Muck storage and outflow recording equipment for muck management

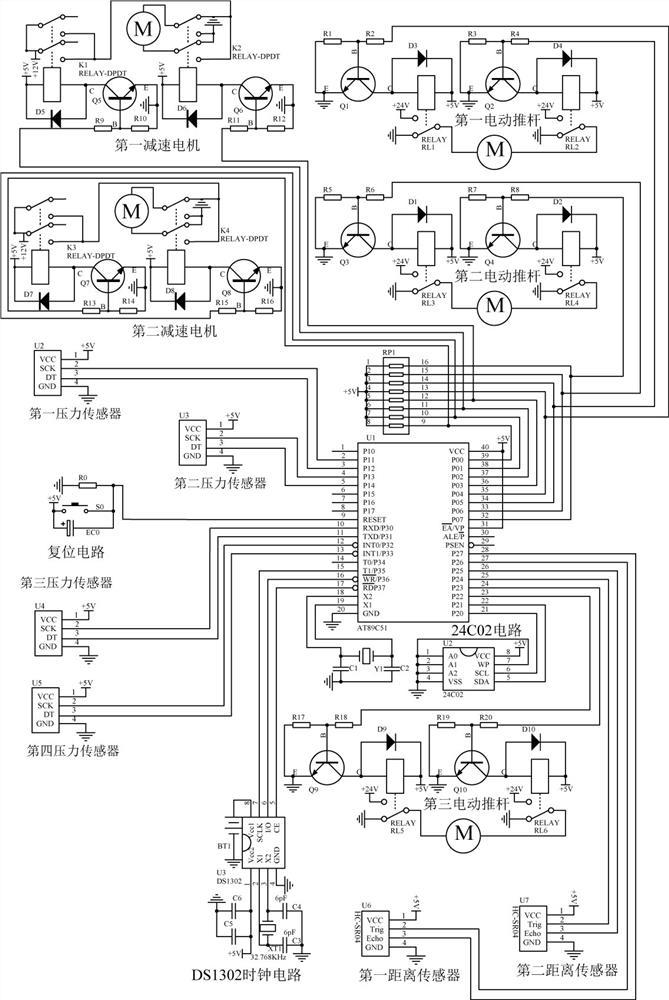

A technology for recording equipment and dregs, which is applied to the processing of building materials, roads, instruments, etc., can solve the problems of reduced practicality, errors in data recording, and inability to adjust the height of equipment to achieve the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

