Mold powder automatic adding system for crystallizer

A technology of automatic adding and mold slag, which is applied in the field of mold slag adding, can solve the problems that personnel cannot move normally, cannot form closed-loop control, and the operation coverage is large, so as to reduce the timing of slag addition, ensure smoothness, and solve the problem of occupying The effect of large space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

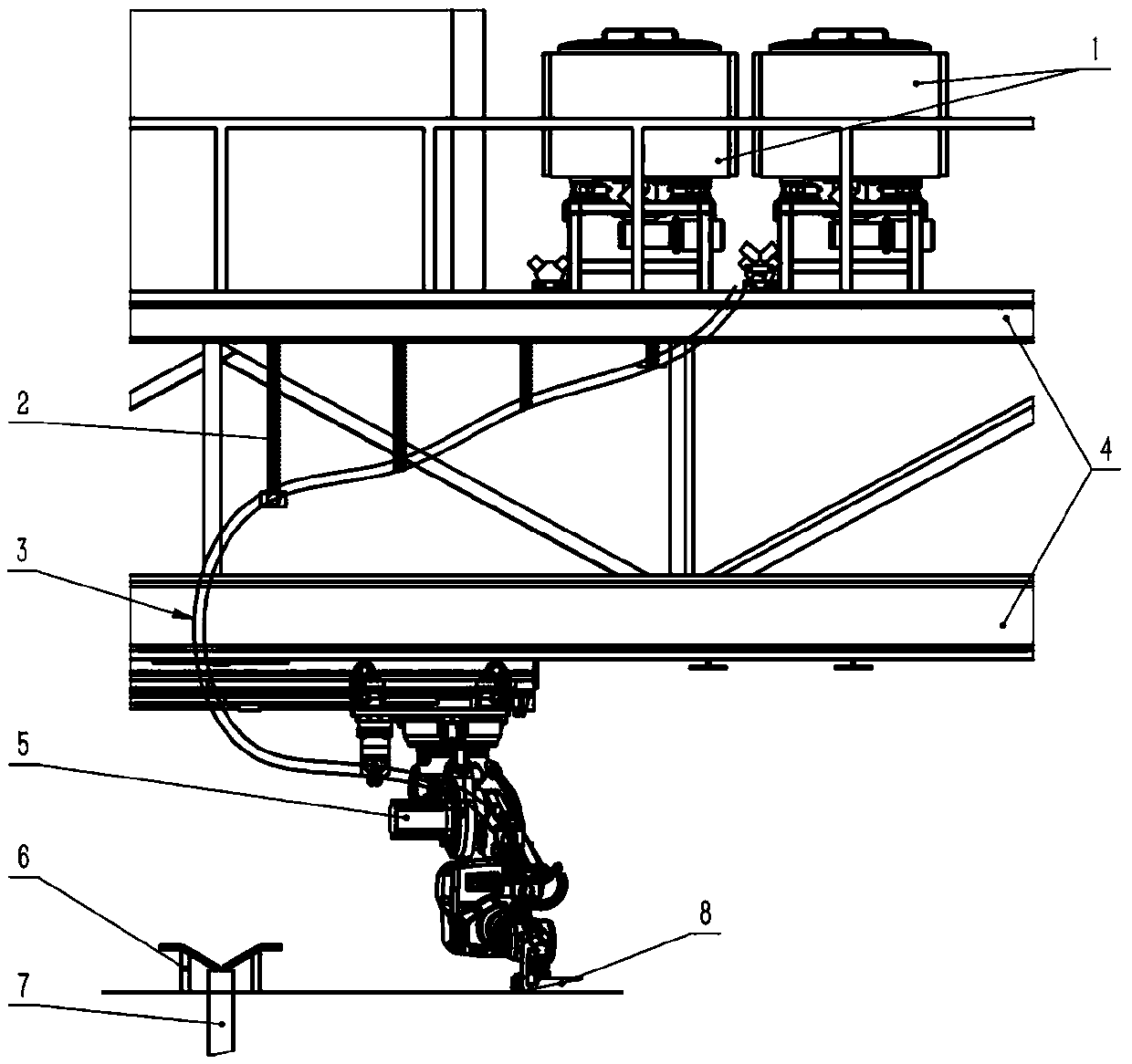

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings.

