Computer covering type protective film positioning and pasting device

A protective film and covering technology, which is applied in the field of computer covering protective film positioning and sticking devices, can solve the problems of the protective film generating air bubbles, being prone to wrong sticking, and being unable to be removed, and achieving the effect of preventing bubbles and avoiding sticking crookedly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

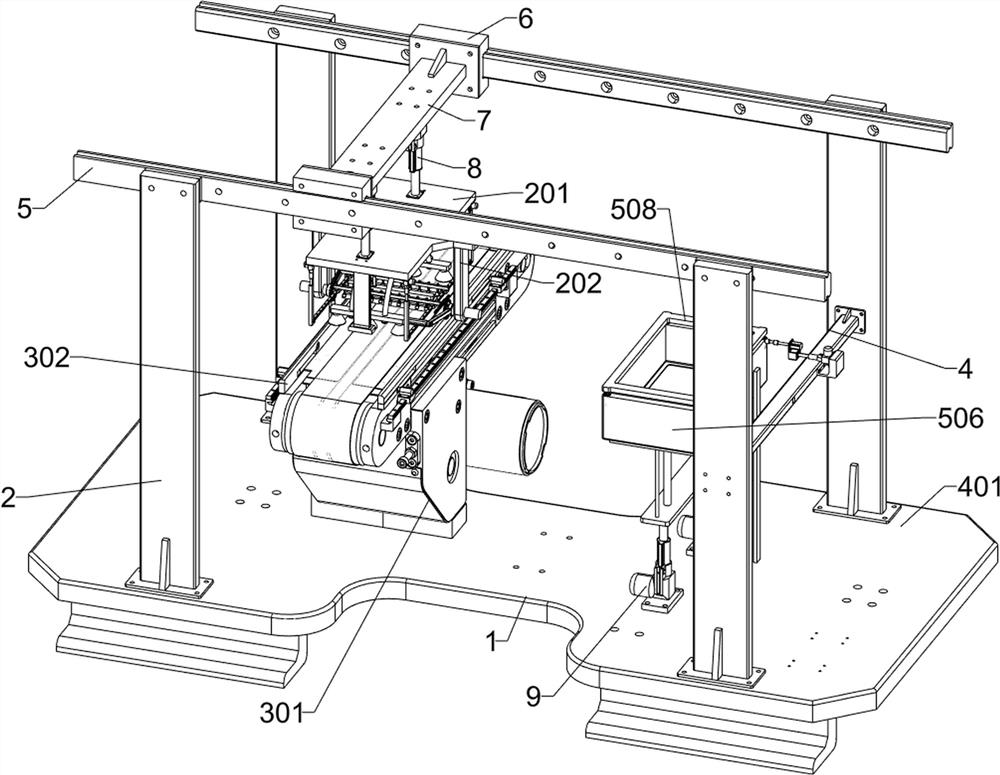

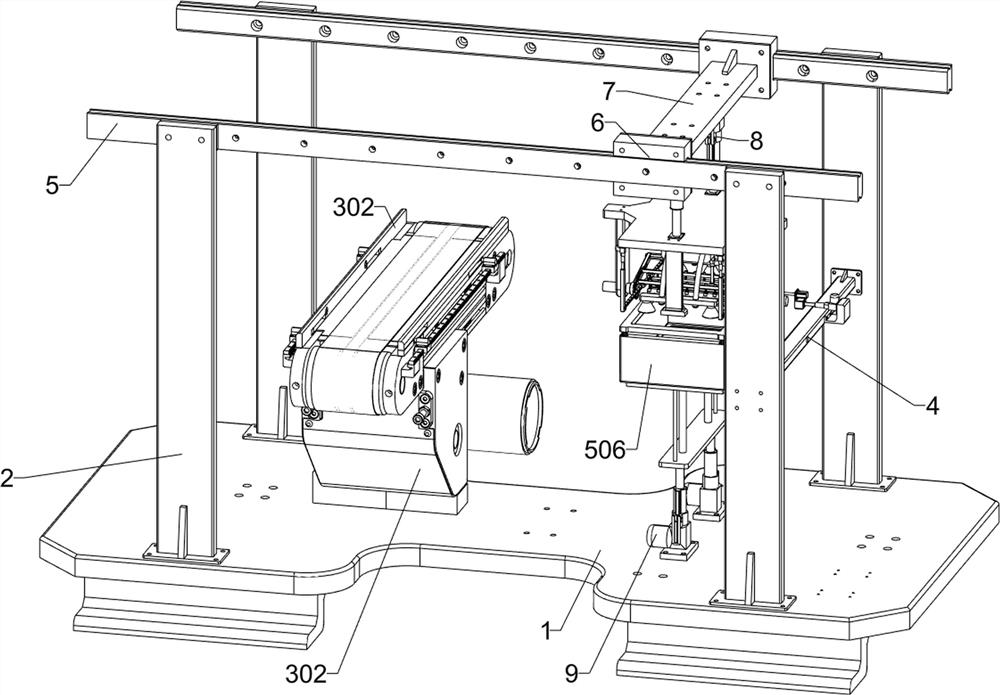

[0035] A computer-covered protective film positioning and pasting device, such as Figure 1-3 As shown, it includes a base frame 1, a first support plate 2, a moving assembly and a film assembly, four first support plates 2 are connected by square bolts above the base frame 1, and the upper parts of the four first support plates 2 are connected with a mobile assembly. A film assembly is installed on the moving assembly, and the moving assembly is used to drive the film assembly to move up, down, left, and right, and the film assembly is used to cover the protective film on the back cover of the computer.

