Battery, battery outgoing line method and electronic device

A technology of batteries and batteries, which is applied in the field of battery outlets, electronic devices, and batteries, and can solve problems such as circuit board damage, lack of mobility, and impact on batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

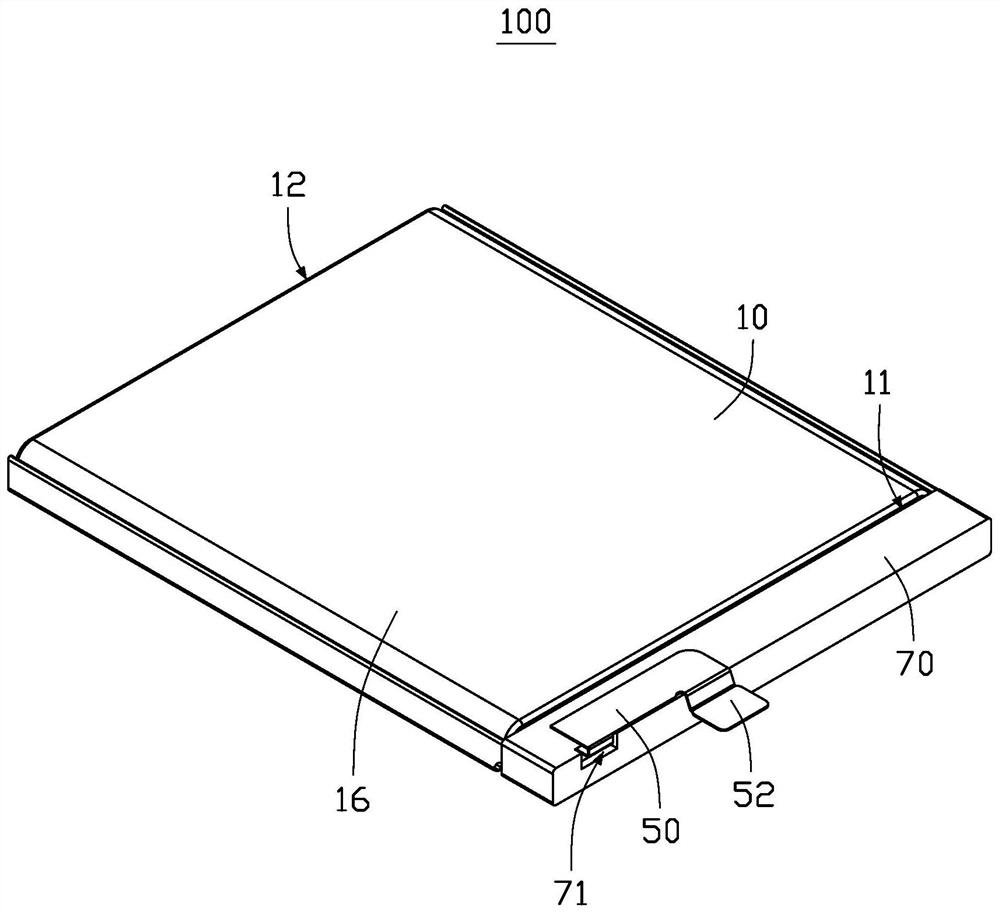

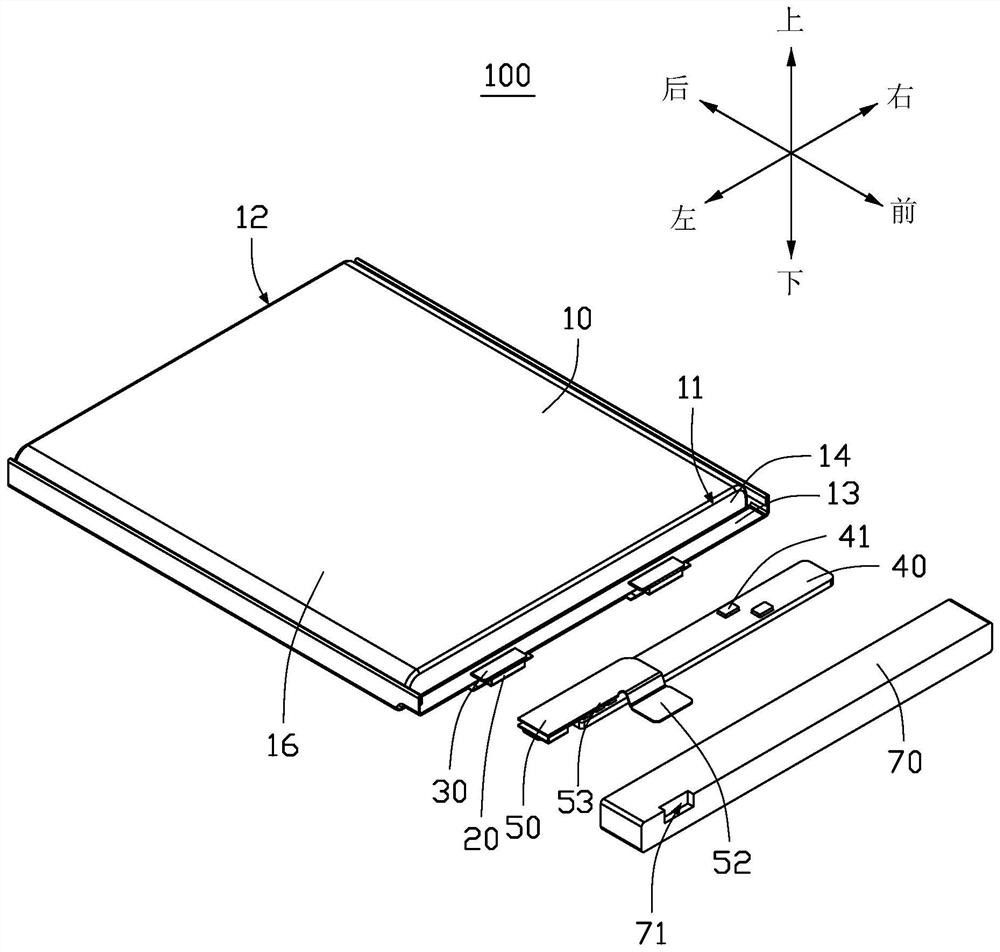

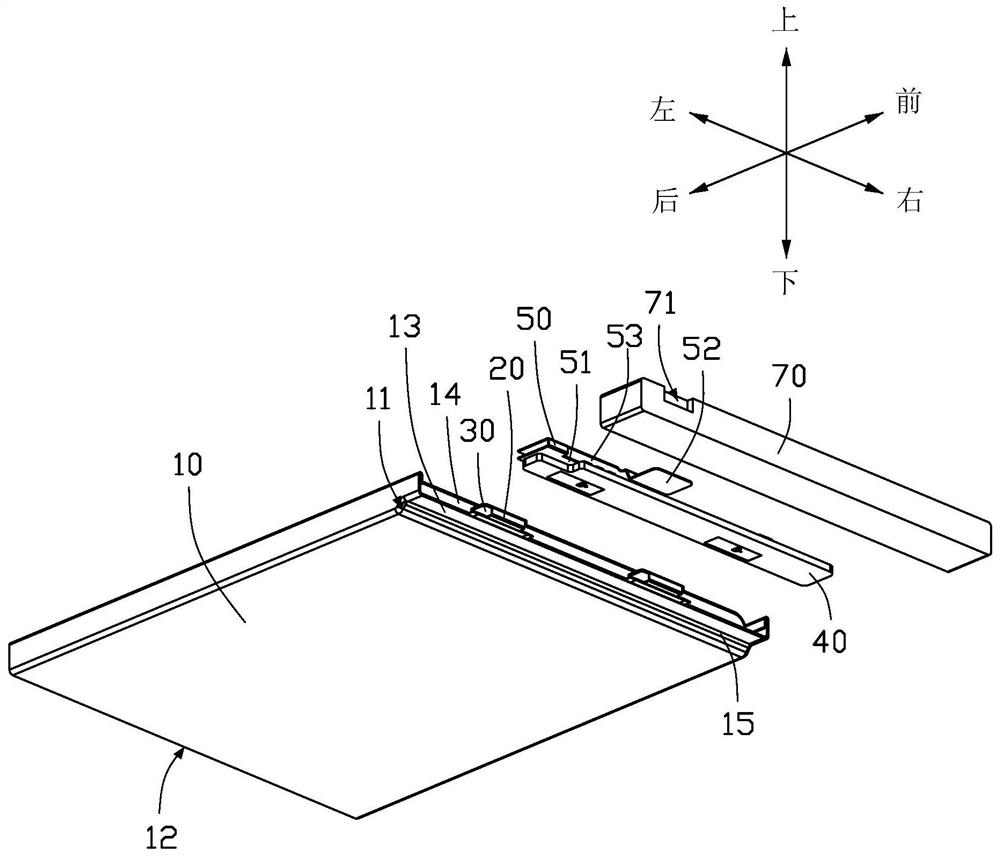

[0068] see figure 1 and figure 2 , providing a battery 100 for providing electric energy to an electronic device. The battery 100 includes a cell body 10 , a circuit board 40 , a first connector 50 and a gel 70 , and the cell body 10 includes a first side 11 provided with a tab 20 along the length direction and a side 11 away from the tab 20 . 12 of the second side. The circuit board 40 is electrically connected to the tab 20 . The first connecting member 50 includes a first end portion 51, a second end portion 52 and a first bending portion 53 connecting the first end portion 51 and the second end portion 52, the first end portion 51 is electrically connected to the circuit board 40, and the second end 52 is used for connecting external devices. The glue 70 is disposed on the first side 11 and covers the tab 20 , the circuit board 40 and the first end 51 . The first bent portion 53 extends along the surface of the glue 70 , and the second end portion 52 extends out of t...

no. 2 example