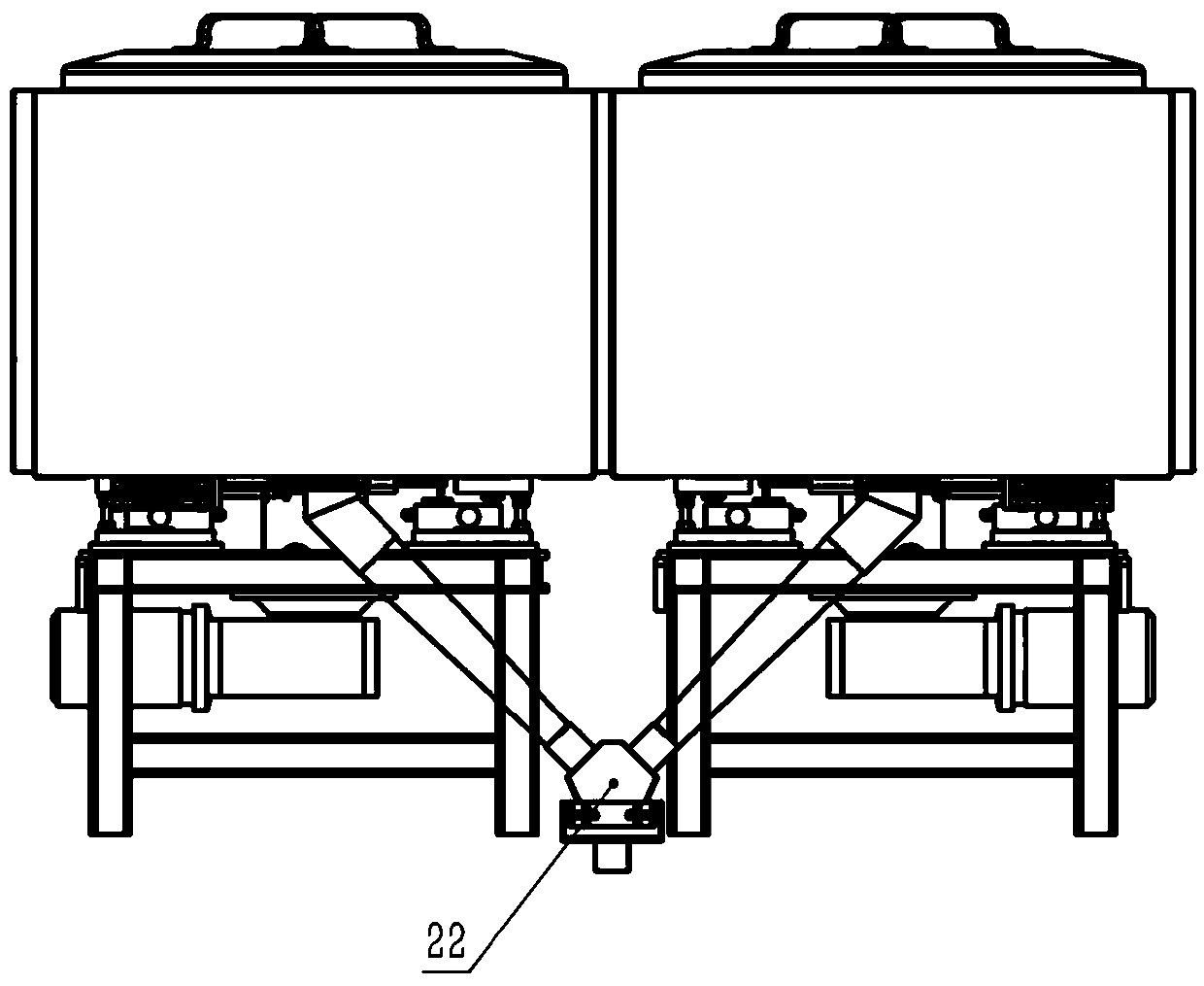

[0022] Such as Figure 1-4 As shown, the system for automatically adding mold slag to the crystallizer of the present invention includes a control system, a silo 1, a feeding pipe 3, a frame 4, a robot 5, an annular slag adding tool 6, a screw conveyor 8, an infrared detection device, and a mobile device Control terminal, safety scanner, alarm device; frame 4 includes upper frame and lower frame; feed bin 1, feeding pipe 3, robot 5 are arranged from top to bottom, feed bin 1 is fixed on the upper frame, feed bin 1 is connected to the feeding pipe 1, the feeding pipe 1 is connected to the screw conveyor 8, and the screw conveyor 8 is fixed on the robot 5; the driving device of the screw conveyor 8 is a servo motor;

