Method and system for calibrating and adjusting heliostat

A technology for calibration and adjustment of heliostats, applied in the direction of use feedback control, etc., can solve the problems that the tracking effect of heliostats does not give a monitoring method, and the reflection of heliostats cannot be monitored, etc., to achieve outstanding substantive features and design principles Reliable, Simple Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

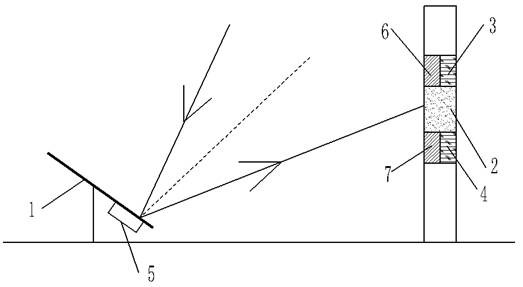

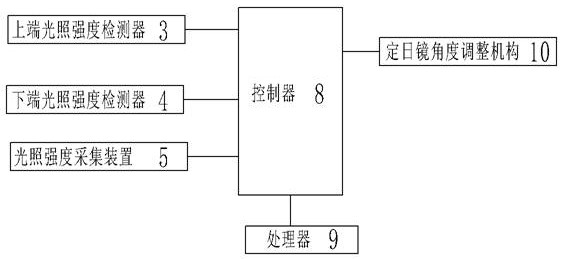

[0041] Such as figure 1 and 2 As shown, the calibration and adjustment system of a heliostat provided in this embodiment includes:

[0042] Actively adjust the angle of the heliostat module, which actively adjusts the angle of the heliostat 1 according to the angle of sunlight, first obtains the incident angle of the sun’s rays relative to the ground, which is denoted as A; then obtains the light emitted by the heliostat 1 The incident angle of the collector relative to the ground is denoted as B; finally adjust the angle of the heliostat relative to the ground, denoted as C;

[0043] Among them, C=90°-(0.5*A+0.5B);

[0044] Modified Adjust Heliostat Angle module, which includes:

[0045] The upper light intensity detector 3 located above the heat collector 2, the lower light intensity detector 4 located below the heat collector 2, the light intensity collection device 5 located on the heliostat, and the upper reflector is also arranged above the heat collector 6. There is...

Embodiment 2

[0051] This embodiment also provides a method for calibrating and adjusting a heliostat, including the following steps:

[0052] Step S1: a step of actively adjusting the angle of the heliostat according to the angle of sunlight, which includes the following steps:

[0053] S11: Obtain the incident angle of the sun's rays relative to the ground, denoted as A;

[0054] S12: Obtain the incidence angle of the light emitted by the heliostat to the collector relative to the ground, denoted as B;

[0055] S13: Adjust the angle of the heliostat relative to the ground, denoted as C;

[0056] Among them, C=90°-(0.5*A+0.5B);

[0057] Step S2: a step of correcting and adjusting the angle of the heliostat, which includes the following steps:

[0058] S21: Obtain the detection intensity of the upper end of the light above the heat collector, and the detection intensity of the lower end of light below the heat collector;

[0059] S22: If the change value of the light intensity of the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com