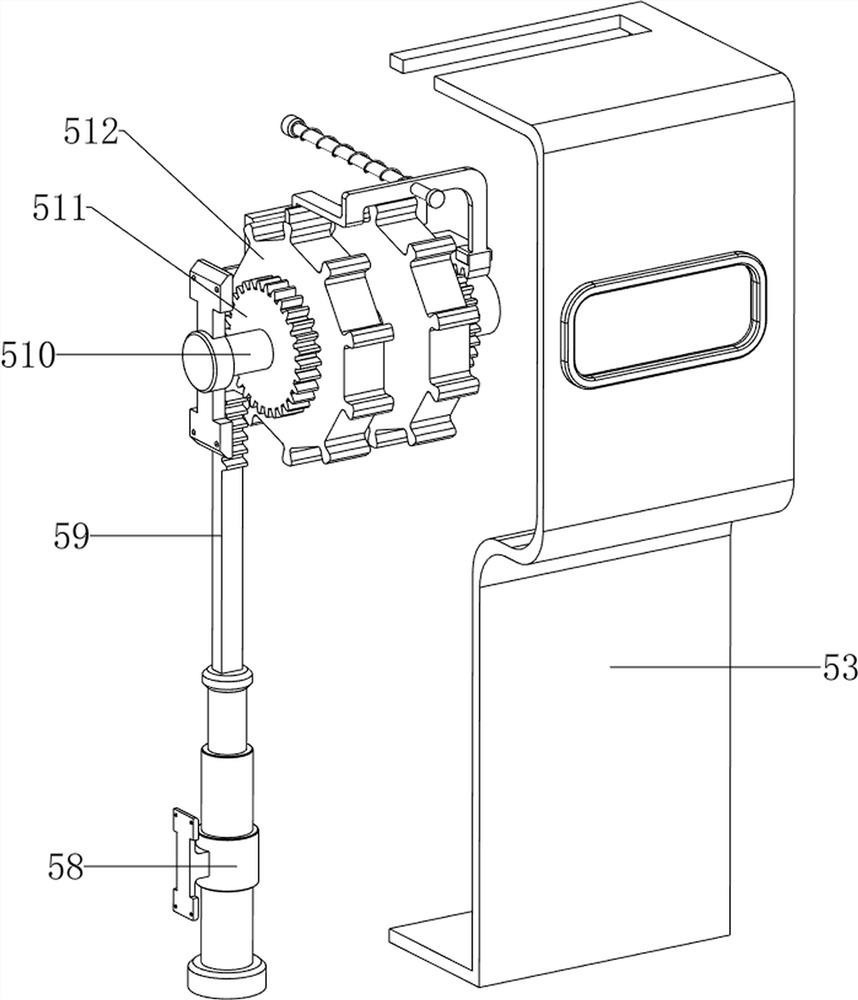

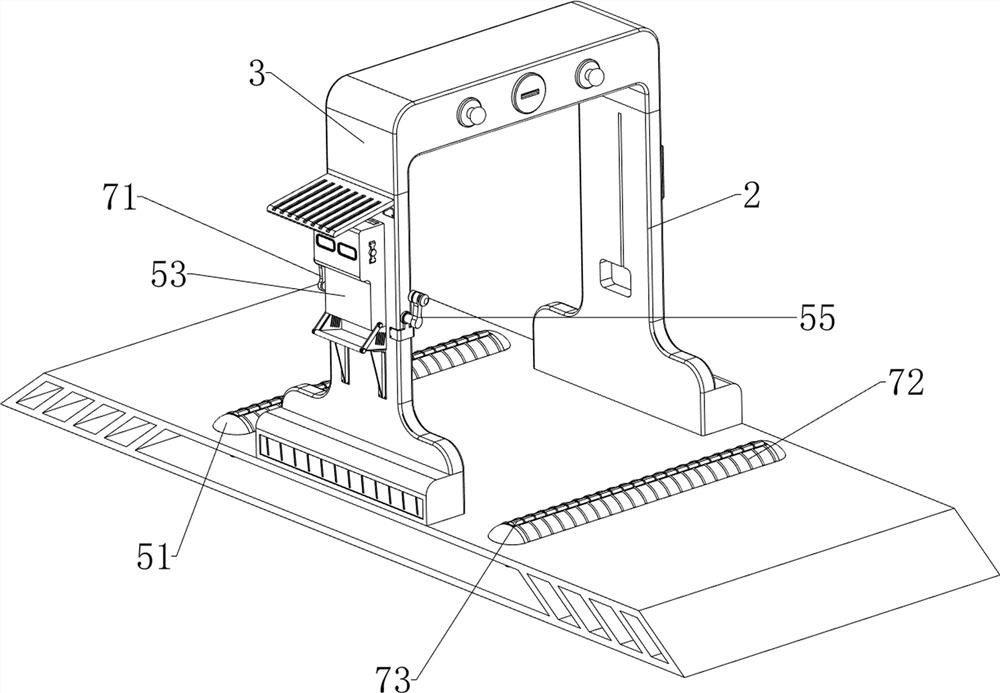

[0042] A muck storage and outflow recording device for muck management, such as Figure 1-22 As shown, it includes a first mounting plate 1, a first mounting block 2, a telescopic block 3, an outflow mechanism 5, a pushing mechanism 6 and a storage mechanism 7, and the first mounting block 2 is symmetrically arranged in the middle of the top of the first mounting plate 1. The telescopic block 3 is slidingly arranged between the top of the first mounting block 2, and the top left side of the first mounting plate 1 is provided with an outflow mechanism 5, and the upper rear side of the first mounting block 2 on the rear side is provided with a pushing mechanism 6, and the front side A storage mechanism 7 is provided on the left side of the middle part of the first mounting block 2 .

[0043] The outflow mechanism 5 includes a first deceleration belt 51, a first pressure sensor 52, a mounting frame 53, a rain shield 54, a first distance sensor 55, a first sliding sleeve 56, a fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com