Optical module, receptacle equipped with isolator, and optical unit

An optical isolator, optical module technology, applied in optical components, instruments, optics, etc., can solve the problems of LD damage, wavelength deviation, variation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0016] The various embodiments are described in detail below with reference to the drawings.

[0017]

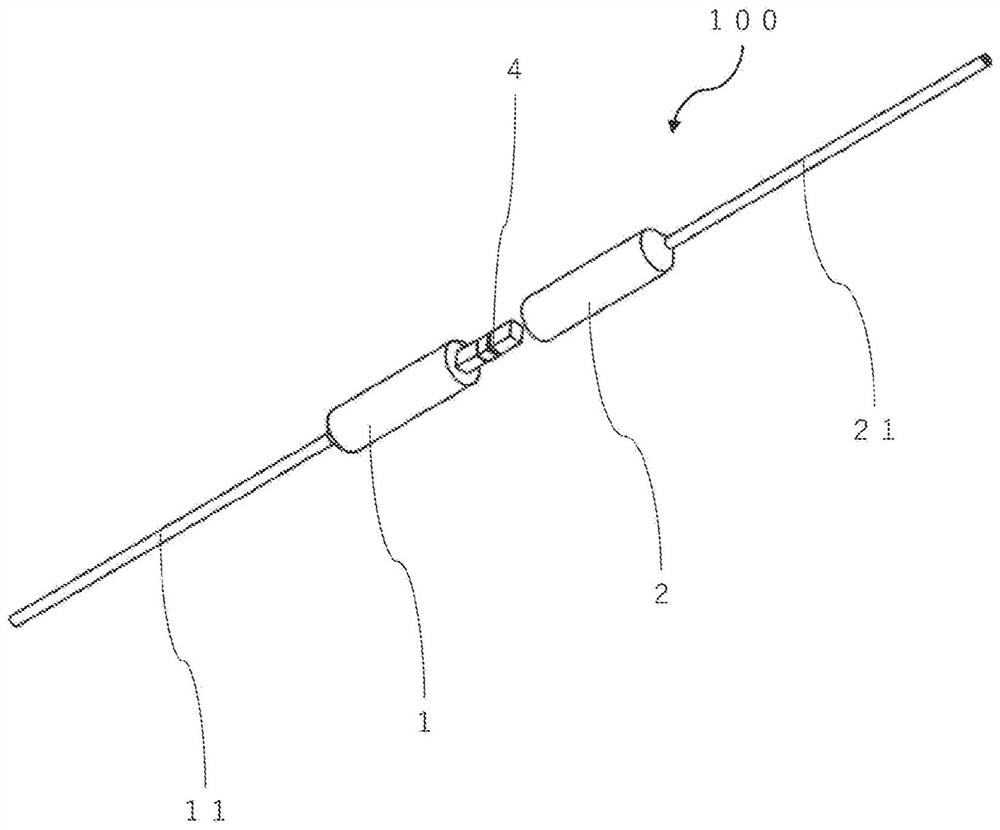

[0018] like figure 1 As shown, the present disclosure optical module 10 includes a first ferrule 1, a second ferrule 2, and a polarization-independent optical isolator 3.

[0019] The first ferrule 1 is, for example, a cylindrical shape or a cylinder shape. The first socket 1 is, for example, the size of the diameter is The length is 2.0mm ~ 10mm. exist figure 1 In the present, the optical fiber is shown in reference numerals 11, 12.

