Epoxy foam glue preparation device and epoxy foam glue preparation method

An epoxy foam and glue technology, which is applied in chemical instruments and methods, mixers with rotary stirring devices, and accessories of mixers, etc., can solve the problems of low perfusion assembly efficiency, different foaming quality of rubber materials, and uneven stirring speed. , to solve the problem of poor foaming quality of the rubber compound, the same foaming quality of the rubber compound, and uniform stirring speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

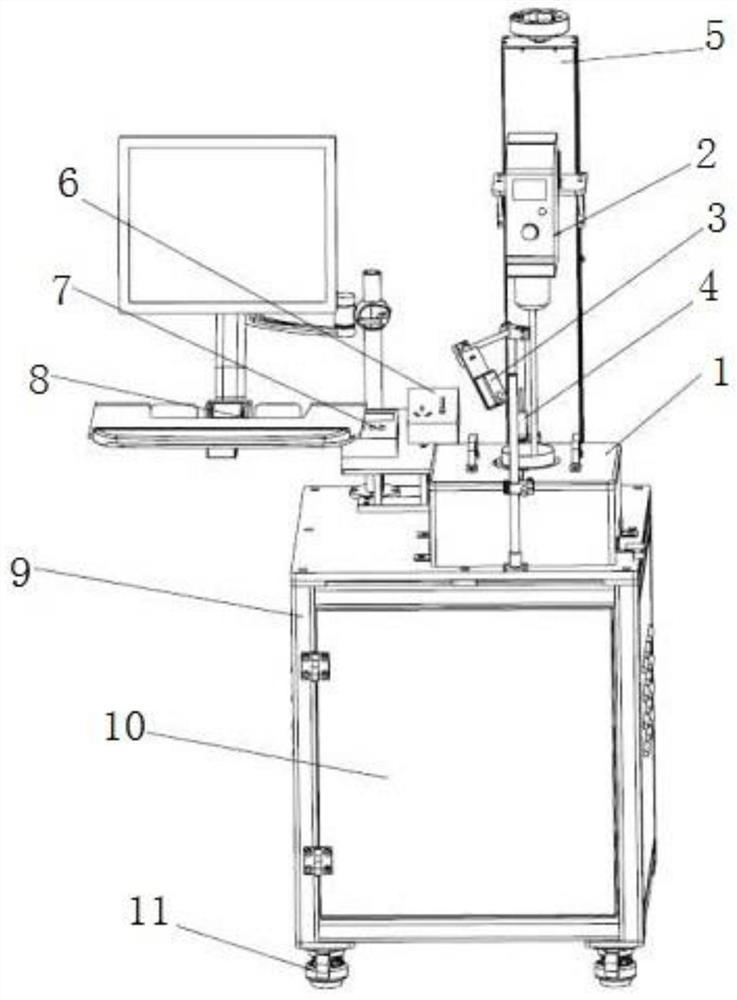

[0030] see figure 1 shown.

[0031] A kind of epoxy foam glue preparation device of the present invention comprises:

[0032] The constant temperature heater 1 composed of the heating water tank can realize heating after the heating water tank is powered on. The constant temperature heater 1 is equipped with a mixing bucket containing epoxy foam glue. The mixing bucket is a stainless steel mixing bucket. 70 ~ 80 ℃ range constant;

[0033] The rotating power part 2 that can rotate automatically is located above the constant temperature heater 1. The rotating end of the rotating power part 2 is equipped with a stirring rod extending into the mixing tank. The rotating power part 2 uses a motor. rotate.

[0034] Because the rotating power part 2 rotates and drives the stirring rod to extend into the mixing barrel for stirring, it c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com