A device and method for automatically cutting and storing textile materials

An automatic cutting and storage device technology, which is applied in the cutting of textile materials, textiles and papermaking, and spreading of thin soft materials, etc., can solve problems such as blanking wrinkles, achieve smooth blanking, improve flatness, and ensure cloth cutting efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

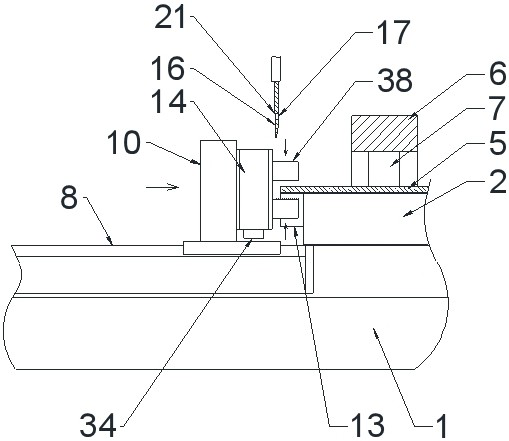

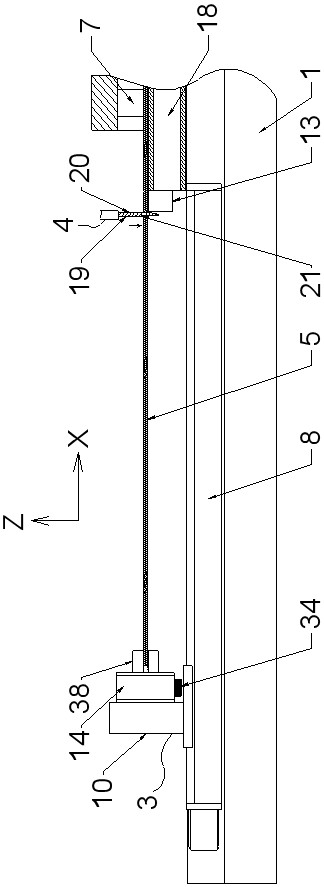

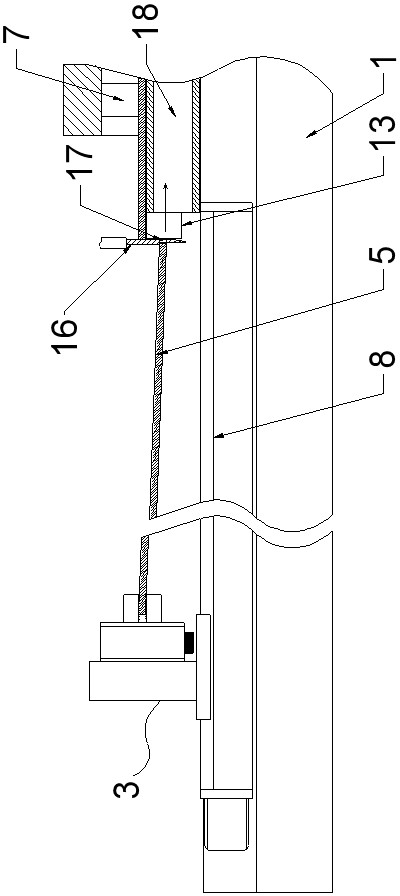

[0042] like Figure 1 to Figure 5 As shown, this embodiment provides an automatic cutting and storage device for textile materials, including: a frame 1 , a feeding table 2 , a cloth pulling mechanism 3 and a cloth cutting mechanism 4 .

[0043]Feeding platform 2 is installed on the rear side of frame 1, and is used for supporting the cloth 5 of unwinding, and the rear side of feeding platform 2 on frame 1 is installed rotatable unwinding roller (not shown in the figure) along Y-axis direction, The cloth 5 is wound on the unwinding roller, and the end of the cloth 5 is drawn out from the unwinding roller and placed on the front end of the feed table 2 .

[0044] Please refer to figure 1 , a gantry 6 is installed on the frame 1 above the feeding platform 2, and the cloth pressing part 7 is placed on the gantry 6, and the cloth pressing part 7 is pressed on the cloth 5, which exerts a certain amount of pressure on the cloth 5 to prevent the cloth 5 from cutting. Glides freely ...

Embodiment 2

[0069] The difference between this embodiment and Embodiment 1 is that this embodiment can further brush flat cloth. Please refer to figure 2 and Figure 8 A brush body 34 is installed on the support plate 10, the brush body 34 can be fixed under the finger cylinder, or fixed at the bottom of a horizontally arranged plate, and the brush body 34 has soft bristles. On the path where the X-axis driver 8 drives the cloth clamping cylinder group 11 to move to the feeding table 2, the brush body 34 brushes the entire width of the cloth 5 on the top of the storage table 22 to further improve the flatness of the cloth. The finishing process does not require additional man-hours and does not affect the cutting efficiency.

[0070] Please refer to Figure 8 to Figure 9 On the frame 1, a cylinder block 35 is installed in front of the material storage platform 22, and a row of corner cylinders 36 are installed along the Y-axis direction on the cylinder block 35, and the controller is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com