A kind of high elastic composite cable

A composite cable and high-elasticity technology, which is applied in the direction of insulated cables, bendable cables, and cable/conductor manufacturing, can solve the problems that cables cannot withstand overload operation, reduce the service life of cables, and expand and crack cables, so as to improve the use of cables The effect of life and tear resistance, enhanced stretching distance, and improved electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

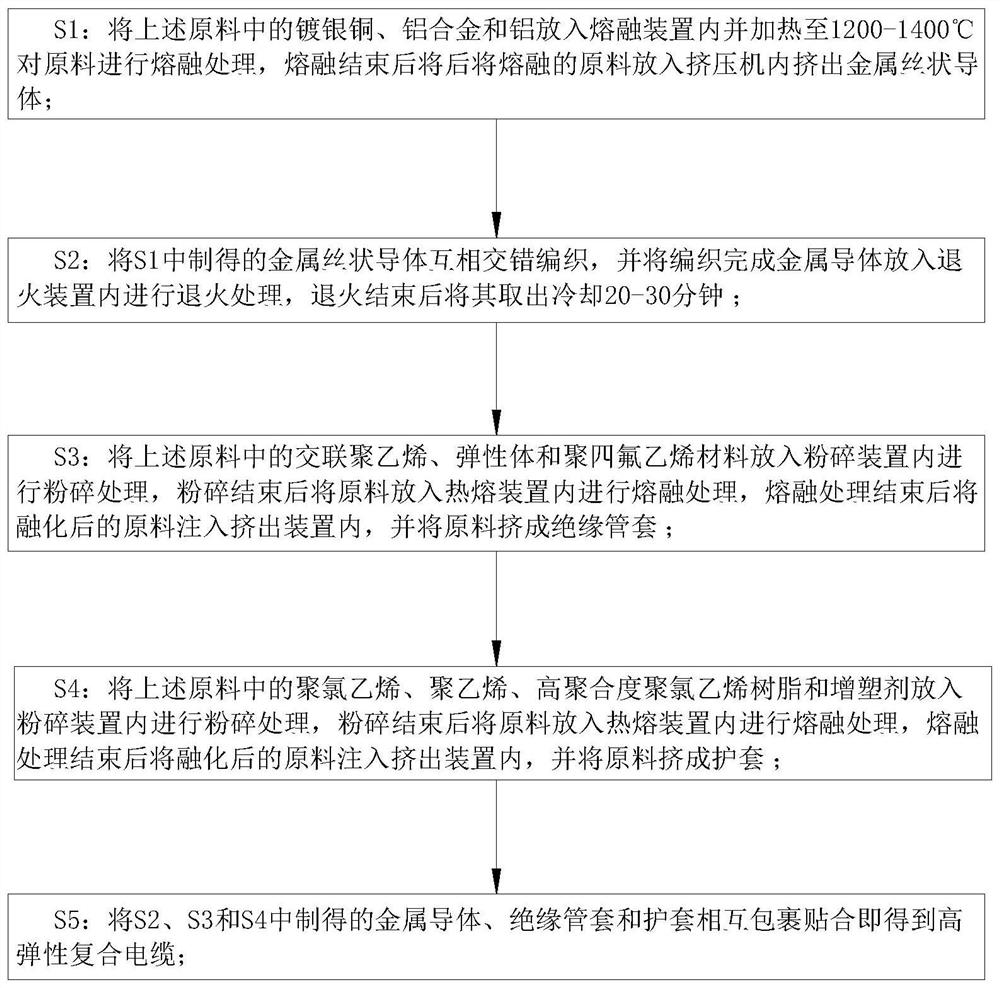

Method used

Image

Examples

Embodiment approach

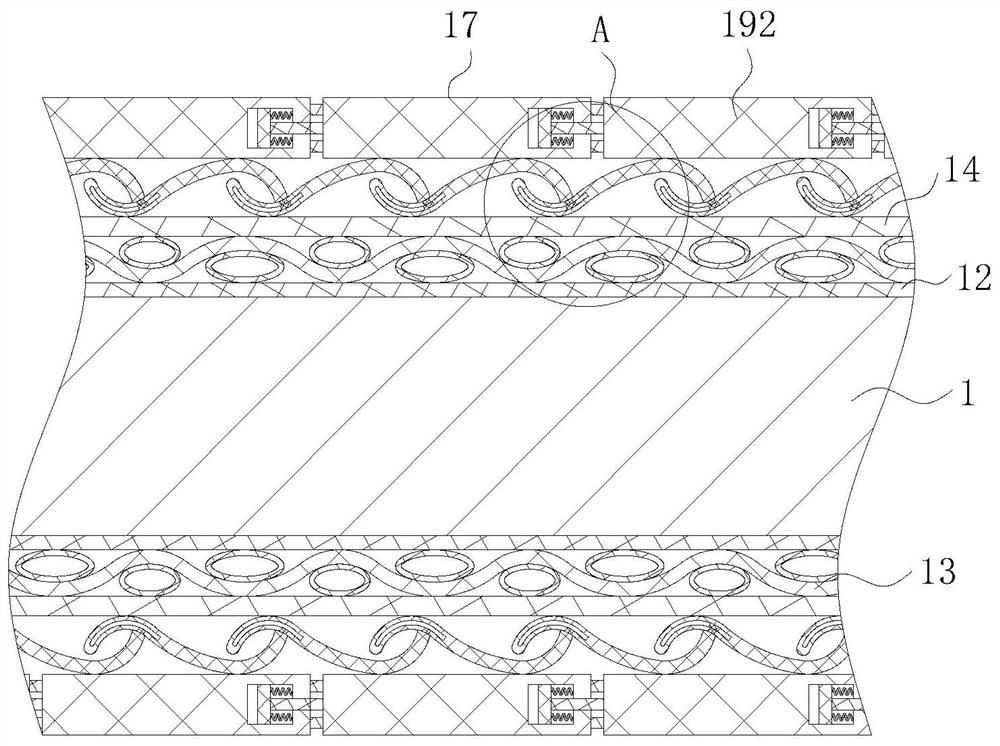

[0035] As an embodiment of the present invention, the elastomer in the raw material is a mixture of styrene-based thermoplastic elastomer and thermoplastic polyester elastomer; the styrene-based thermoplastic elastomer in the elastomer is a kind of Thermoplastic and flexible elastomers also have the characteristics of plastic and rubber. In the present invention, the tensile strength and low temperature resistance of the cable can be improved, and at the same time, it has strong electrical properties, so that the electrical conductivity of the cable can be improved. It can improve the elasticity and wear resistance of the cable. The thermoplastic polyester elastomer in the elastomer is an elastomer with high strength and high elasticity. In the present invention, the flexibility and dynamics of the cable can be improved by mixing with other raw materials. Mechanical properties, while also improving the service life and tear resistance of the cable, as the thermoplastic polyeste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com