Air storage tank pressure testing machine

A technology of gas storage tanks and pressure testing machines, which is applied in the field of pressure testing machines, can solve problems such as low detection efficiency and cumbersome process, and achieve intuitive experimental results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

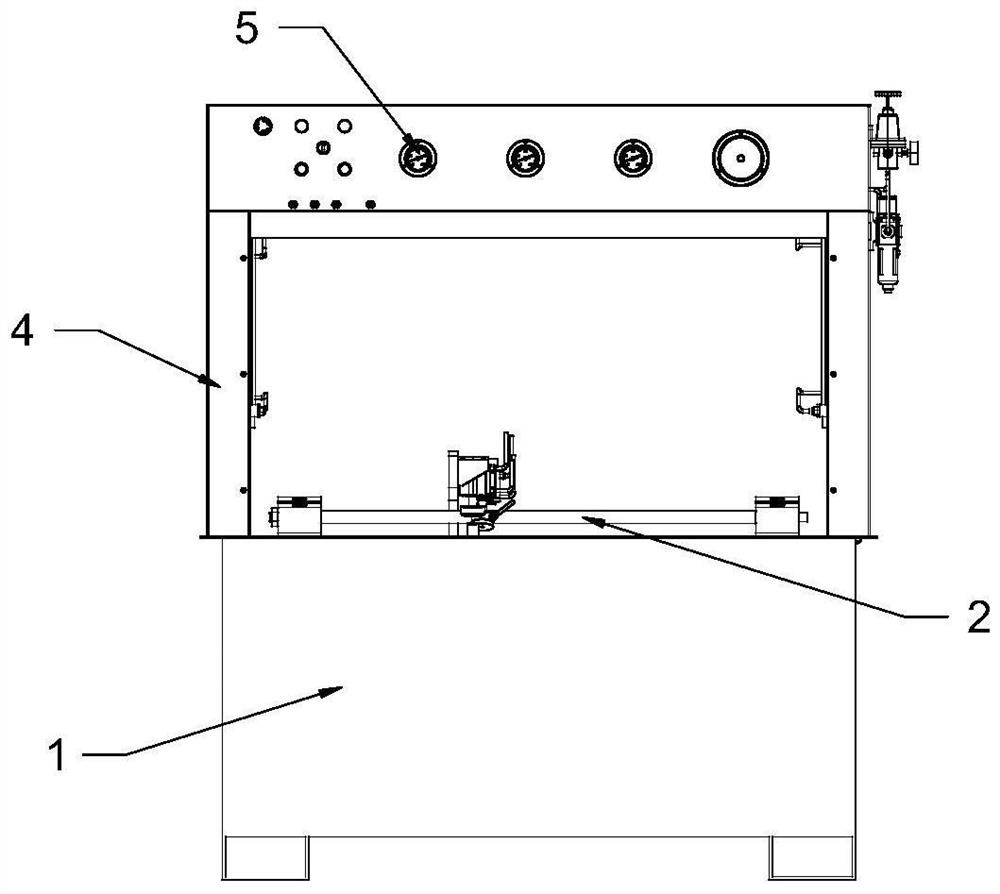

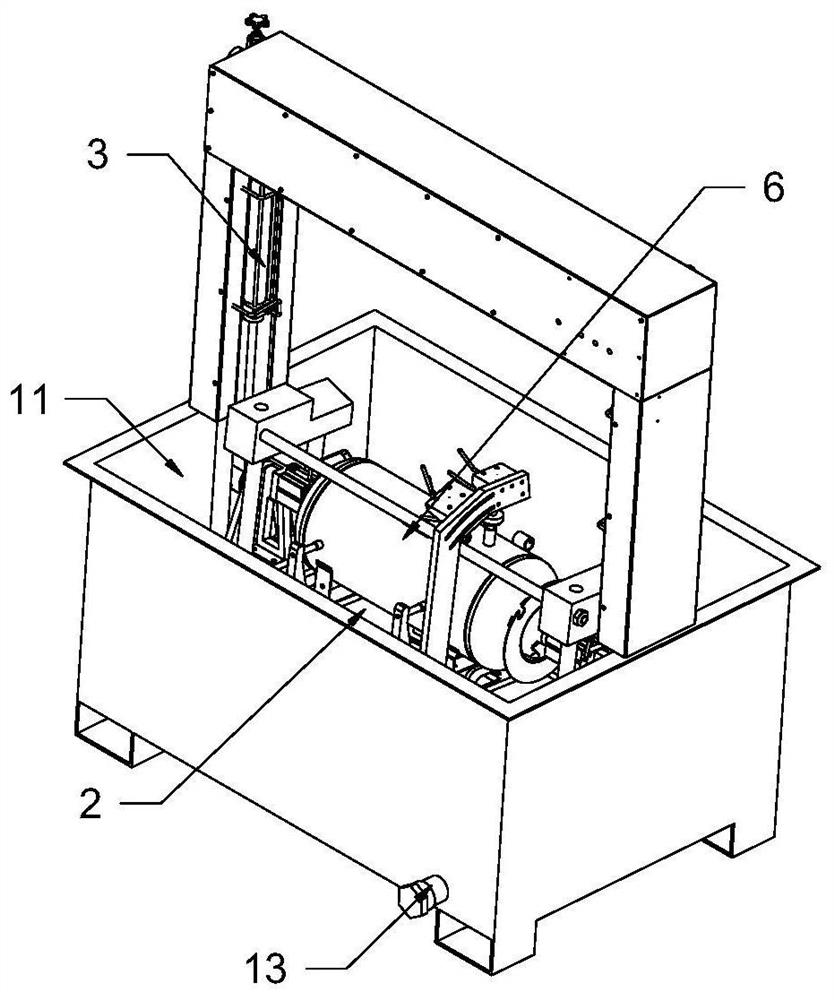

[0024] like Figure 1 to 8 As shown, a gas tank test press includes a water tank 1, a clamp tooling 2, a lifting assembly 3, a bracket 4, and an electrical control assembly 5. The opening 11 is disposed in the upper portion of the water tank 1, and the fixture tool 2 is located inside the water tank 1 and can be removed from the