Method for predicting spraying time of machine-harvested cotton defoliant

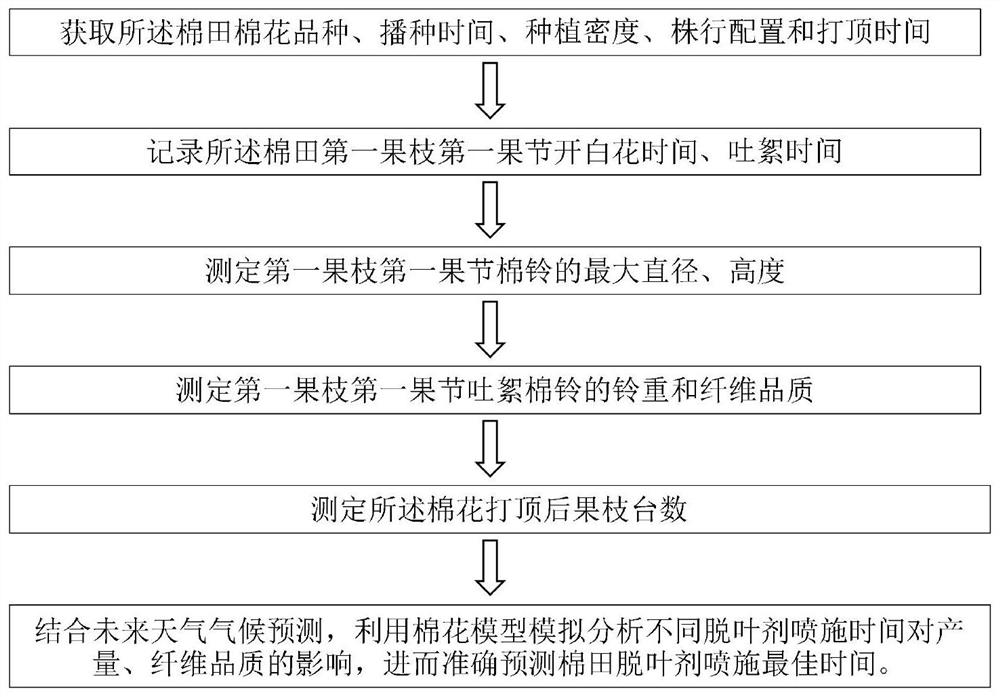

A cotton defoliant and prediction method technology, which is applied in the direction of mechanical clearance measurement, prediction, mechanical diameter measurement, etc., can solve the inability to accurately predict the time of the defoliant, the deviation of specific varieties, and the inability to quantitatively reflect the impact of yield and quality, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

