Dairy product mixing device capable of avoiding condensed milk residues

A technology for mixing devices and dairy products, applied in mixers, mixers with rotary stirring devices, dissolving and other directions, can solve the problems that condensed milk cannot be mixed and stirred, wasted, washed and discarded, and cannot be exported, and achieves efficient condensed milk agitation processing. , the effect of efficient discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art are in the range of the present invention without making creative labor premise.

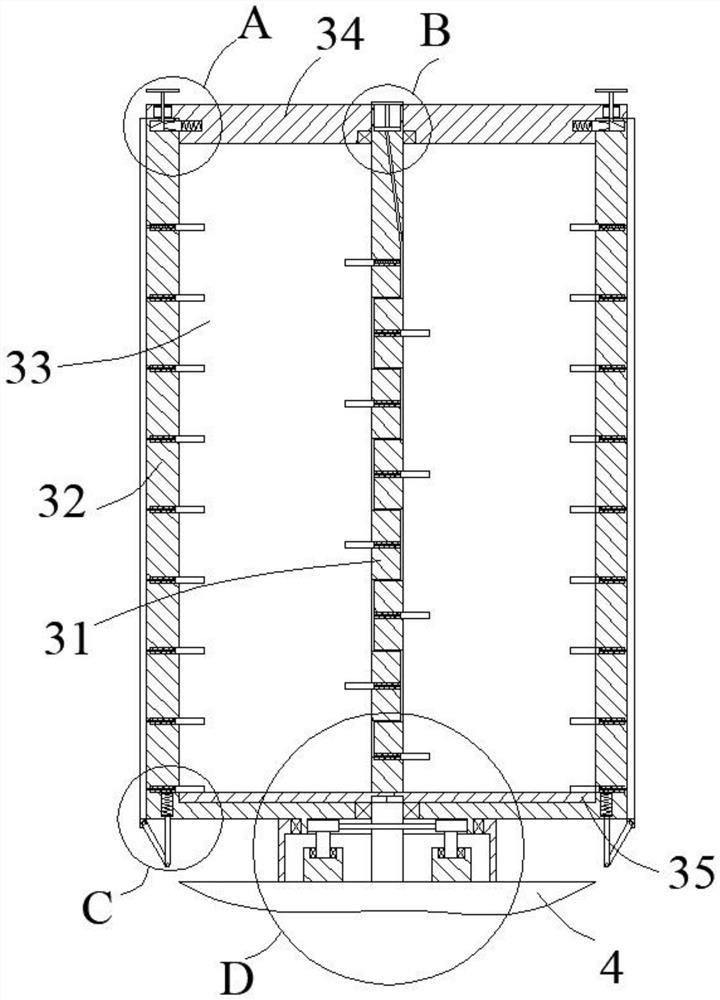

