate commonly used in high-speed trains, and arrange the residual stress test points according to the same distance, as Figure 6 mentioned.

[0061] Install the fixed running device in the above method, connect the ultrasonic generator to the ultrasonic testing system, and conduct residual stress test on points 1-7. The test results are shown in the table below.

[0062] test point

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com