Polyester liner, forming die and forming method thereof

A technology for forming molds and polyester, which is applied in the field of polyester molds, can solve the problems of large space occupation and the inability to make multiple liners at the same time, and achieve the effect of reducing land occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

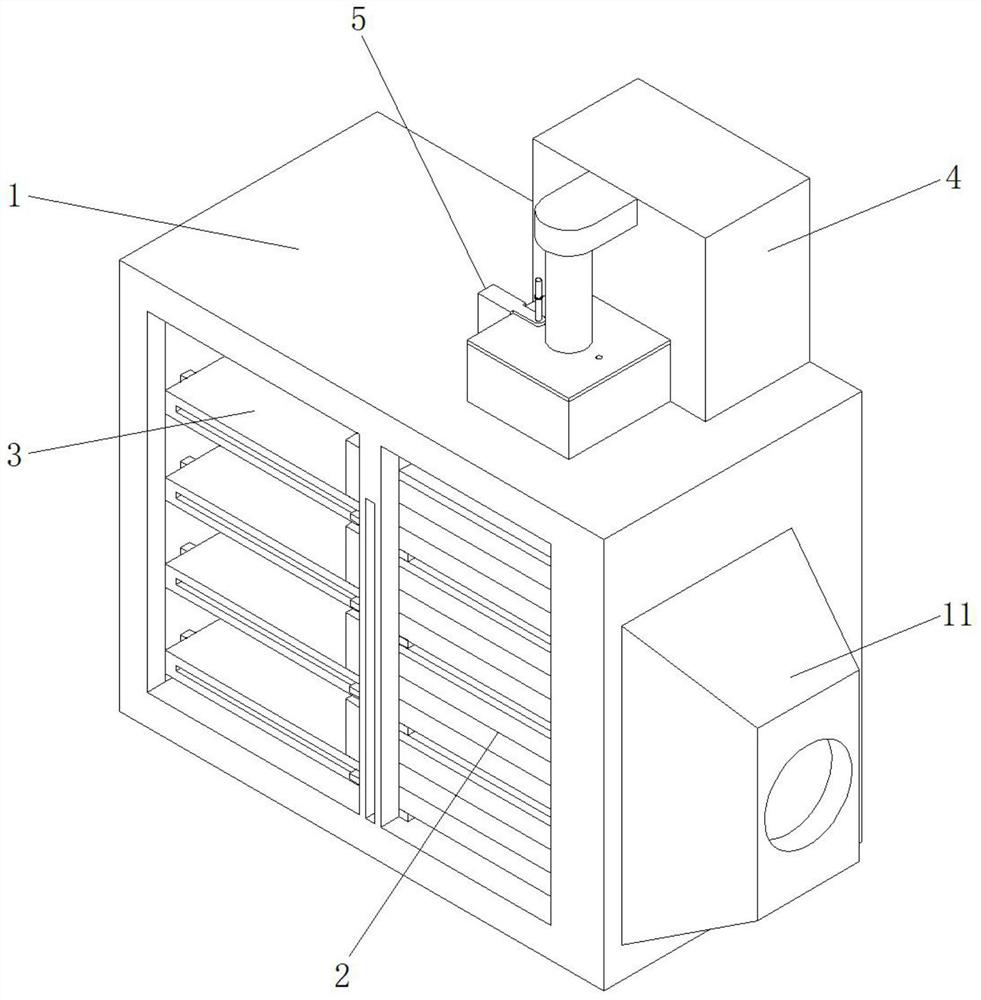

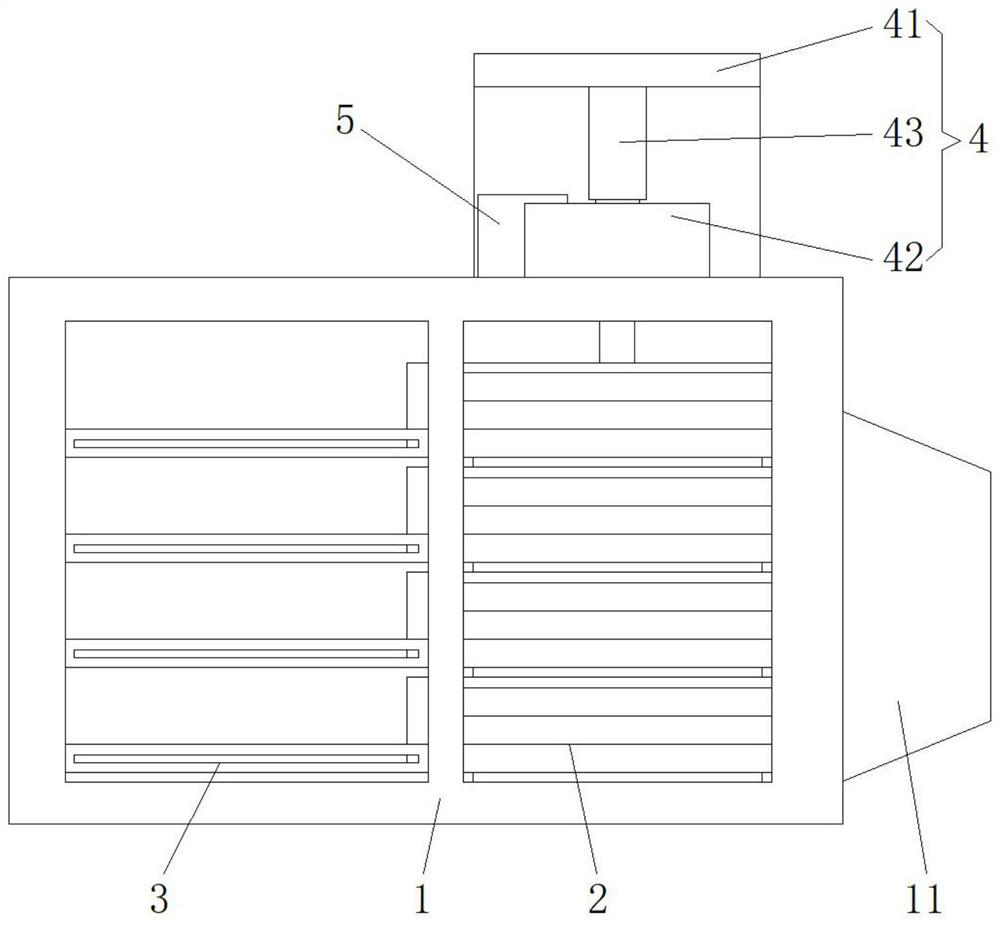

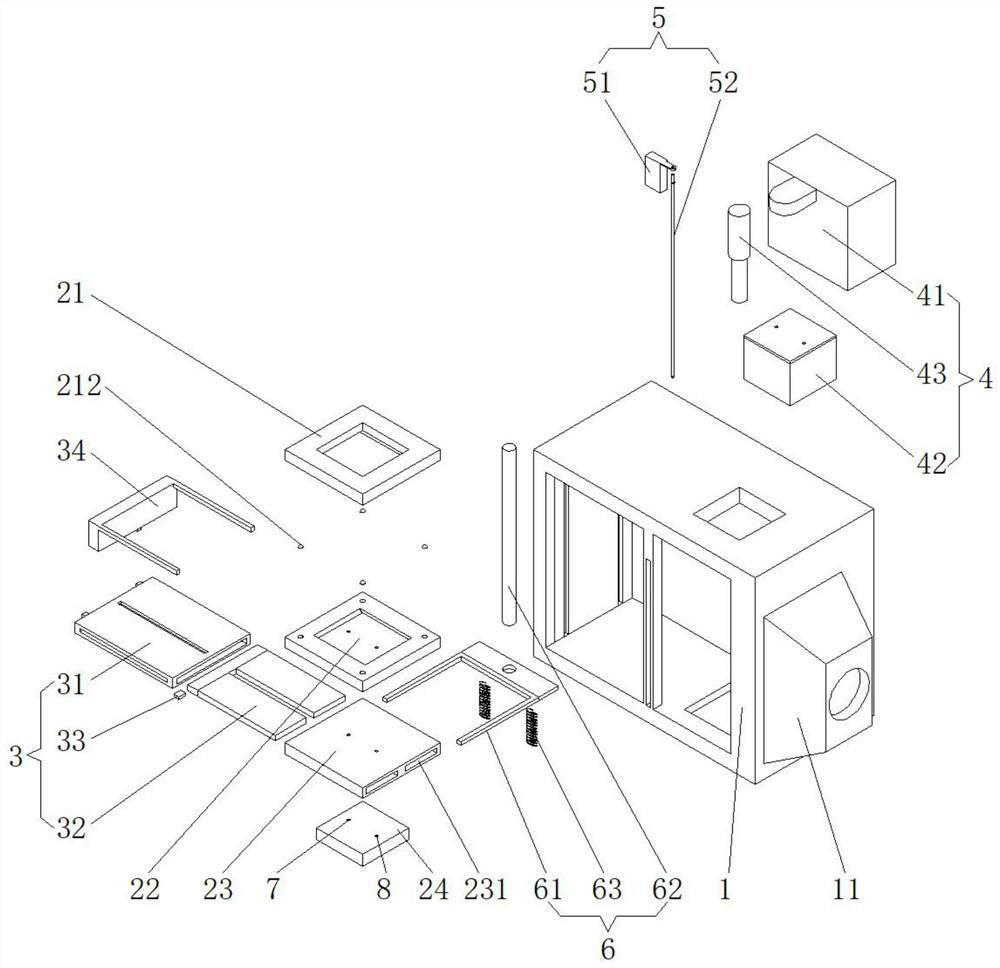

[0030] see Figure 1-11 , this embodiment provides a polyester gasket, a molding die and a molding method thereof, including a main body 1 of the mould.

[0031] The main body 1 includes two chambers, one of which is fixedly installed with a placement mechanism 6 , and the other chamber is slidably installed with a heating mechanism 3 .

[0032] Wherein, placement mechanism 6 comprises placement frame 61, positioning rod 62 and spring 63, and placement frame 61 is set to a plurality of, and one side socket of multiple placement frame 61 is installed on positioning rod 62, and aligns and discharges up and down, placement frame 61 A sizing mechanism 2 is slidably installed above, and a spring 63 is fixedly installed below the placement frame 61 and on both sides of the positioning rod 62 for providing elastic force to the placement frame 61 .

[0033] The heating mechanism 3 comprises a storage plate 31, a heating chip 32 and a control block 33 for controlling the heating chip ...

Embodiment 2

[0052] see Figure 1-7 , further improvements have been made on the basis of Example 1:

[0053] A partition plate 34 is fixedly mounted on the upper end of the heating plate 32 , and the partition plate 34 slides above the storage plate 31 through the movement of the heating plate 32 , and the air duct 11 is fixedly mounted on one side of the main body 1 .

[0054] Wherein, the receiving plate 31 is used to separate a plurality of sizing mechanisms 2, so that when the sizing mechanism 2 is heated by the heating mechanism 3, the extruding plate 24 and the pressing plate 42 are not completely submerged in the groove of the upper sizing plate 21. When the sheet 32 is separated from the temperature guide hole 231, the partition plate 34 is separated from the shaping mechanism 2 at the same time. At this time, the pressing mechanism 4 performs secondary pressing to discharge excess melt and gas in the inner cavity 211.

[0055] After the pressing mechanism 4 is pressed for the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com