Railway wheel with small deformation

A technology for railway vehicles and railways, which is applied in the direction of wheels, wheels characterized by track running parts, and vehicle parts, etc. It can solve the problem that the thermal conductivity of composite materials is not as good as that of metal, increase the deformation of railway wheels, and increase the residual tensile stress of railway wheels And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

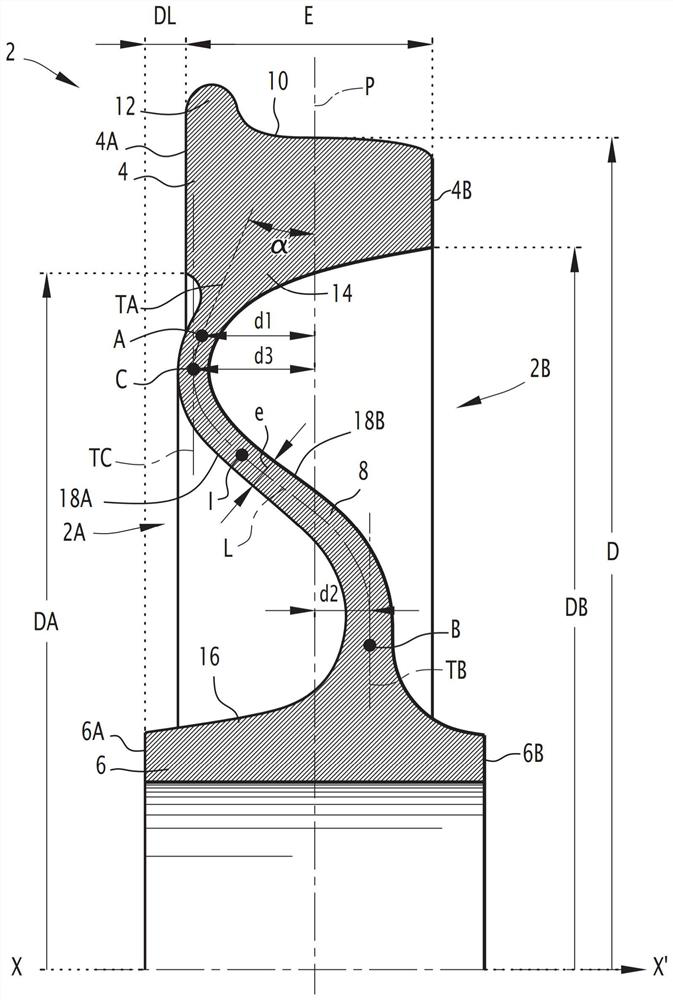

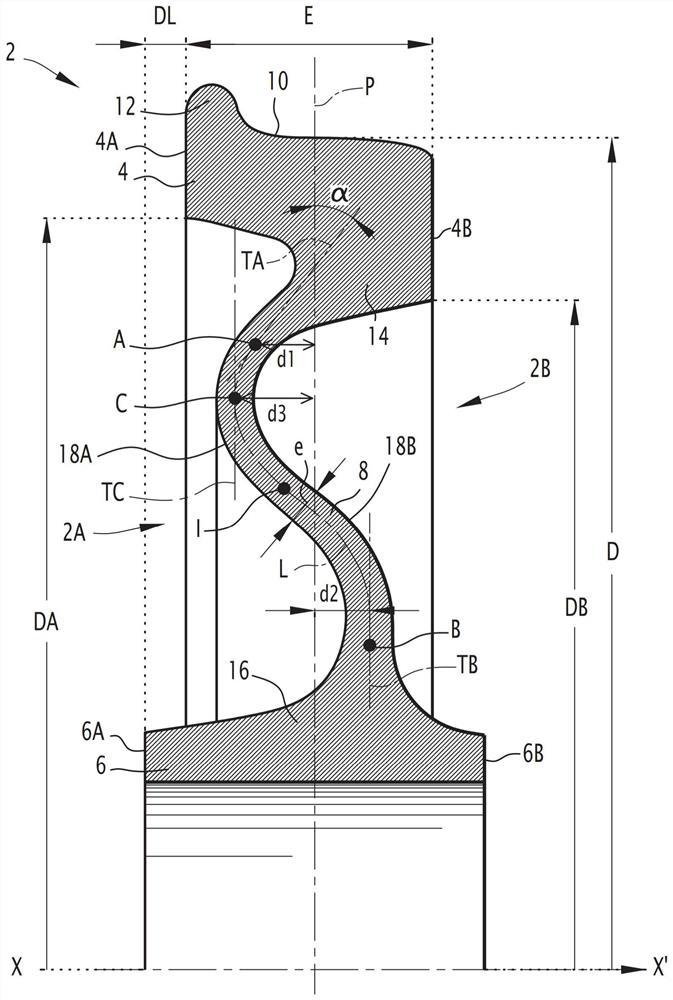

[0032] figure 1 The railway wheel 2 shown has a general shape of revolution about a central axis X-X', the railway wheel having a rim 4, a hub 6 and a web 8 ensuring the connection between the rim 4 and the hub 6.

[0033] Preferably, the railway wheel 2 is implemented as a single piece of material. Thus, the rim 4, the hub 6 and the web 8 are made in one piece. The railway wheel 2 is eg forged or molded.

[0034] The railway wheel 2 has two opposing surfaces, a first surface 2A and a second surface 2B.

[0035] The first surface 2A is arranged towards another railway wheel coaxial with the railway wheel 2 and forms an axle therewith, and the second surface 2B is arranged towards the opposite direction to said other railway wheel.

[0036] The rim 4 has a wheel tread 10 and a rim 12 .

[0037] The wheel tread 10 is the surface of the rim 4 over which the rim 4 rolls on the railway track during operation.

[0038] The rim 12 is located on one edge of the rim 4 and on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com