Combined hydraulic cylinder with floating cylinder body

A combined, hydraulic cylinder technology, applied in the hydraulic field, can solve the problems of large pulling force, destructiveness, and damaged conduits, and achieve the effects of alleviating the pulling force, not easy to crack, and easy to repair and replace.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

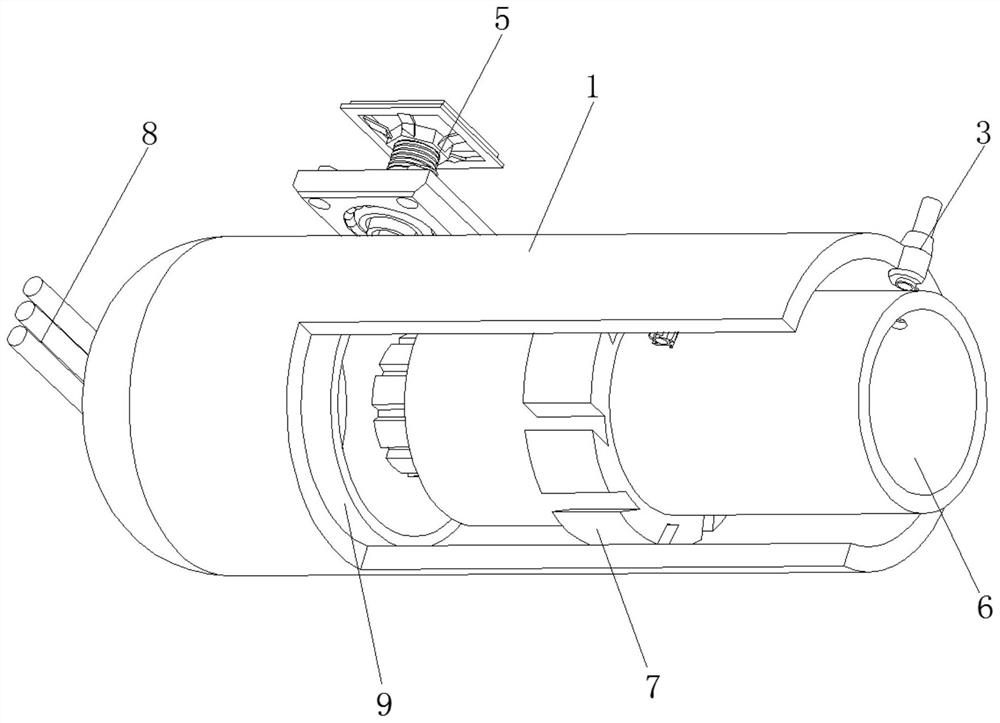

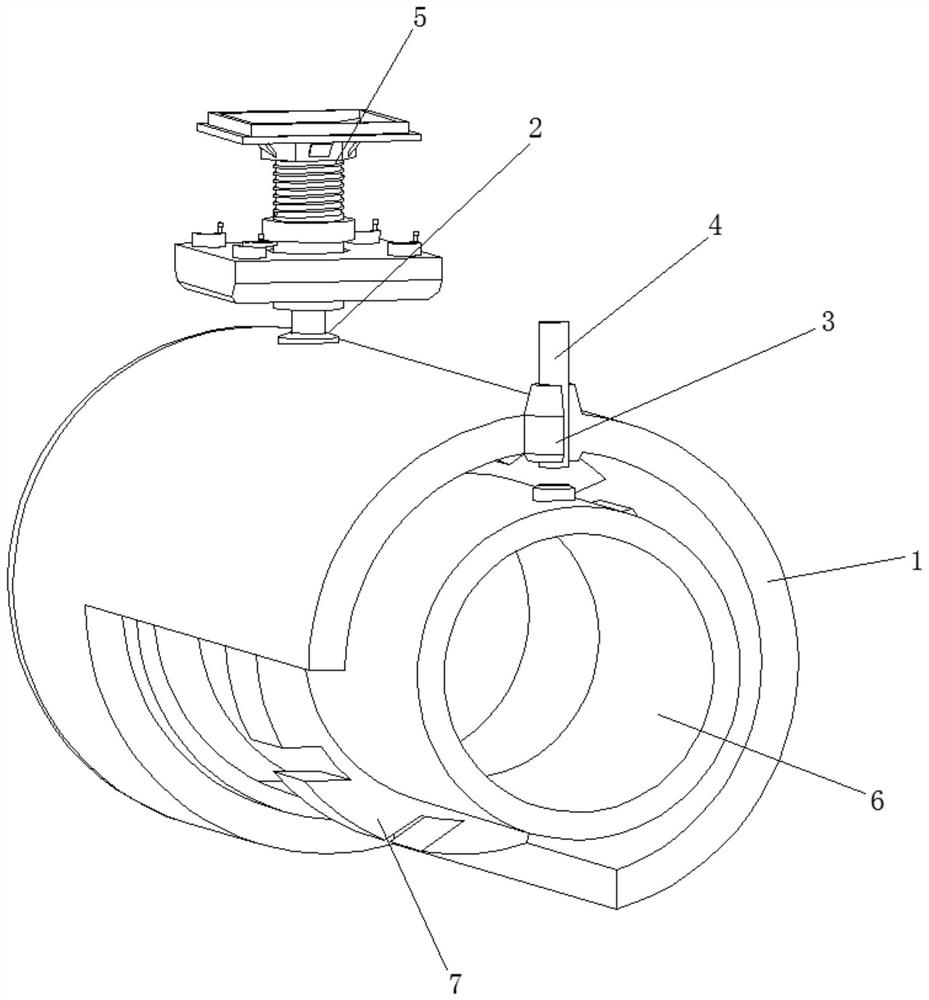

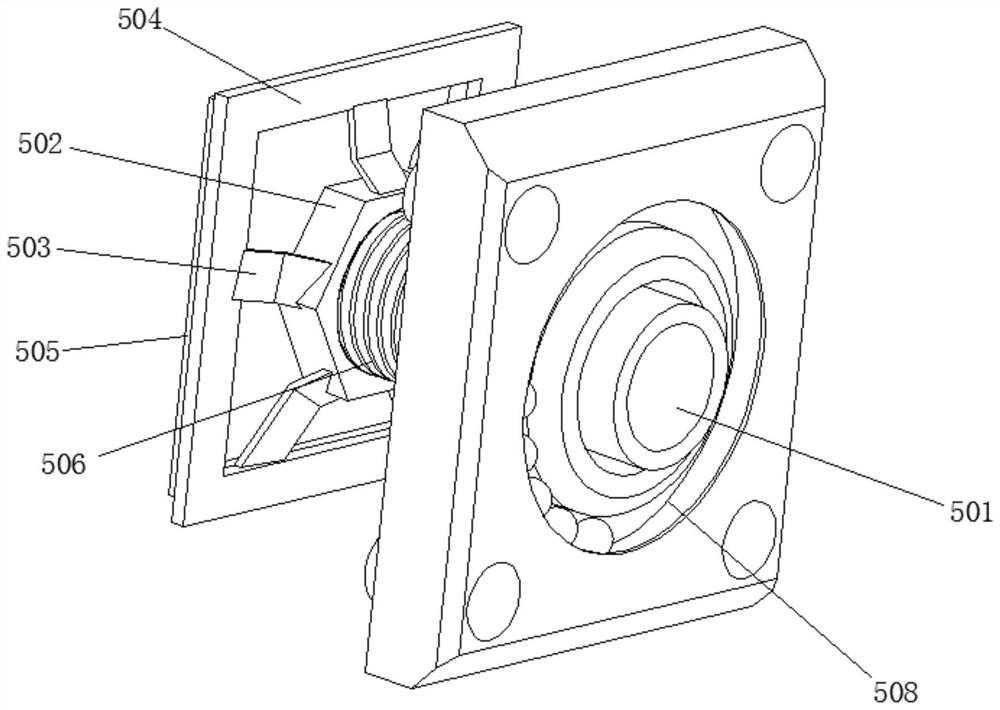

[0031] see Figure 1-6 , the present invention provides a technical solution: a combined hydraulic cylinder with a floating cylinder body, including a hydraulic housing 1, a circular groove 2 is opened on the left and right sides of the top of the hydraulic housing 1, and the inner surface of the circular groove 2 is fixedly connected There is an anti-leakage ring 3, the inner surface of the anti-leakage ring 3 is fixedly connected with a conduit 4, the outer surface of the conduit 4 is movably connected with a buffer mechanism 5, the inner surface of the hydraulic housing 1 is slidably connected with a sliding cavity 6, the sliding cavity 6 The outer surface is provided with an anti-skid mechanism 7, the left side of the hydraulic housing 1 is connected with a frame tube 8 through a fixed cylinder, and the left side of the inner surface of the hydraulic housing 1 is fixedly connected with an anti-collision ring 9; when the hydraulic cylinder has a large kinetic energy, Both t...

Embodiment 2

[0042] see Figure 7 , the present invention provides a technical solution: the anti-slip mechanism 7 includes a circular hole 701, the inner surface of the anti-collision ring 9 is fixedly connected with the outer surface of the circular hole 701, and the inner surface of the circular hole 701 is fixedly connected with the outer surface of the left conduit 4, The outer surface of the sliding cavity 6 is fixedly connected with an anti-slip ring 702 , the outer surface of the anti-slip ring 702 is slidably connected with the inner surface of the hydraulic housing 1 , and the outer surface of the sliding cavity 6 is rotatably connected with a driving wheel 703 . After the hydraulic housing 1 enters the liquid, it is impacted by the liquid, and the driving wheel 703 rotates, which will also accelerate the speed of the liquid entering the hydraulic housing 1, and at the same time accelerate the reciprocating speed of the entire hydraulic cylinder, and cooperate with the internal an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com