Spliced wiring wall for downhole operation

A wall and wall panel technology, applied to underwater structures, buildings, artificial islands, etc., can solve problems such as line corrosion, hidden safety hazards, time-consuming and labor-intensive, and achieve the effect of personalized settings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

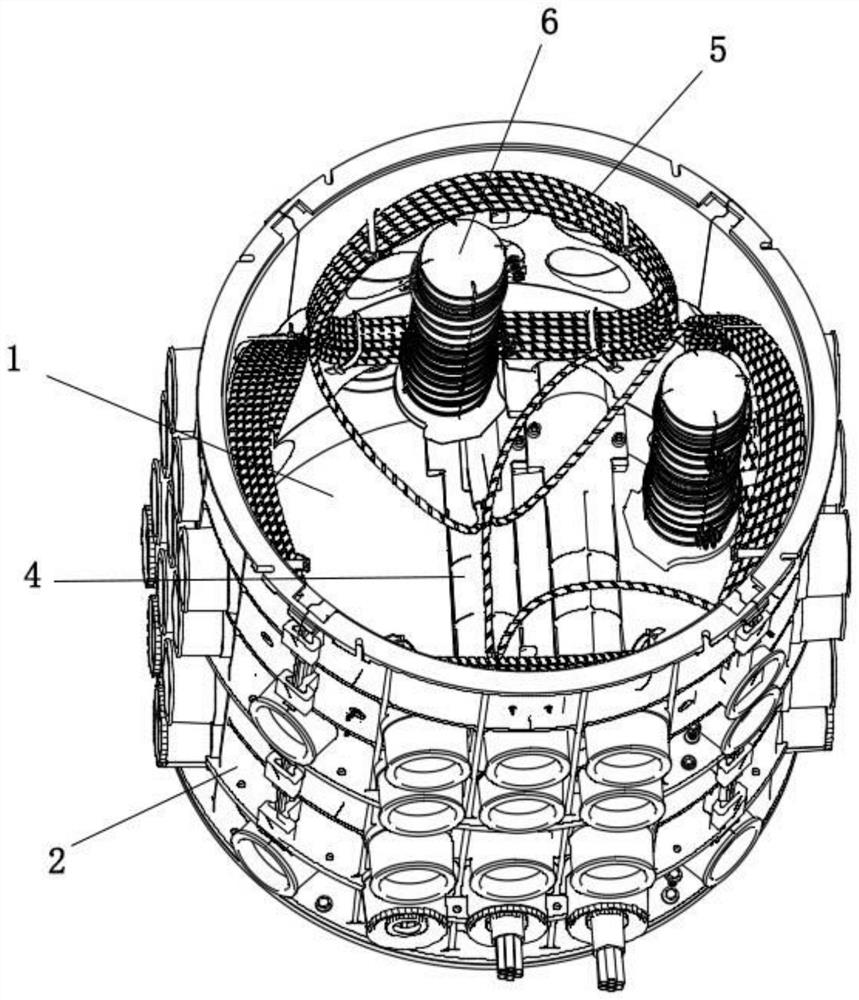

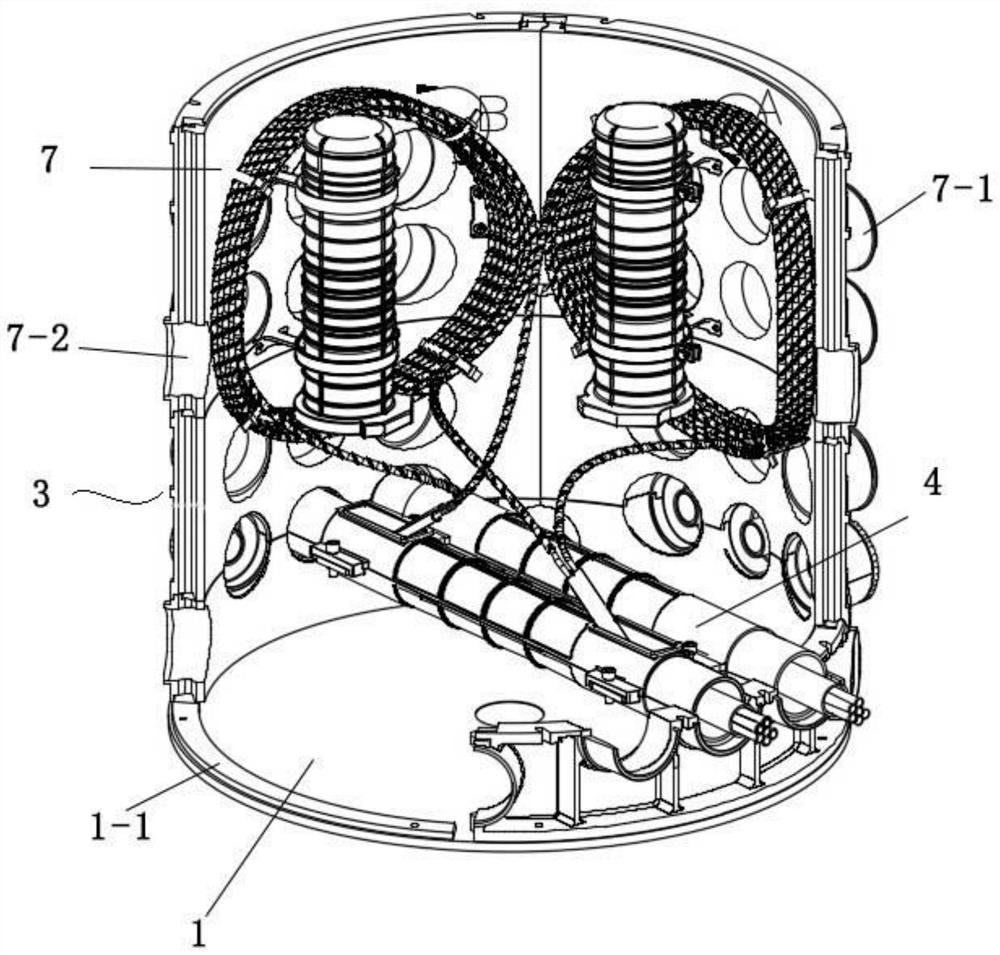

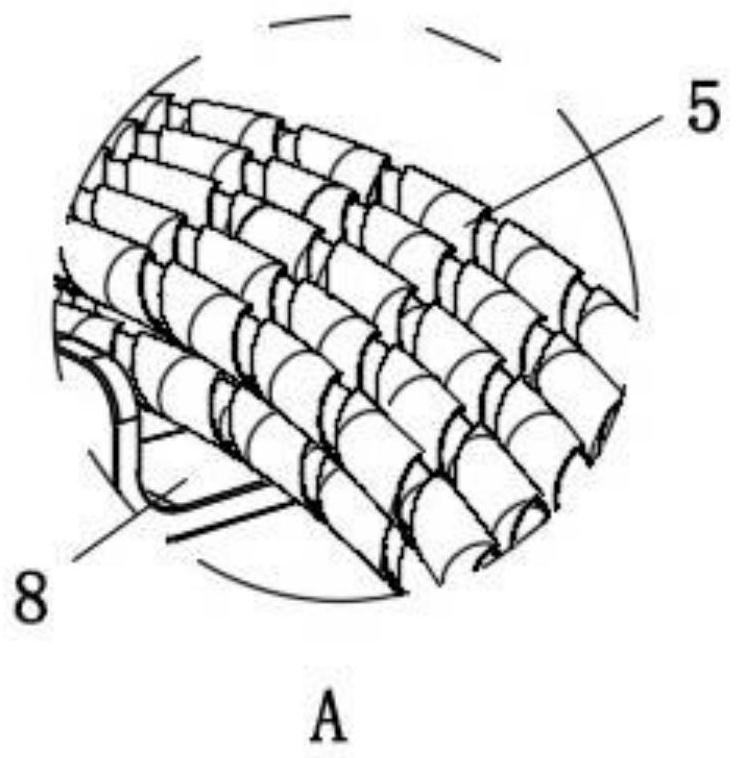

[0030] like Figure 1-12 As shown, a spliced wiring wall 7 for the downhole operation includes a base 1 and a wall assembly 2 on the base 1, and the wall assembly 2 is stacked by at least one frame structure 3, a frame structure. 3 is spliced from a plurality of wall plates 7; the outer wall of the wall plate 7 is provided with a sleeve 7-1 in which the interior of the frame structure 3 is connected, and the sleeve 7-1 is provided with a first cover 7-9 or With the standing seat; the arc groove 7-2 is formed on both sides of the wall plate 7, and the arc grooves 7-2 of the adjacent wall plate 7 are connected, and the arc groove 7-2 is provided with a second cover 7-12. The frame forming structure 3 is provided with a guard cable 4, and both ends of the guard cable are in communication with the fitting seat, and the guard cable 4 consists of a detachab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com