Suction cup device

A technology for suction cups and cover plates, applied in positioning devices, clamping, support, etc., can solve problems such as low operating efficiency, complex structure, cumbersome and complicated operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The application will be further described below in conjunction with the accompanying drawings and preferred embodiments, but the implementation of the application is not limited thereto.

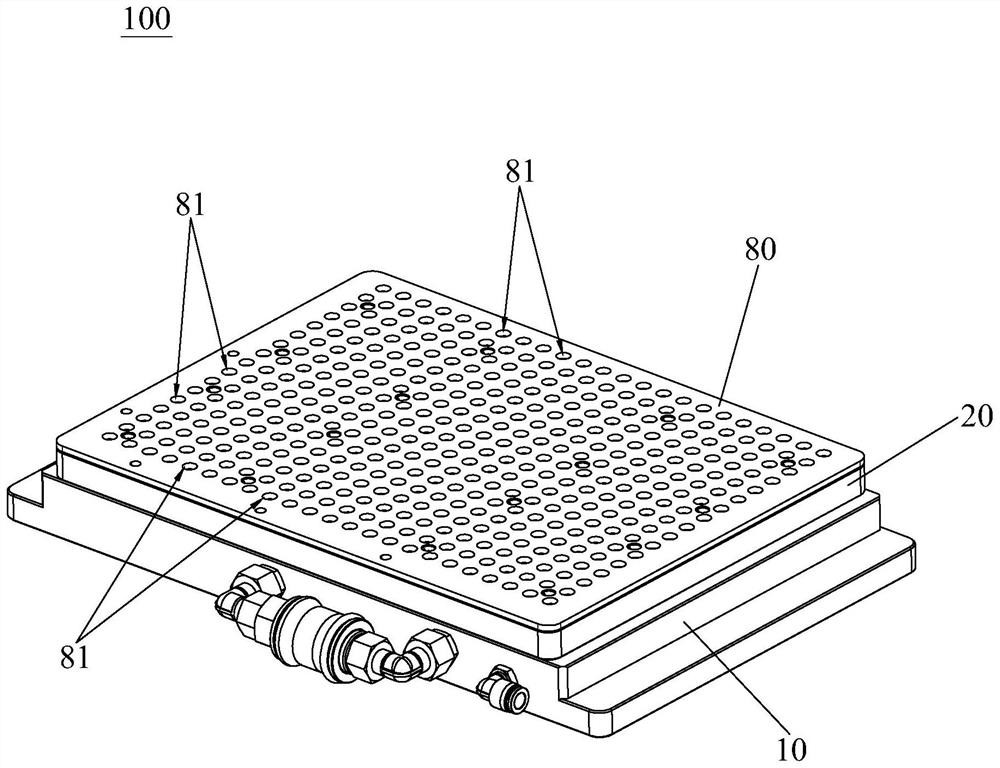

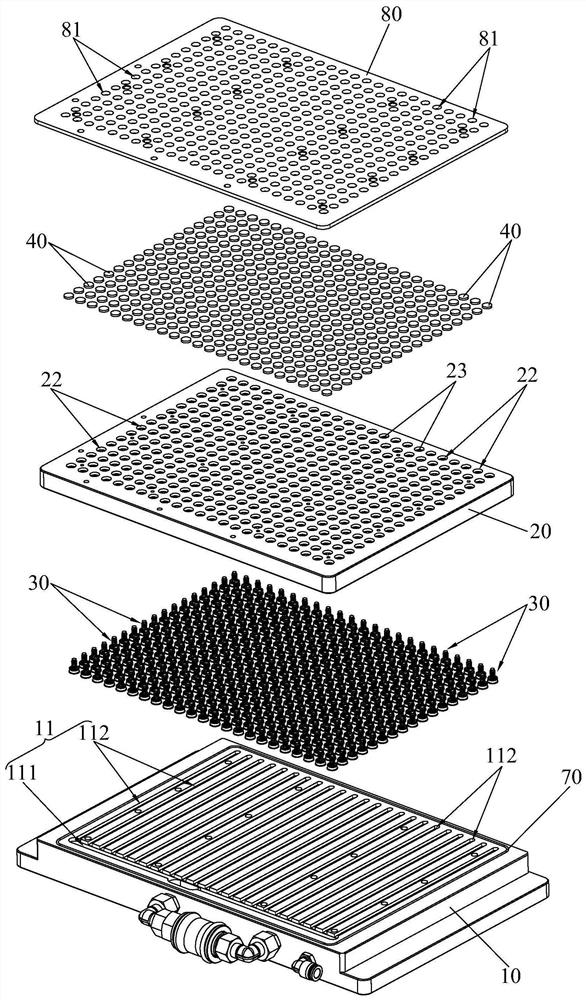

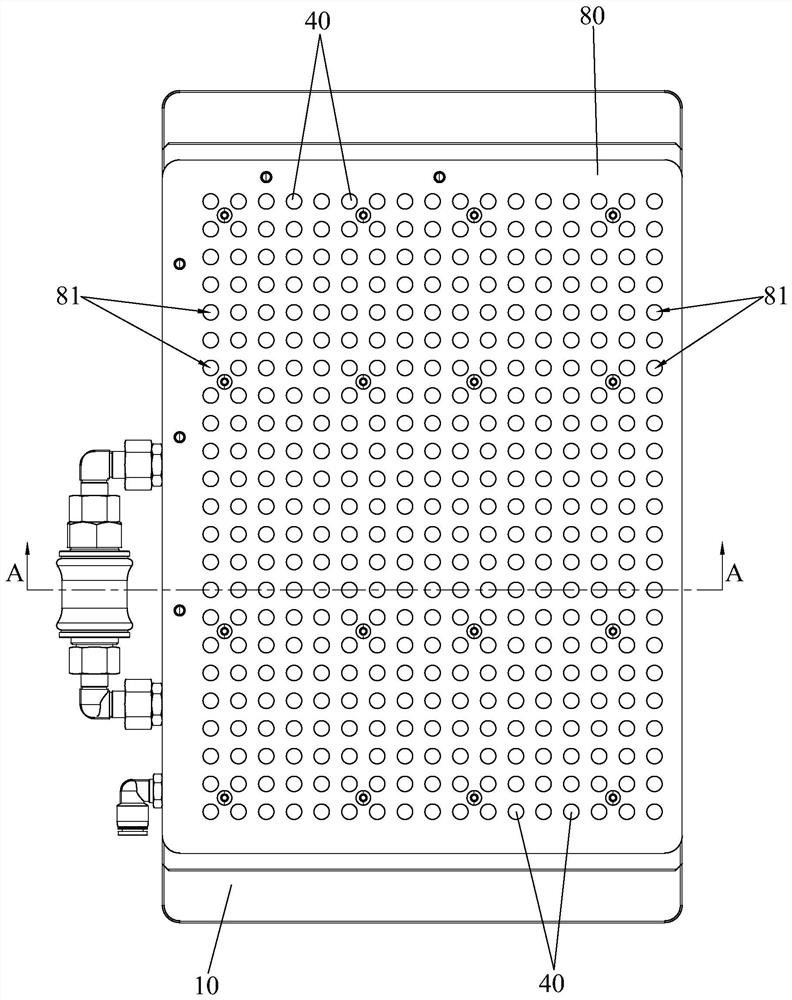

[0026] see Figure 1 to Figure 6 , the base 10 of the suction cup device 100 of the present application, the cover plate 20 and some air-tight components 30, the top of the base 10 is provided with a ventilation groove 11, the cover plate 20 is airtight and fixedly covered on the top of the ventilation groove 11, and the ventilation groove 11 A ventilation chamber (not marked in the figure) is formed between the bottom of the cover plate 20, the ventilation chamber is connected to an external vacuum pumping device, and the venting chamber is vacuumed by the external vacuum pumping device, and the external The specific structure of the vacuum pumping device is well known to those skilled in the art, so details will not be repeated here. The bottom of the cover plate 20 is vertically u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com