A kind of rockfill concrete masonry structure and construction method thereof

A technology of rockfill concrete and masonry structure, which is applied in sea area engineering, water conservancy engineering, construction, etc., and can solve the problem of uneven surface of rockfill concrete masonry layer, irregular shape of rockfill, difficulty in reaching the gap between rockfill and formwork, etc. problems, to achieve the effect of enhancing internal stability, enhancing stability, and improving structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

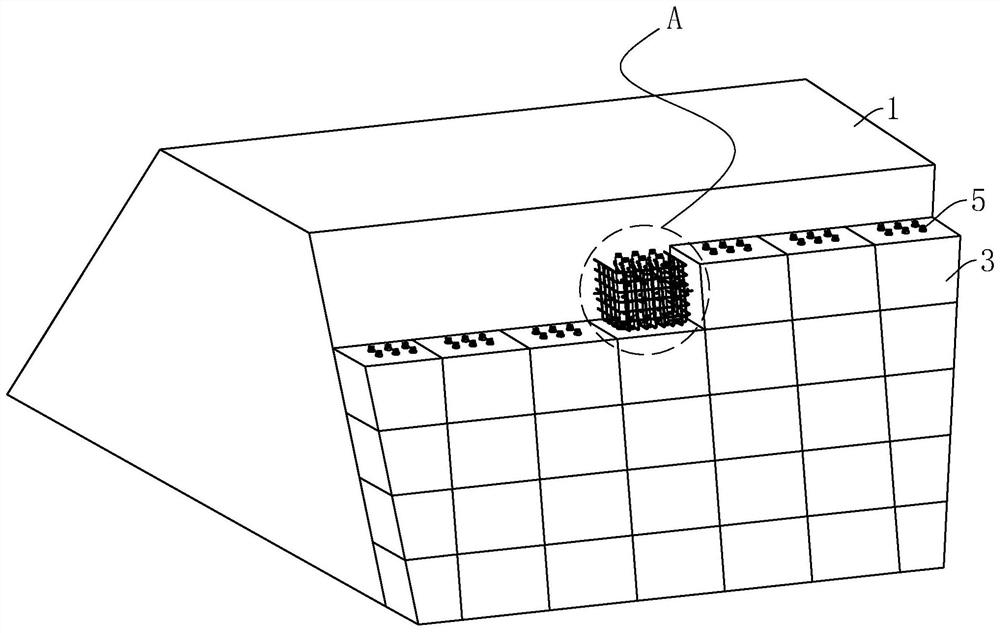

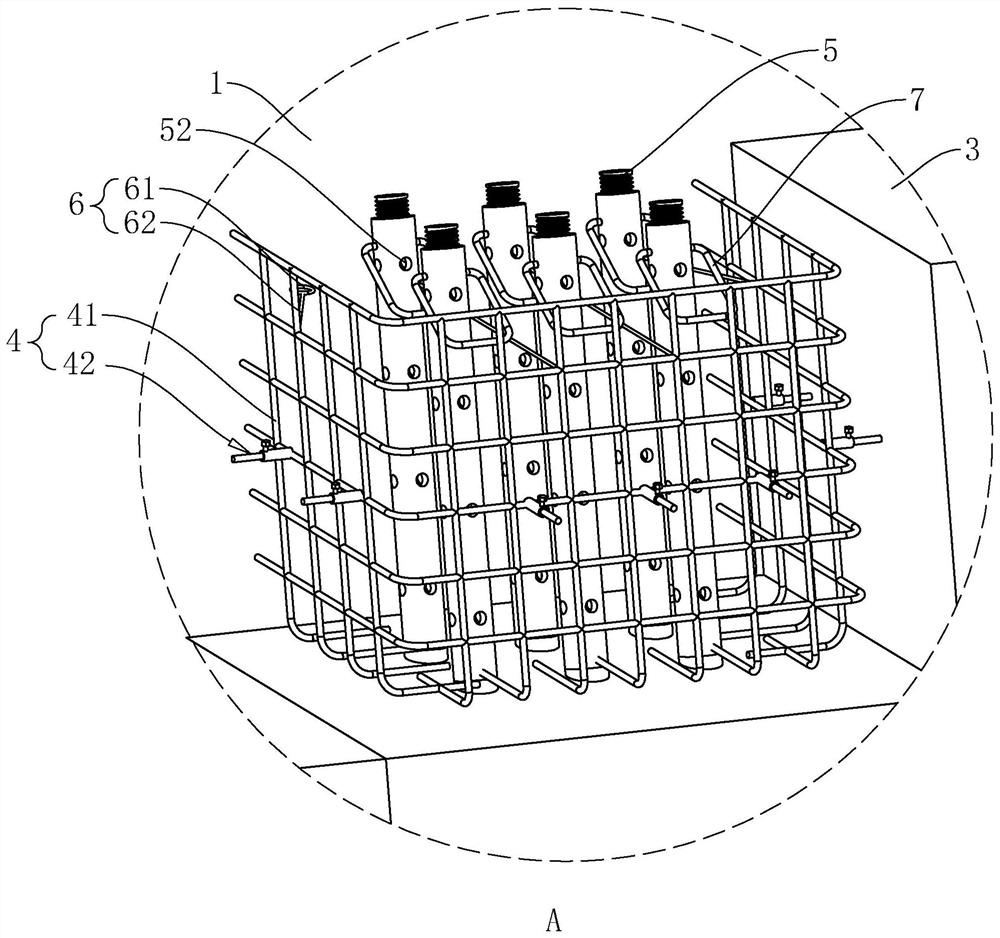

[0038] Attached to the following Figure 1-4 The present invention will be described in further detail.

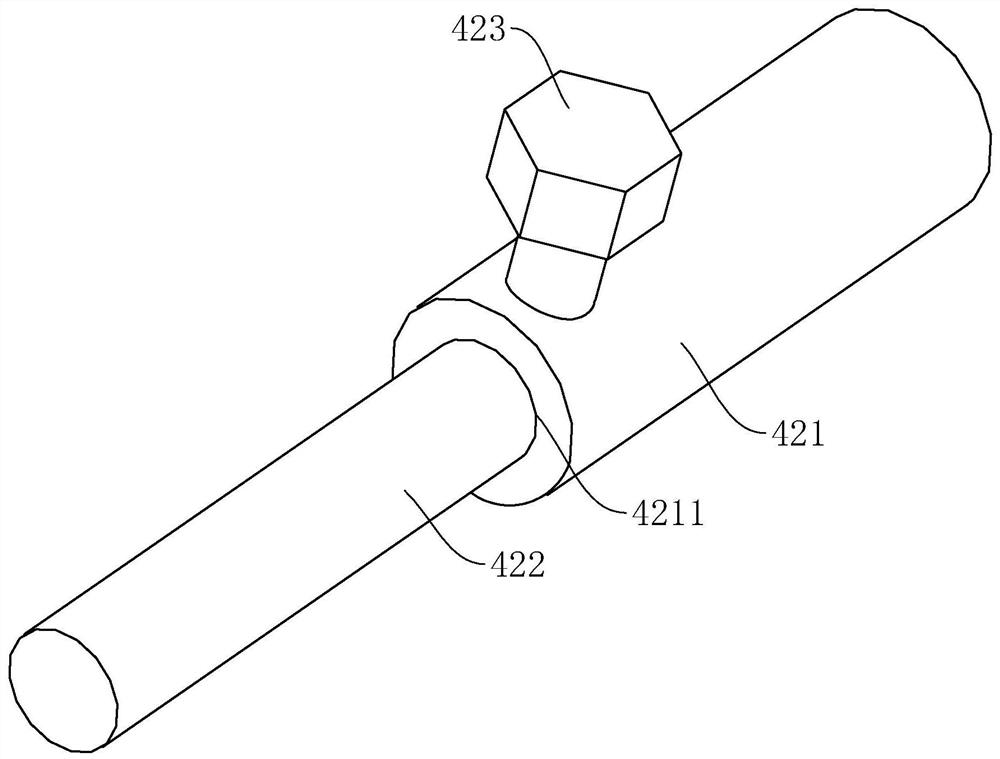

[0039] A rockfill concrete masonry structure disclosed in the embodiments of the present application, such as figure 1 , 2 As shown in the figure, including several rock-fill concrete units built on the side of the dam body 1, several rock-fill concrete units on each side of the dam body 1 are arranged in turn in the vertical and horizontal directions. On the construction site, the layers are layered from top to bottom. Carry out construction. The rockfill concrete unit includes a rockfill layer (not shown in the figure) stacked on one side of the dam body 1, a concrete layer 3 wrapped around the rockfill layer, and a connecting component 4 wrapped inside the concrete layer 3, and the connecting component 4 is used for supporting There is always a gap between the rockfill layer and the formwork, and between the rockfill layer and the formwork on the side away from the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com