Electric meter fault frequency prediction method and system

A technology of failure times and forecasting methods, applied in forecasting, information technology support systems, data processing applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

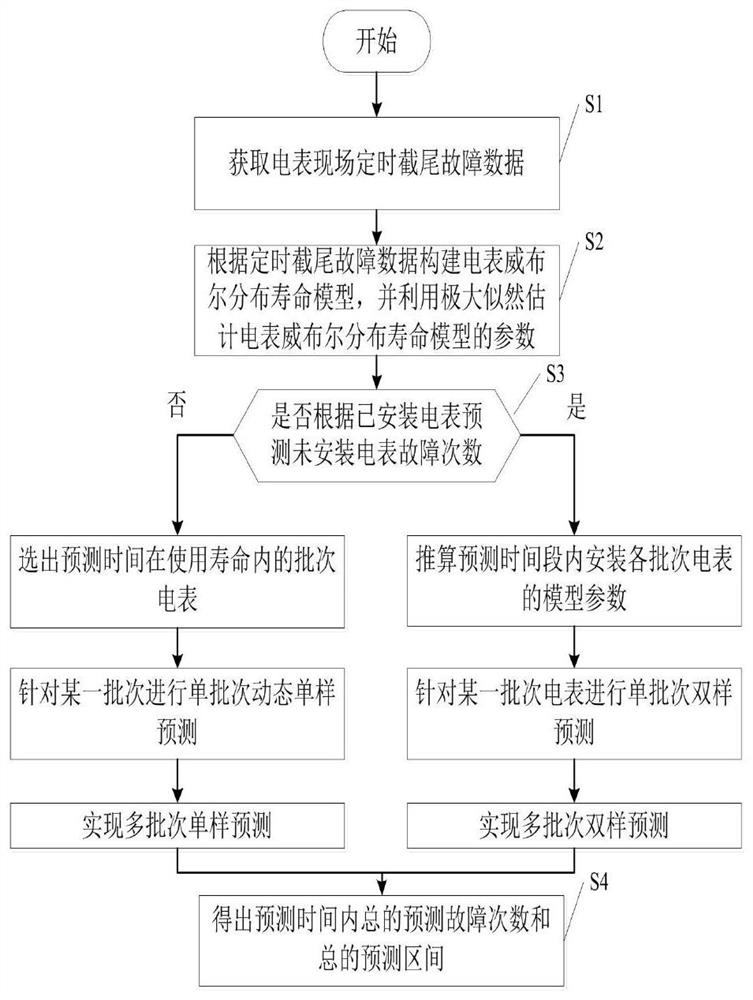

[0039] Based on the above explanation, see figure 1 , the invention provides a method for predicting the number of electric meter faults, the prediction method comprising:

[0040] S1: Acquire on-site timed censored fault data of electric meters; the timed censored fault data includes the installation time of each batch of electric meters, the number of installed electric meters of each batch, the observation time, the number of electric meter failures within the observation time, and the predicted time The time corresponding to the failure of each electric meter, wherein the start time of the predicted time is the end time of the observation time;

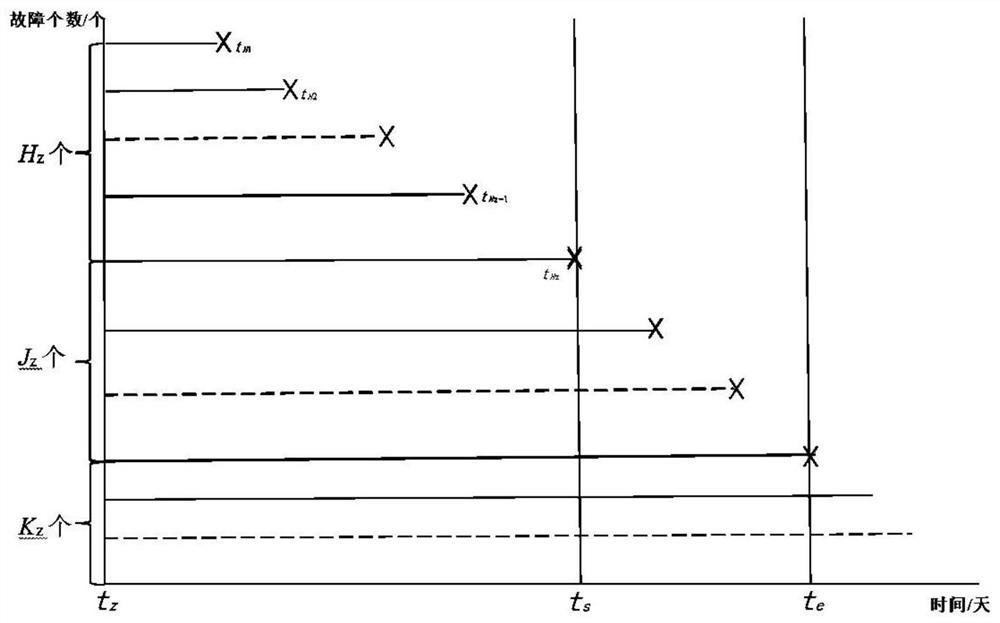

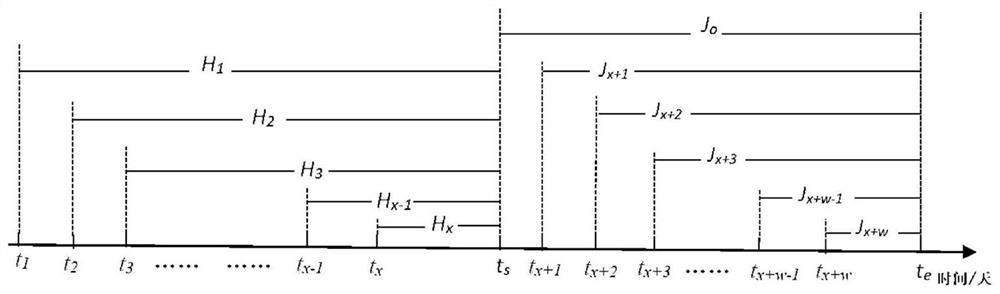

[0041] In practical applications, such as figure 2 As shown, assuming a batch of meters at time t z sometimes N z Taipower meter put into use, at the observation time (t z ,t s ] with H inside z A meter fails, and the time when each meter fails is recorded as t H1 , t H2 ,...,t Hz , if a given prediction time t s , t e...

Embodiment 2

[0135] see Figure 4 , the present invention also provides a prediction system for the number of electric meter failures, the prediction system comprising:

[0136] Timing censoring fault data acquisition unit 1, used to obtain the timing censoring fault data of the electric meter field; the timing censoring fault data includes the installation time of each batch of ammeters, the installation number of each batch of ammeters, the observation time, the observation time The number of failures of the internal electric meters, the predicted time and the corresponding time when each electric meter fails, wherein the start time of the prediction time is the end time of the observation time;

[0137] The life model construction unit 2 is used to construct the Weibull distribution life model of the electric meter according to the timing censored fault data, and utilize the maximum likelihood to estimate the parameters of the Weibull distribution life model of the electric meter;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com