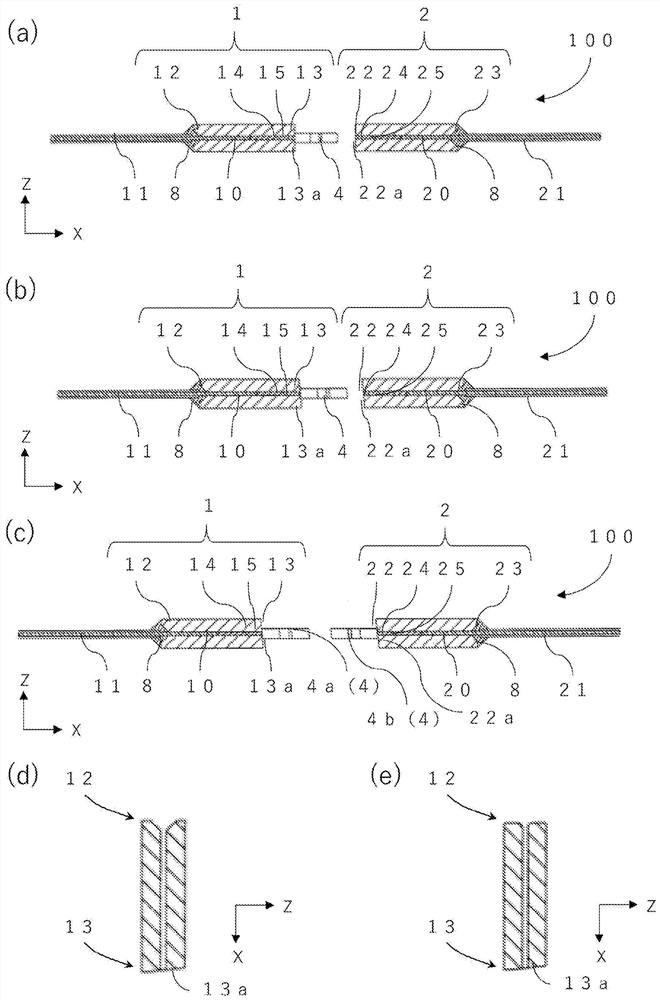

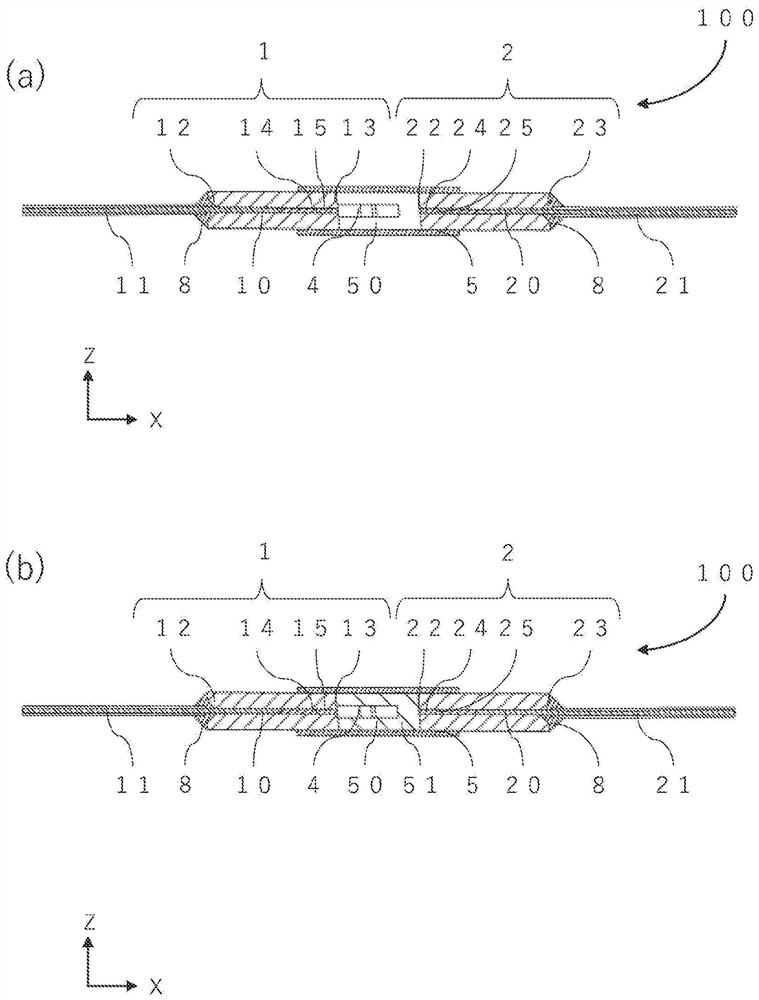

[0020] like figure 2 As shown, the first ferrule 1 includes a first end portion 12, a second end portion 13, and a first through hole 10 that penetrates the first end portion 12 and the second end portion 13. Here, the direction of the forward direction is figure 2 The light source in the X-axis direction, the light of the light source from the outside of the LD is incident on the opening of the first end portion 12, and is emitted from the open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com