[0036] When in use, transfer the computer that needs to be pasted to the bottom of the film component, with the back cover of the computer facing upwards, and at the same time, the moving component drives the film component to move to the right to take a protective film for pasting, and then return to the Figure 1 In the initial position shown, when the film sticking compon...

Embodiment 2

[0038] On the basis of Example 1, such as figure 1 with Figure 4-6 As shown, the film assembly includes a mounting plate 201, a first fixing plate 202, a first transmission rod 203, an L-shaped connecting rod 205, a hollow plate 206, a suction cup 207, an air module 208, a connecting hose 209, and a third electric push rod 210, the first connecting plate 211, the first back-moving spring 212 and the arc-shaped pressing plate 213; the lower part of the moving assembly is connected with a mounting plate 201, and the middle left and middle right of the mounting plate 201 are fixedly connected with a first fixed plate 202, two A first transmission rod 203 is connected to the bottom of each first fixed plate 202, and an L-shaped connecting rod 205 is fixedly connected to the opposite side of the outer surface of the two first transmission rods 203, and the two L-shaped connecting rods 205 are connected to the mounting plate 201. The center points of the two L-shaped connecting ro...

Embodiment 3

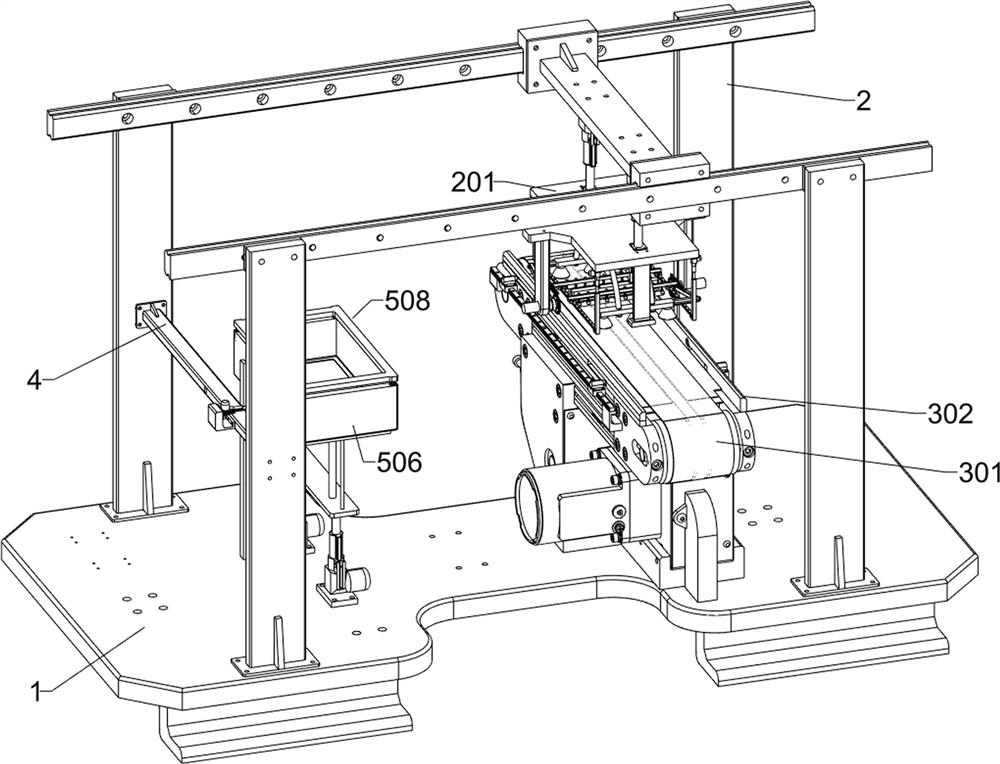

[0042] On the basis of Example 2, such as figure 1 with Figure 4-8 As shown, the film sticking assembly also includes a fourth electric push rod 214, a second fixed plate 215, a second electric guide rail 216, a first electric slider 217, a second connecting plate 218, a limit slide bar 219, and a second return spring 220, arc-shaped piece 221 and elastic tube 222, a fourth electric push rod 214 is fixedly connected to the four corners below the mounting plate 201, and a second fixing plate 215 is bolted to the lower part of each fourth electric push rod 214, and the left side A second electric guide rail 216 is fixedly connected to the bottom of the two second fixed plates 215 on the right side and the second fixed plate 215 on the right side, and two symmetrical first electric sliders are slidably connected to the two second electric guide rails 216 217, a second connecting plate 218 is fixedly connected to the two first electric sliders 217 in the front, and a second conn...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap