Slope foundation compaction machine

A technology for slope surface and foundation, which is applied in basic structure engineering, construction, soil protection, etc., can solve problems such as uneven settlement, difficult construction quality control, slope landslide, etc., and achieves low cost and the effect of eliminating settlement and landslide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described in further detail below by embodiment, and embodiment is only used for illustrating the present invention, does not limit the scope of the present invention.

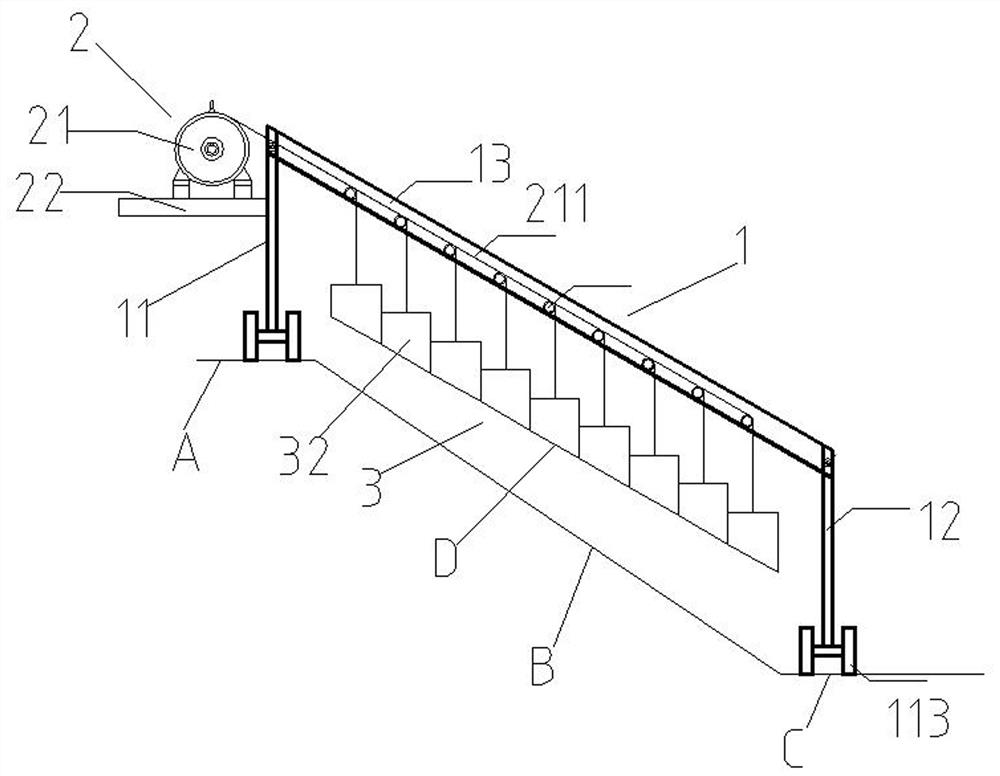

[0016] see Figure 1-2 A slope surface foundation compaction machine shown includes a support system 1, a drive system 2, and a compaction system 3. The support system 1 is used to support the drive system 2 and the compaction system 3. The drive system 2 drives the compaction system 3 to move ,

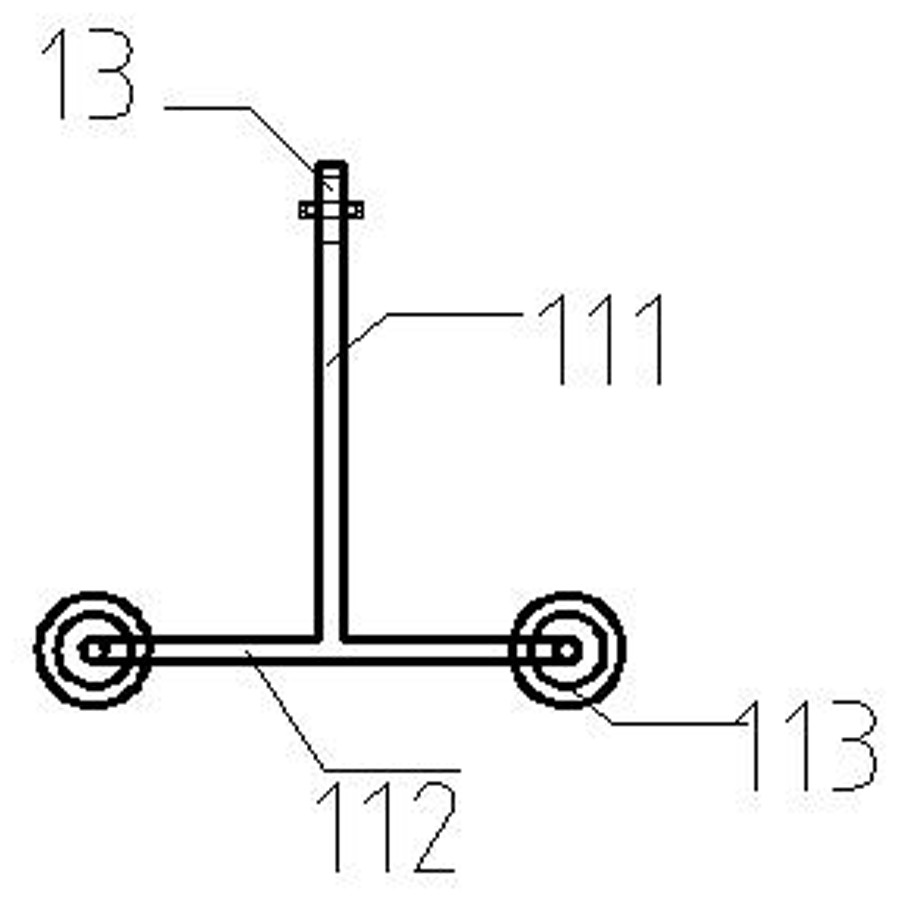

[0017] The support system 1 includes an upper support trolley 11, a lower support trolley 12 and a support beam 13, the upper support trolley 11 is located on the upper plane A, the lower support trolley 12 is located on the lower plane C, and the upper plane A is located on the upper side of the lower plane C A slope B is set between the upper plane A and the lower plane C, a support beam 13 is set between the upper support trolley 11 and the lower support trolley 12, the support bea...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap