Control method and control system of servo electric screwdriver

A control method and servo electric technology, applied in the field of servo electric batches, can solve the problems of no feedback resistance, screwing quality problems, inability to accurately reflect the screwing process of servo electric batches, etc., and achieve the effect of improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to clearly and completely understand the technical solution, the present invention will be further described in conjunction with the embodiments and accompanying drawings. Obviously, the recorded embodiments are only part of the embodiments of the present invention. All other obtained embodiments belong to the protection scope of the present invention.

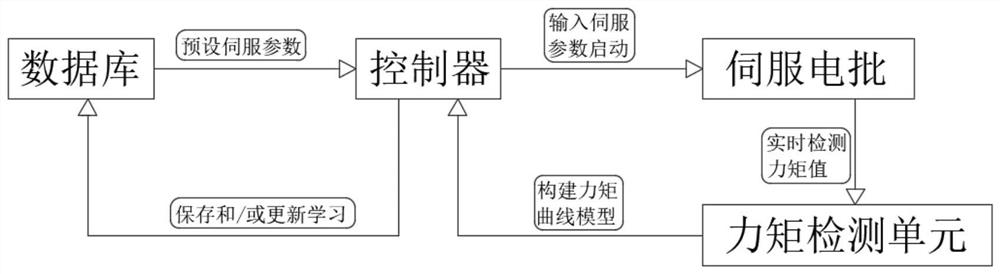

[0026] Such as figure 1 As shown, a control method of a servo electric batch includes:

[0027] Configure the preset servo parameters of the servo electric batch, and the preset servo parameters are obtained from the database;

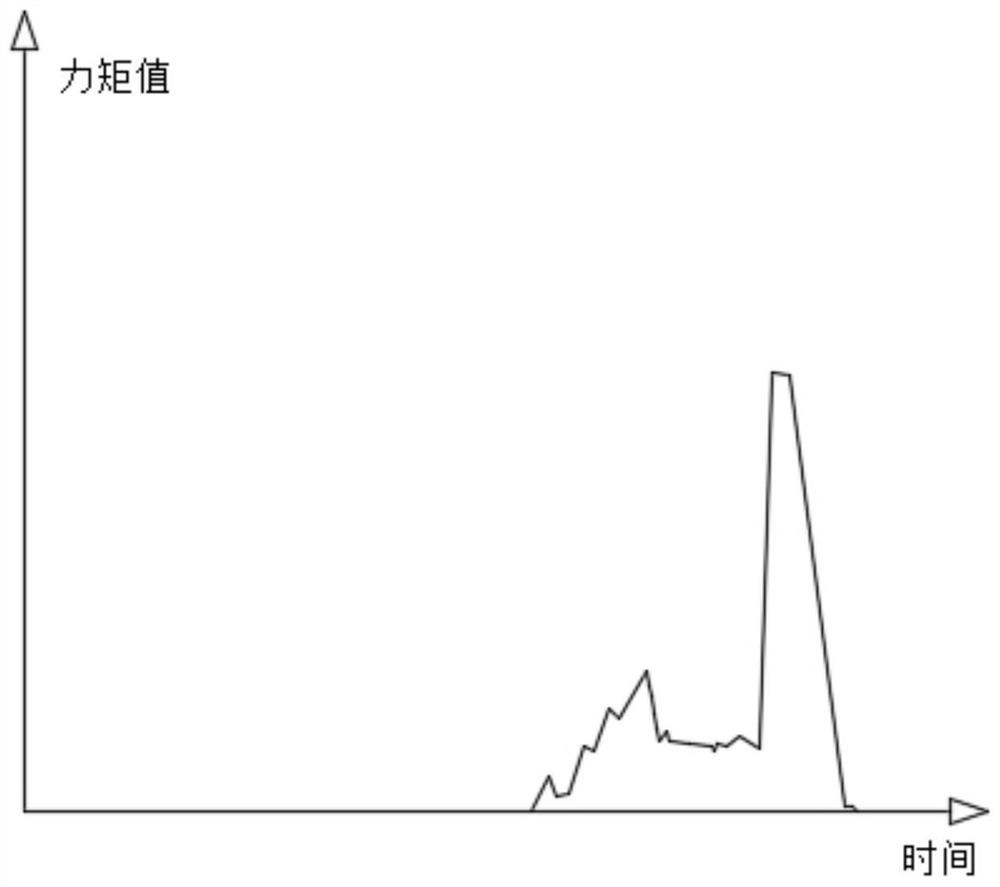

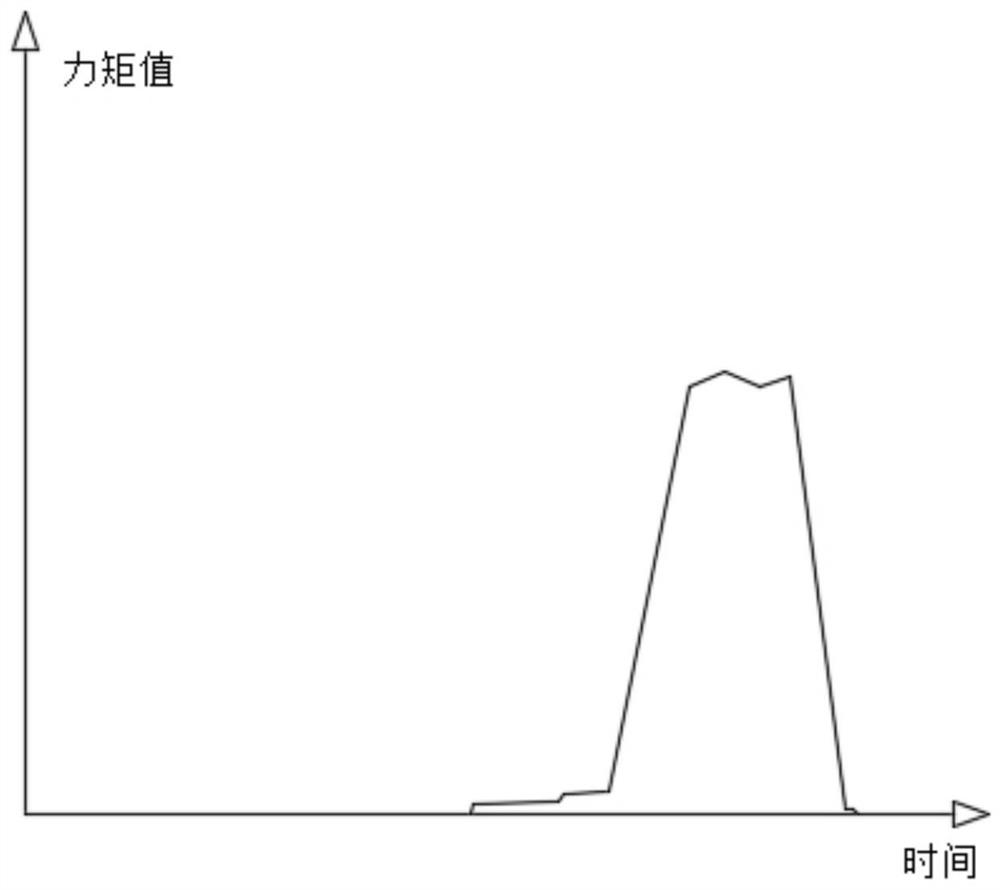

[0028] Start the controller to input preset servo parameters to make the servo electric batch run and detect the torque value through real-time torque to build a torque curve model;

[0029] Judging whether the torque value of the torque curve model exceeds a preset range at a preset time to obtain a judgment result, wherein the judgment result includes at least one of the following: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com