Elevator landing door reinforcing rib production system

A production system and reinforcing rib technology, used in metal processing equipment, feeding devices, positioning devices, etc., can solve the problem of inability to produce two types of reinforcing ribs, and reduce the time for manual shearing and manual transfer. Product quality, the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical means, creative features, goals and functions achieved by the present invention clearer and easier to understand, the present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments:

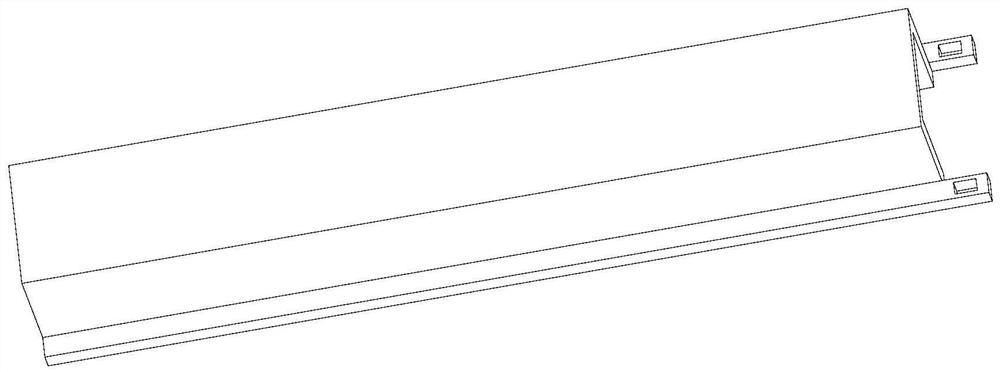

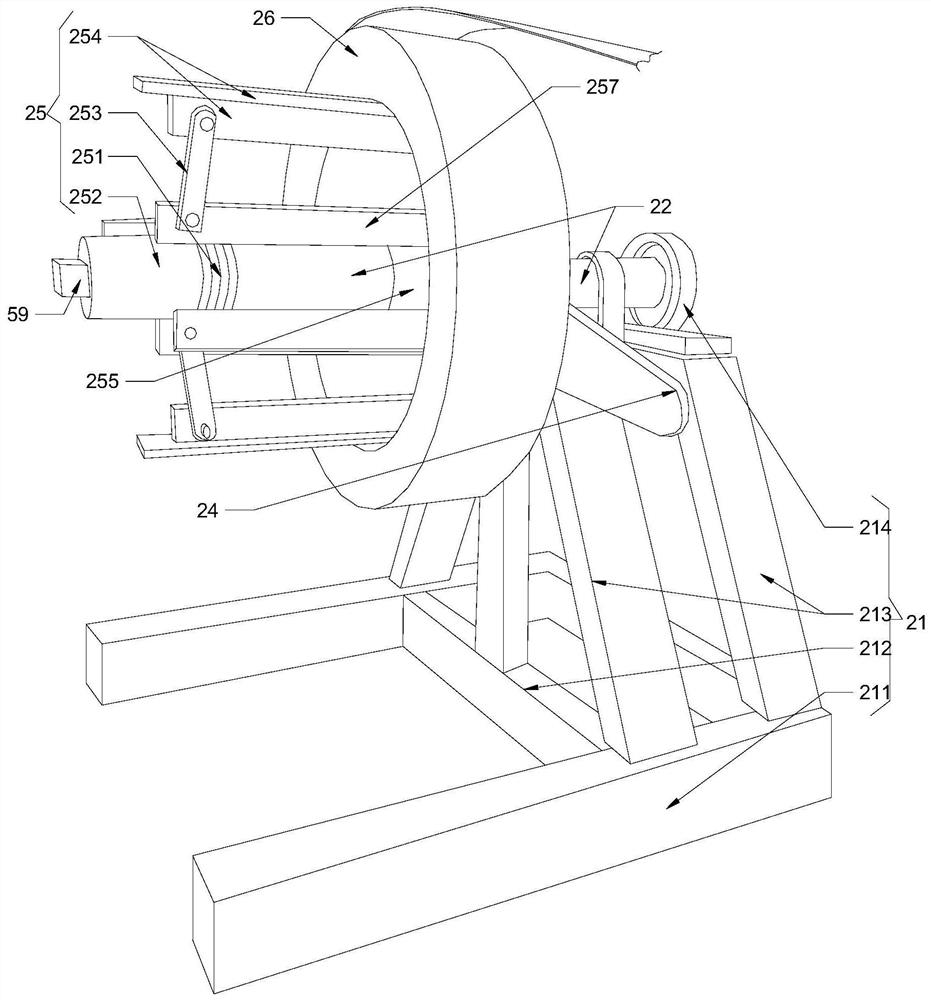

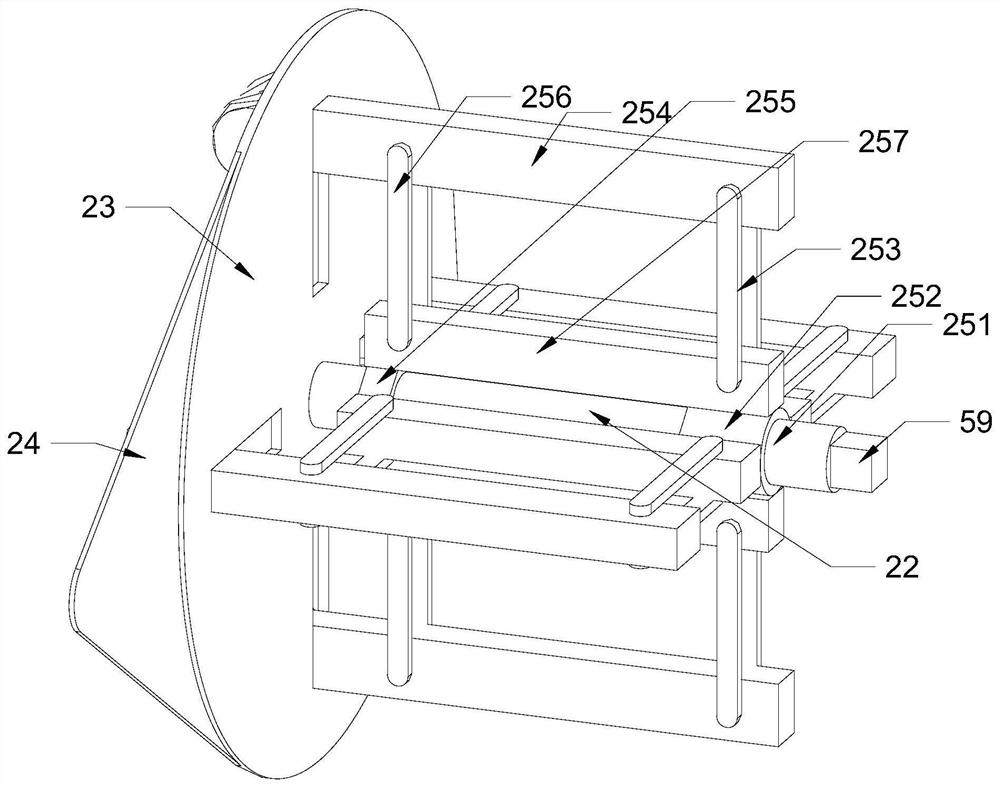

[0033] like Figure 1 to Figure 10 As shown, the present invention discloses a production system for reinforcing ribs of elevator landing doors, comprising: a rolling plate installation device, which is used to install steel plate coils 26; a rolling device, whose input end is located next to the rolling plate It is used to roll the steel plate into a "Ji" shape; and a punching device, which is used to cut the reinforcing ribs of the adjacent two layers of doors and punch the side holes at the joints of the reinforcing ribs of the adjacent two layers of doors.

[0034] The coil plate installation device includes: a first support base 21, a support shaft 22, a close-fitting disc 23, an auxiliary rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com