Steering tube type electric power assisting device

A steering column and electric power assist technology, applied in steering mechanism, electric steering mechanism, power steering mechanism, etc., can solve the problems of difficult installation and disassembly, affecting the output torque, occupying a large space, etc., and achieving flexible steering operation. , The effect of increasing the output torque and taking up less space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

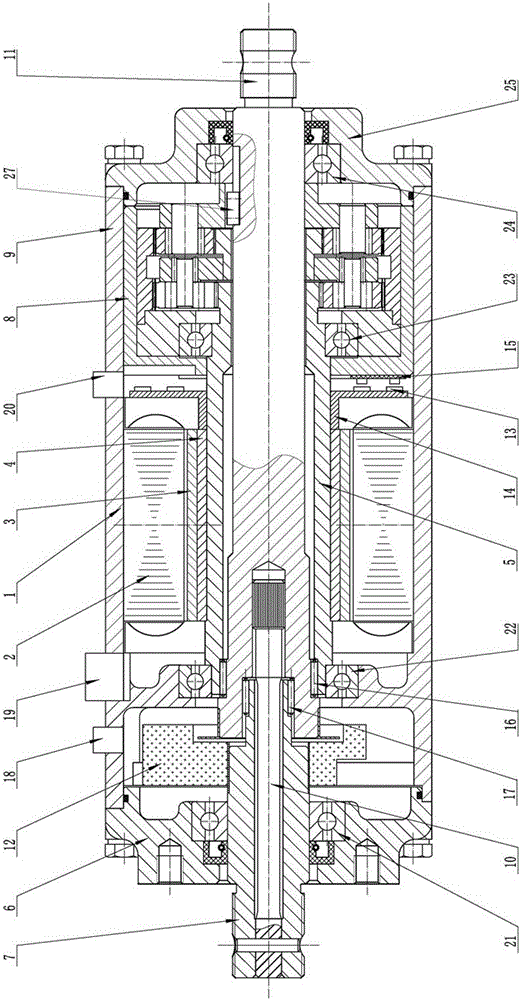

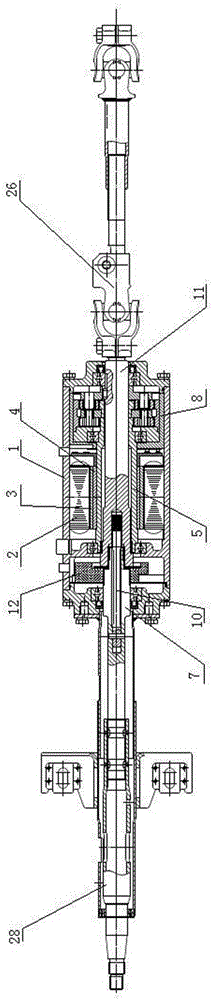

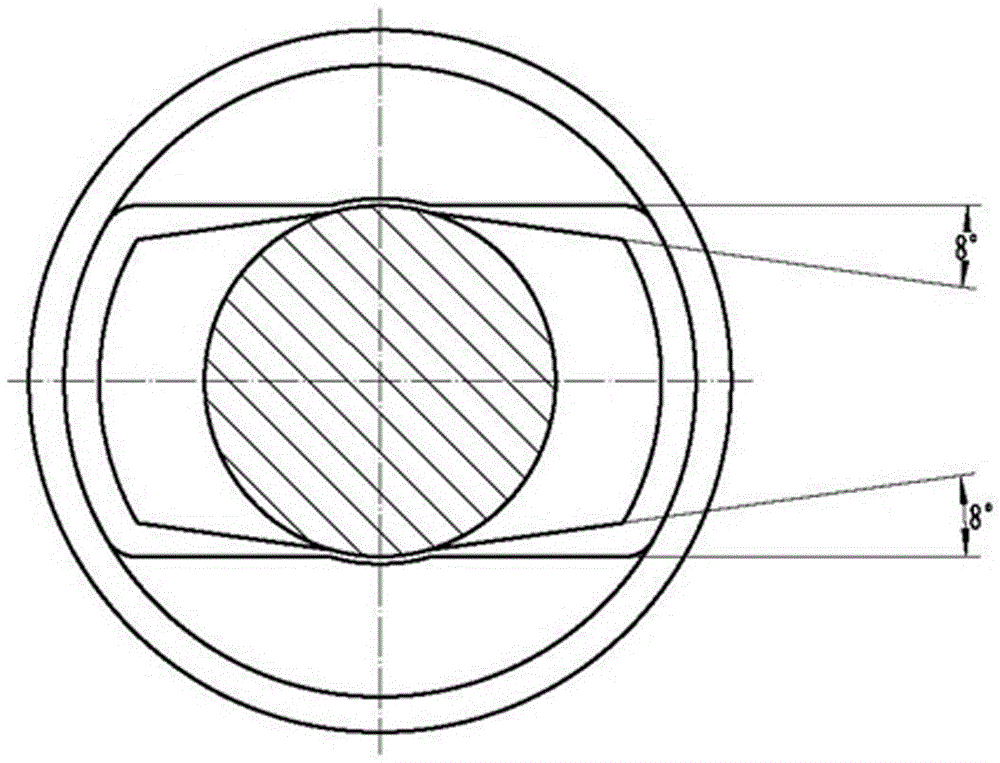

[0011] A new type of steering column type electric power booster according to the present invention includes a housing 1, which is integrated with a diaphragm, and a torque angle sensor 12 is installed on one side of the diaphragm input shaft 7 of the housing 1, and a hollow type sensor 12 is installed in the middle. The inner rotor brushless motor, the planetary gear reducer 8 is installed on the side of the output shaft 11 of the casing 1. The coil stator 2 of the hollow inner rotor brushless motor is fixedly connected with the inner wall of the housing 1, and the magnetic steel rotor 3 is fixedly installed on the outside of the sleeve 4, and the sleeve 4 is fixedly installed on the sleeve shaft 5, and one end of the sleeve shaft 5 passes through The second positioning bearing 22 is connected with the diaphragm, and the other end of the sleeve shaft 5 is positioned and connected with the planetary gear reducer 8 through the third positioning bearing 23. The lower end of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com