Automatic identification method for pouring gate of cast-in-place mold

An automatic identification and pouring gate technology, which is applied in character and pattern recognition, construction, building structure, etc., can solve problems such as labor-intensive, slurry leakage construction errors, and inability to realize real-time monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

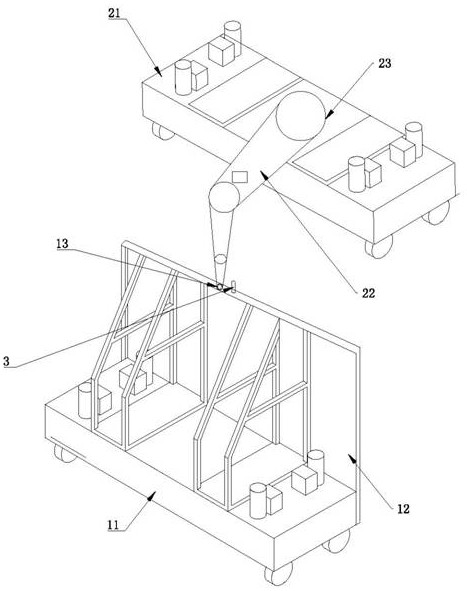

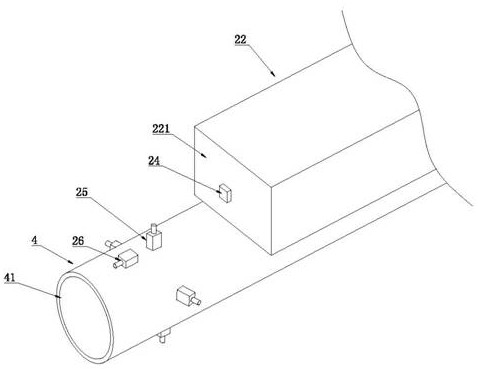

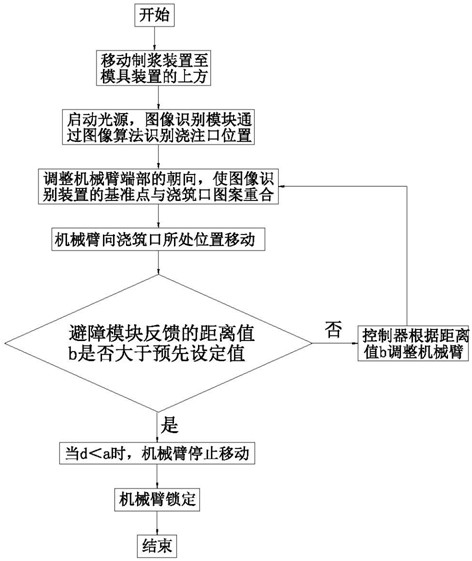

[0029] Such as Figure 1-Figure 4 As shown, a method for automatic identification of the pouring port of a cast-in-place mold includes two relatively set mold devices, a pulping device, and a light source 3. After the two mold devices contact each other, a cavity for accommodating the pouring slurry is formed. The mold device The upper end is provided with a pouring port 13 for pouring slurry; the light source 3 is arranged on the mold device; the slurry making device is located above the pouring port 13, and the cross section of the pouring port 13 is circular.

[0030] The mold device includes a mold body 11 and a formwork 12 for pouring and molding. The formwork 12 is arranged on one side of the mold body 11, the pouring port 13 is arranged on the top surface of the formwork 12, and the light source 3 is arranged on the top surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com