[0104] see Figure 5 and Figure 6 , in the second embodiment, the battery 100 is substantially the same as that in the first embodiment, the difference is that the second end portion 52 extends from the first side 11 to a direction close to the second side 12 . When the first connecting member 50 extends toward the second side 12 and passes through the stepped surface formed by the cell body 10 and the glue 70 , the first bent portion 53 is along the stepped surface. It is bent and extends toward the second side 12 along the side wall 16 of the cell body 10 .

[0105] The first connecting member 50 extends out of the cell body 10 from the first side 11 to the second side 12 to connect with external equipment, which can also achieve the same effect as in the first embodiment.

no. 3 example

[0107] see Figure 7 and Figure 8 , in the third embodiment, the battery 100 is substantially the same as that in the first embodiment, the difference is that the battery 100 further includes a second connector 60, and the second connector 60 includes a third end 61, a second The four end portions 62 and the second bending portion 63 connecting the third end portion 61 and the fourth end portion 62 . The third end portion 61 is electrically connected to the circuit board 40 , the second bent portion 63 extends along the surface of the glue 70 , and the fourth end portion 62 is along the length direction of the cell body 10 or The colloid 70 extending in the width direction is connected with external equipment.

[0108] Specifically, the third end 61 is connected to the circuit board 40 , the connection between the third end 61 and the circuit board 40 is the same as the connection between the first end 51 and the circuit board 40 the same way. The second connecting piece ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com