Pavement repairing device for concrete road maintenance

A technology for road maintenance and pavement repair, which is applied in road repair, roads, roads, etc. It can solve the problems of repeated construction injection, poor effect, waste of road repair agent and complicated cleaning, and achieve the effect of prolonging the polymerization time and improving the repair effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

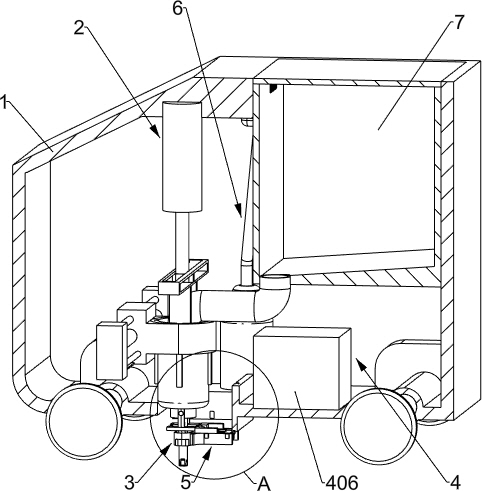

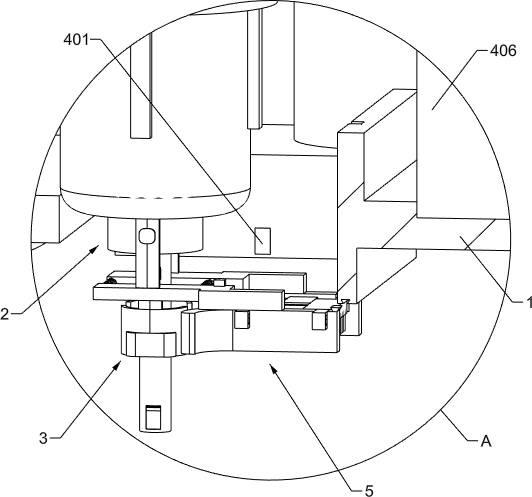

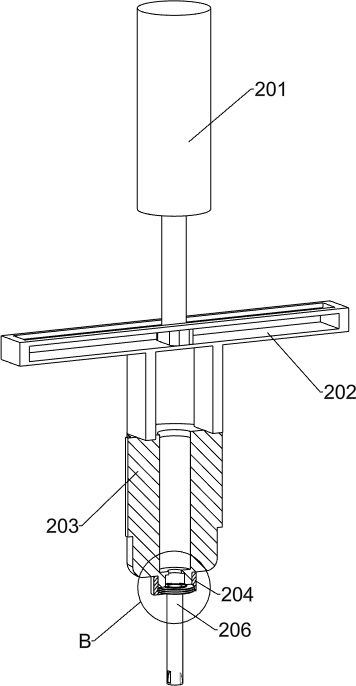

[0032] A road surface patching device for concrete road maintenance, such as figure 1 and figure 2 As shown, it includes an electric trolley 1, a perfusion device 2, a positioning device 3 and an information processing module 4. The electric trolley 1 is placed above the road cracks, and cooperates with its internal device to complete the repair of the road cracks. The electric trolley 1 is fixed There are perfusion device 2 and positioning device 3. There is a through hole on the left part of the lower surface of the electric trolley 1, which is used for protruding and recovering the perfusion device 2 and positioning device 3. There is a through hole on the right part of the upper surface of the electric trolley 1. The electric trolley 1. There are mounting plates on the front and rear sides around the opening on the lower surface. There are mounting plates symmetrically arranged up and down on the right side of the opening on the lower surface of electric trolley 1. Two ch...

Embodiment 2

[0041] On the basis of Example 1, such as Figure 8 and Figure 9 As shown, a margin adjustment device 5 is also included, and the margin adjustment device 5 is fixedly connected to the positioning device 3. The margin adjustment device 5 includes a bending baffle 501, a trapezoidal slider 502, a trapezoidal limit block 503, a trapezoidal The connection block 504, the first brush seat 505, the second brush seat 506, the third brush seat 507, the third spring 508 and the bristles 509, the bending baffle plate 501 and the trapezoidal slide block 502 are respectively provided with two front and rear symmetrical The middle part of the upper surface of the bent baffle 501 is respectively fixed on the lower surface of the right part of the Z-shaped connecting block 306. Each bent baffle 501 is provided with two placement grooves and the upper surface of the right part is fixed with a trapezoidal slider 502. The folding baffle 501 is close to the ground and its left end is outwardly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com