opening 11, and the clamp tool 2 is used to secure the gas storage tank 6 and the gas storage tank 6 is inflated and charged. Connect the lift assembly 3 on the clamp tool 2, and the lifting assembly 3 controls the lifting of the fixture tool 2. The lifting assembly 3 is fixedly mounted on the bracket 4, and the bracket 4 is located on both sides of the water tank 1, and the electrical control assembly 5 is provided on the bracket 4, the electrical control assembly 5 controls the fixture tool 2 and the lifting assembly 3.

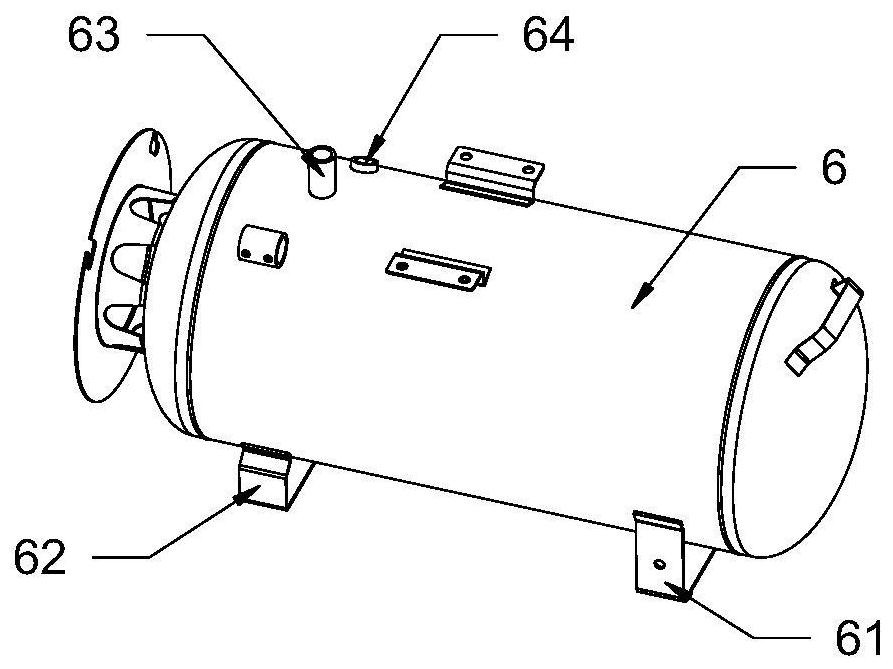

[0025] like image 3 and Figure 4 As shown, the can body of the gas storage tank 6 is a cylindrical and laterally disposed, and the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com