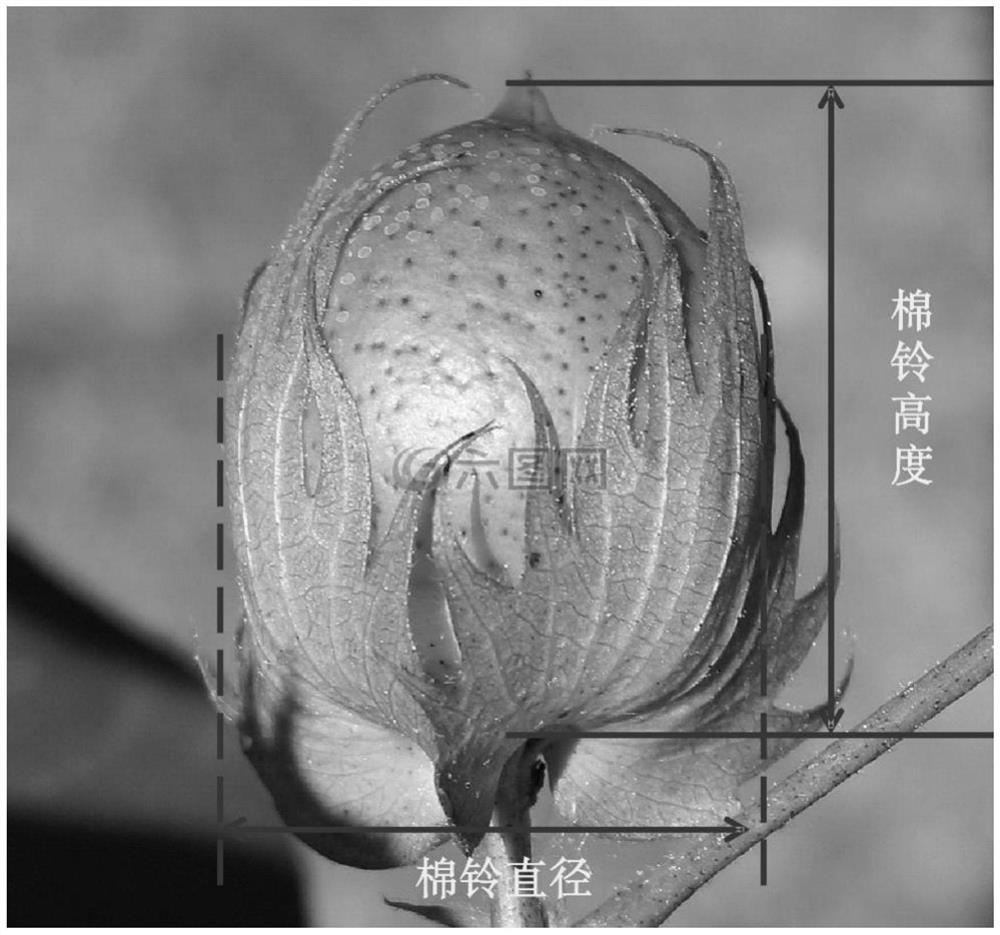

Method used

Image

Examples

Embodiment

[0035] 1. Overview of the research area

[0036] The research area is located in the 143rd Regiment of the 8th Division of the Xinjiang Production and Construction Corps. The tested variety is Xinluzao 78, and the planting scale is 100 mu. Among them, 30 mu is the application area, and 70 mu is the control area.

[0037] 2. Experimental design

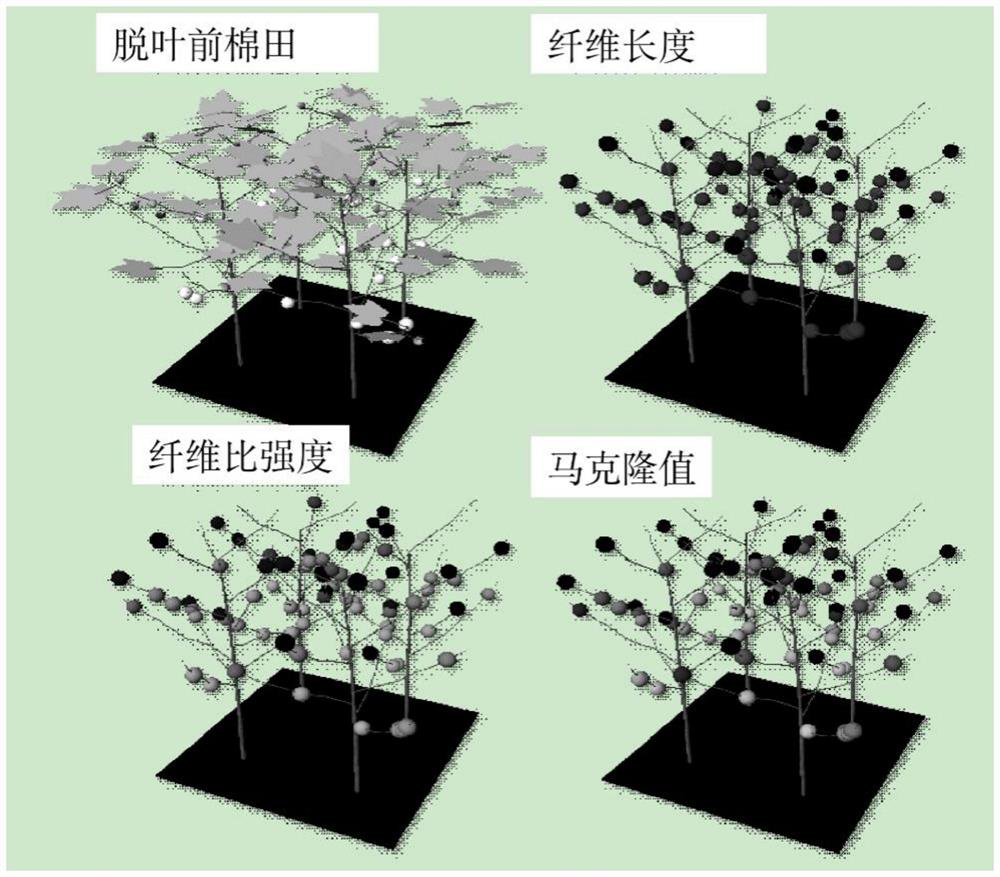

[0038] All management in the study area is carried out in a unified manner. After the cotton field was opened, the defoliation time was selected in the control area according to the identification method of the local conventional defoliant spraying time. The application area collects various basic data, adjusts the parameters of the cotton functional structure model Cotton XL, and evaluates the accuracy of the model simulation by using the root mean square error and fitting degree of the measured and simulated values. Cotton XL, a cotton functional structure model, was used to simulate and analyze the effects of different spraying t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com