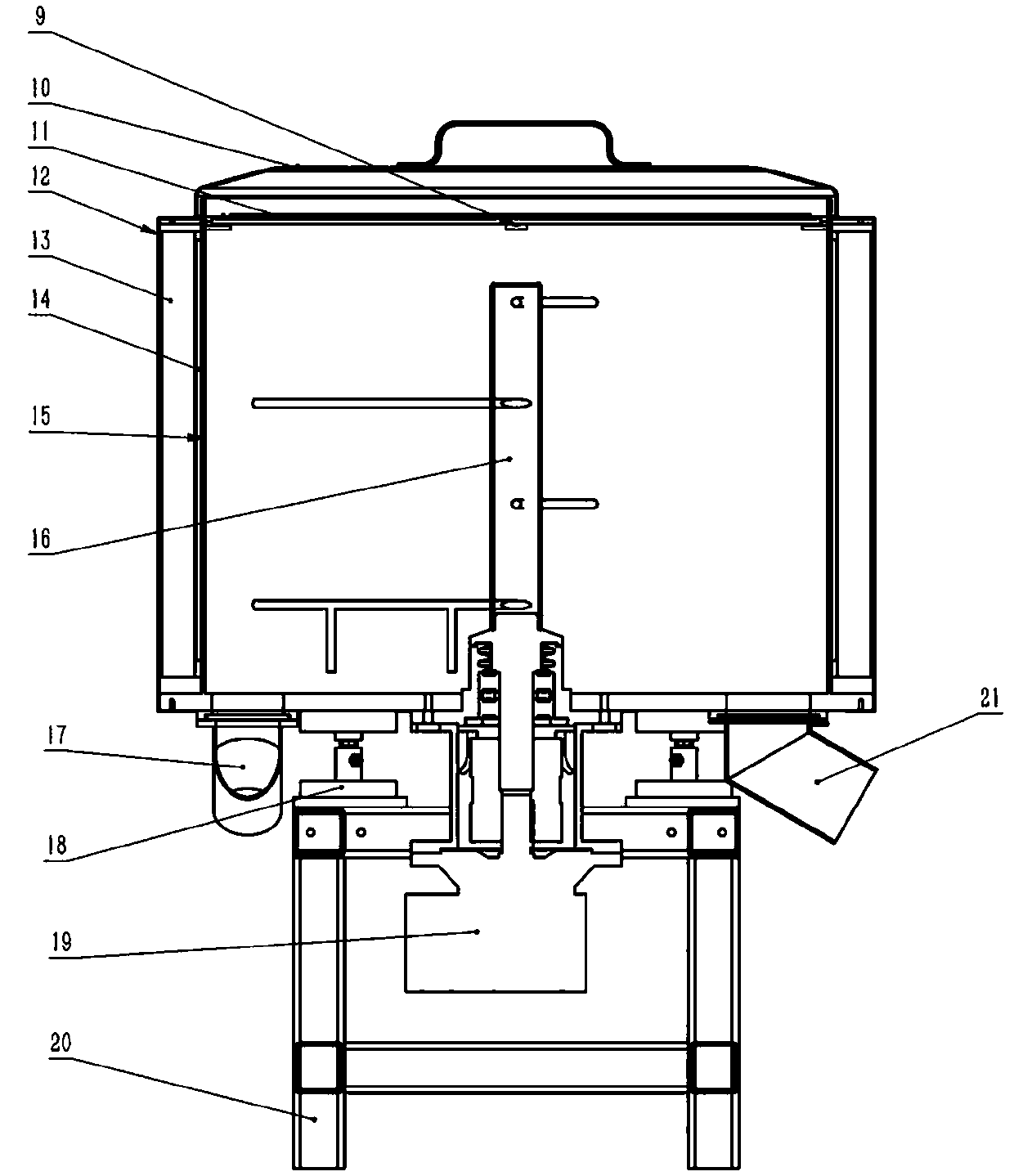

[0023] There are two silos, each of which is equipped with a temperature sensor 9, a silo cover 10, a protective net 11, a protective shell 12, an inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com