Label printer

A technology for printers and labels, applied in typewriters, printing devices, printing, etc., to improve the success rate of paper return, simplify operations, and improve user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

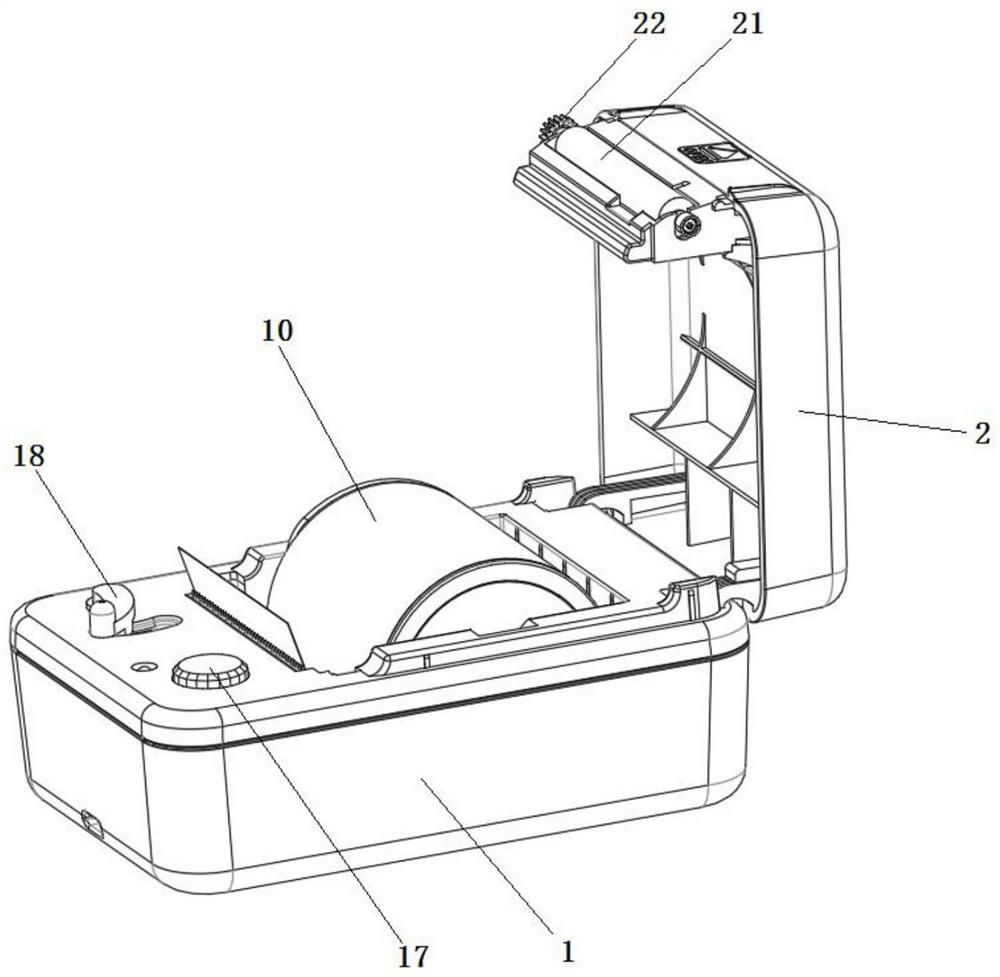

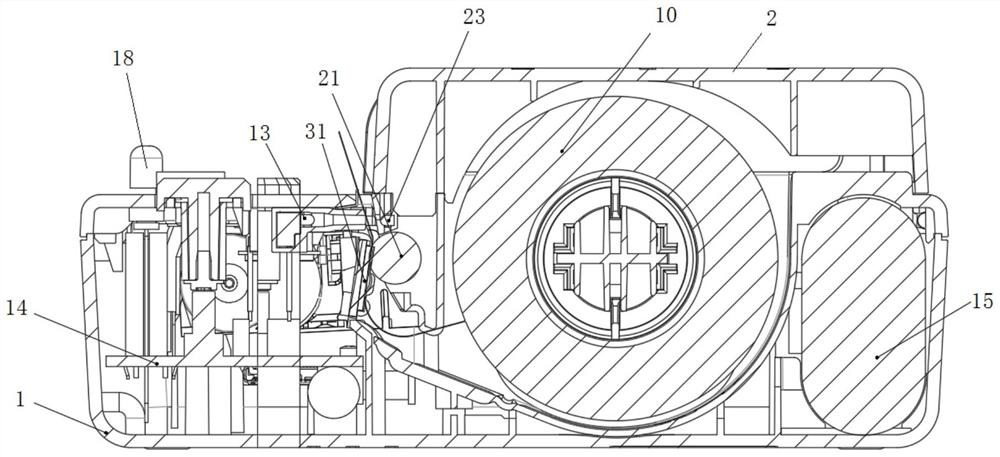

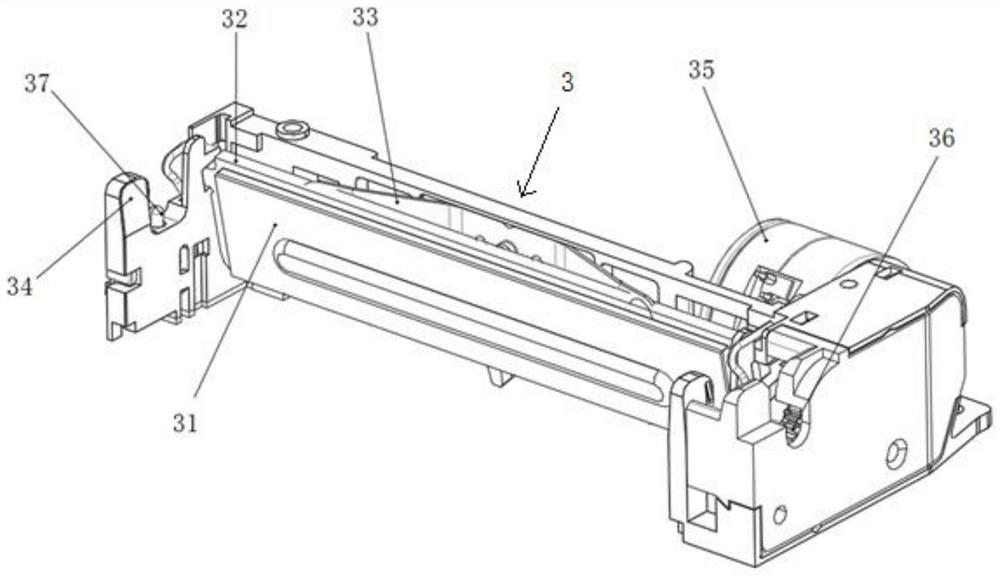

[0037] Refer to attached figure 1 and 2 As shown, the label printer in this embodiment includes a housing 1 and a cover 2 rotatably connected to the housing 1 . The housing 1 includes a label roll installation mechanism, an electric power mechanism and a print head assembly 3 . The cover 2 is provided with a rubber roller 21, and when the cover 2 is fastened on the housing 1, the rubber roller 21 is connected with the electric power mechanism, and the rubber roller 21 is connected with the The print head ceramic plate 31 of the print head assembly 3 is arranged oppositely, the label paper passes between the rubber roller 21 and the print head ceramic plate 31, and the rubber roller 21 realizes forward and reverse rotation under the action of the electric power mechanism, Complete the ejection and ejection of label paper.

[0038] In this embodiment, the housing 1 is formed by fastening the upper housing and the lower housing, forming a cavity for placing the label roll 10, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com