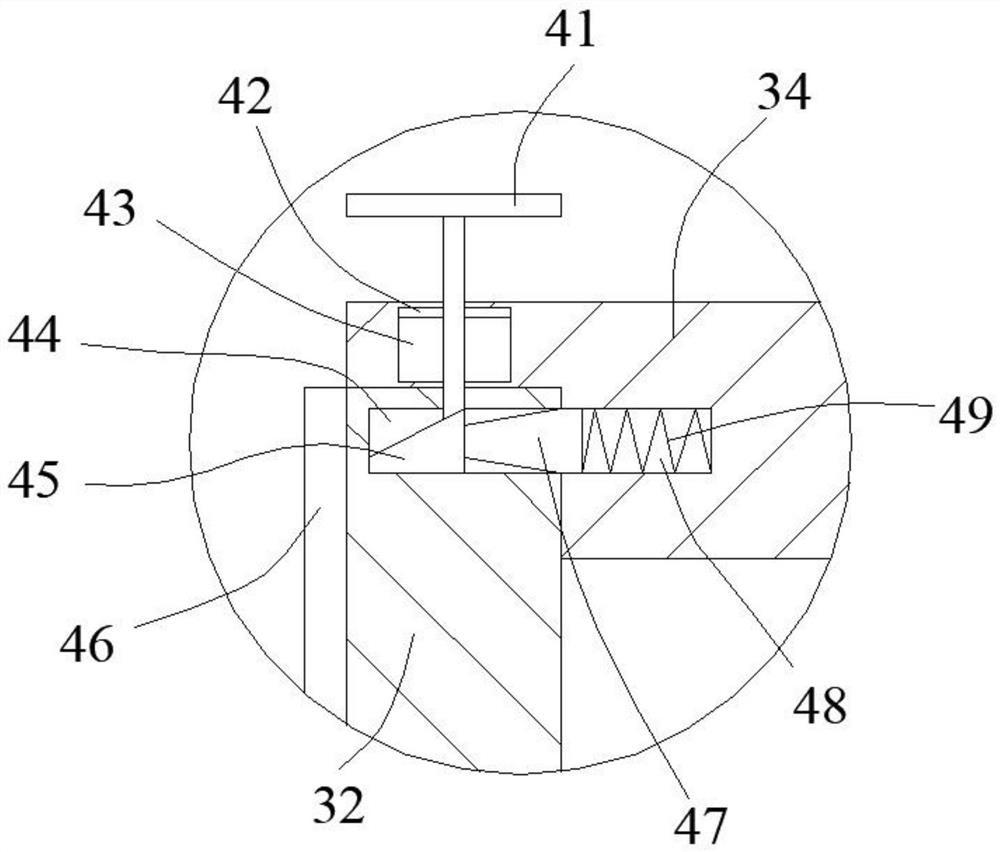

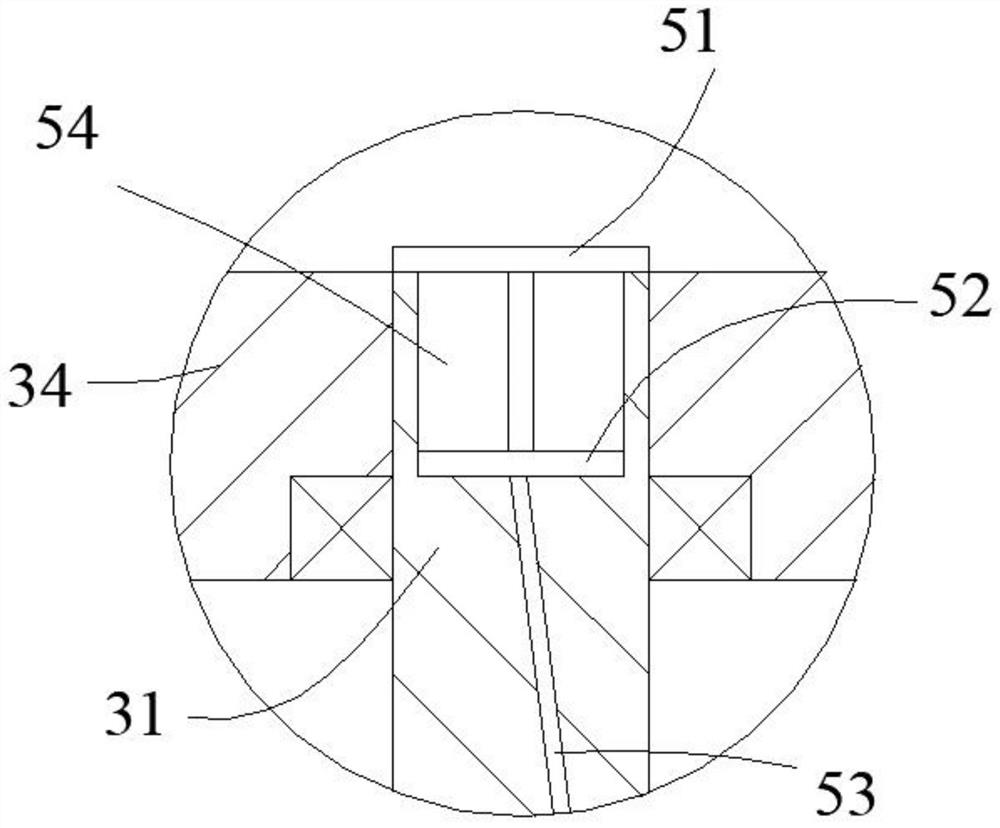

[0024] See Figure 1-5 The present invention provides a residual anti condensed milk dairy mixing apparatus aspect: the structure includes an outer housing 32, outer housing 32 is provided with internal cavity 33, an end wall 33 of the slide chamber 68 is provided with a plurality of the stirring rod , the stirring rod 68 by the resilient means slidably disposed within the outer housing 32 of the drive slide 68 so that the stirring rod can extend in use can be retracted into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com