Dismounting device for airplane wire harness pipe joint

A technology for dismantling devices and pipe joints, which is applied to workpiece clamping devices, manufacturing tools, hand-held tools, etc., can solve the problems of high maintenance costs and difficult disassembly of metal snap rings, and achieve reliable and durable quality, good adaptability, Easy to control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

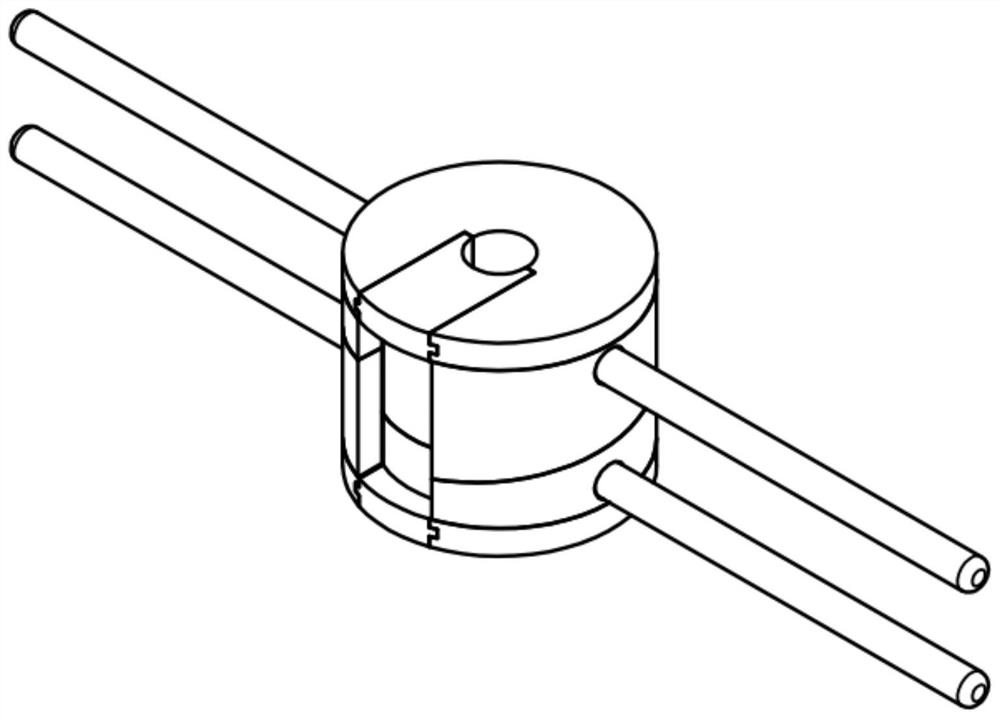

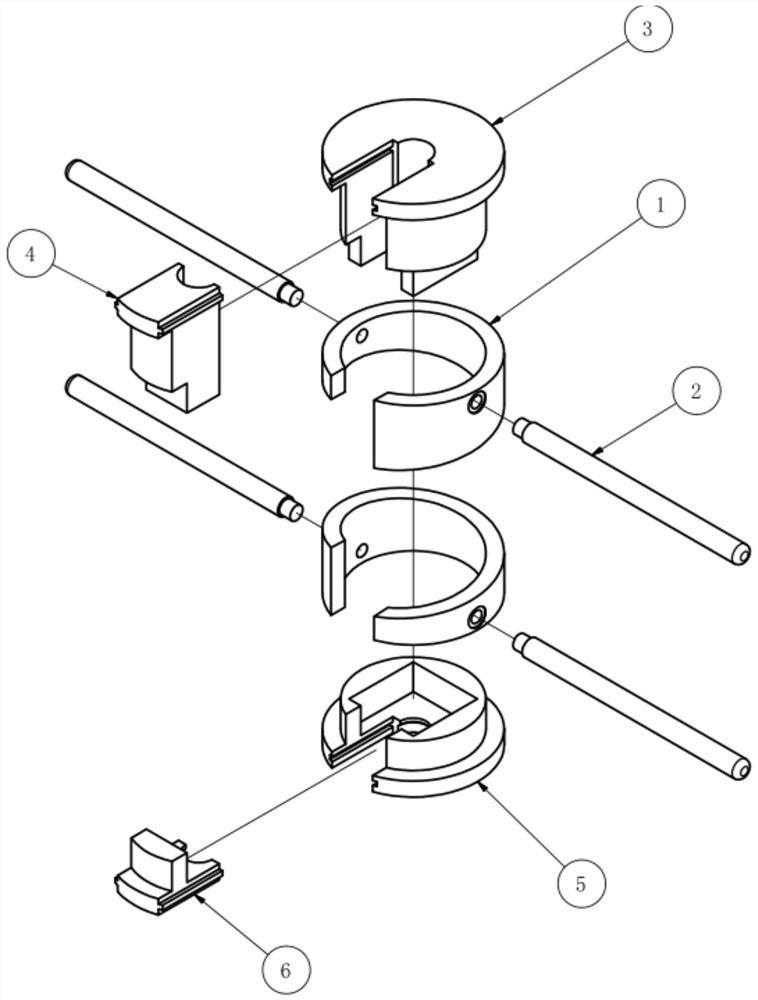

[0049] Referring to the accompanying drawings, the embodiment of the dismantling device for the aircraft wire harness pipe joint of the present invention includes:

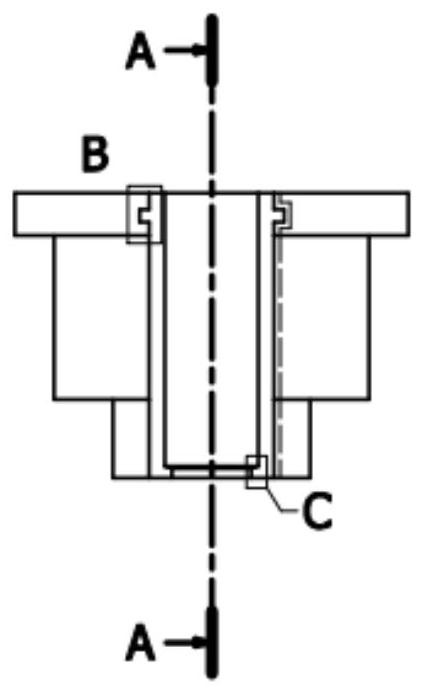

[0050] An upper fixture 3 is a coaxial two-step stepped cylinder with upper, lower, and lower dimensions. The top is a flat cylinder, the middle is a cylinder, and the bottom is a square column. There is a through hole in the center of the cylinder with upper, lower, and small steps. There is a notch through the upper and lower bottom surfaces and directly to the through hole, the two sides of the notch are parallel, and there are corresponding horizontal grooves on the two sides of the notch of the cylinder body of the flat cylinder; with an upper plug 4, the shape corresponds to the column There is a body gap, and a protruding edge is provided on the two sides corresponding to the horizontal groove position of the cylinder gap, so that the upper plug 4 can be inserted and pulled out of the cylinder gap from the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com