Motor and magnetic brake

A magnetic brake and magnetic brake technology, applied in the direction of motors, electric vehicles, electrical components, etc., can solve the problems of inability to complete automatic parking, poor applicability of in-wheel motors, etc., to facilitate motor assembly, eliminate accumulated errors, and meet parking requirements. The effect of the hill brake function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

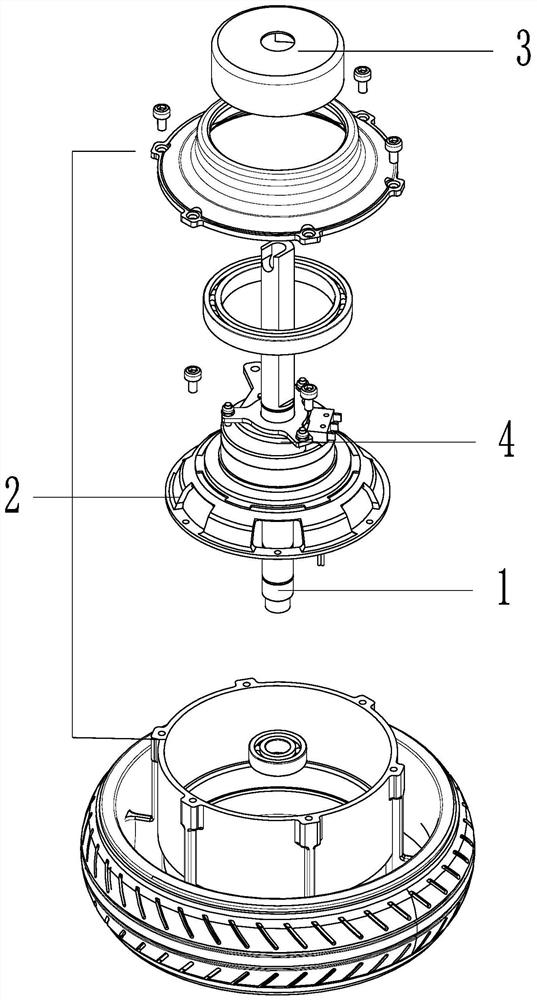

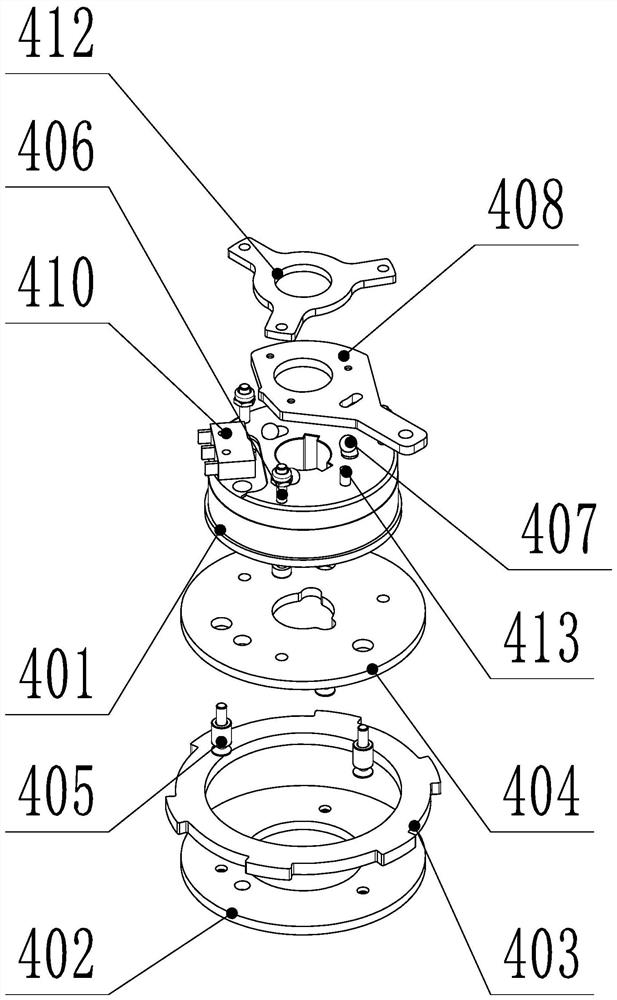

[0031] The motor of this embodiment is as figure 1 As shown, it is composed of a stator assembly 1, a rotor assembly 2 and a magnetic brake 4, and a magnetic brake protective cover 3 for waterproof and dustproof is installed on the magnetic brake 4.

[0032] In the stator assembly 1, the stator punches are stacked and wound to assemble the electric appliance, and then connected to the motor shaft through a flat key. The magnetic steel sheet is attached to the inner side of the rotor, and the other side of the rotor is screwed to the gear train components, connected through the sun gear, planetary gear, ring gear and hub, to reduce the output of the motor and increase the torque.

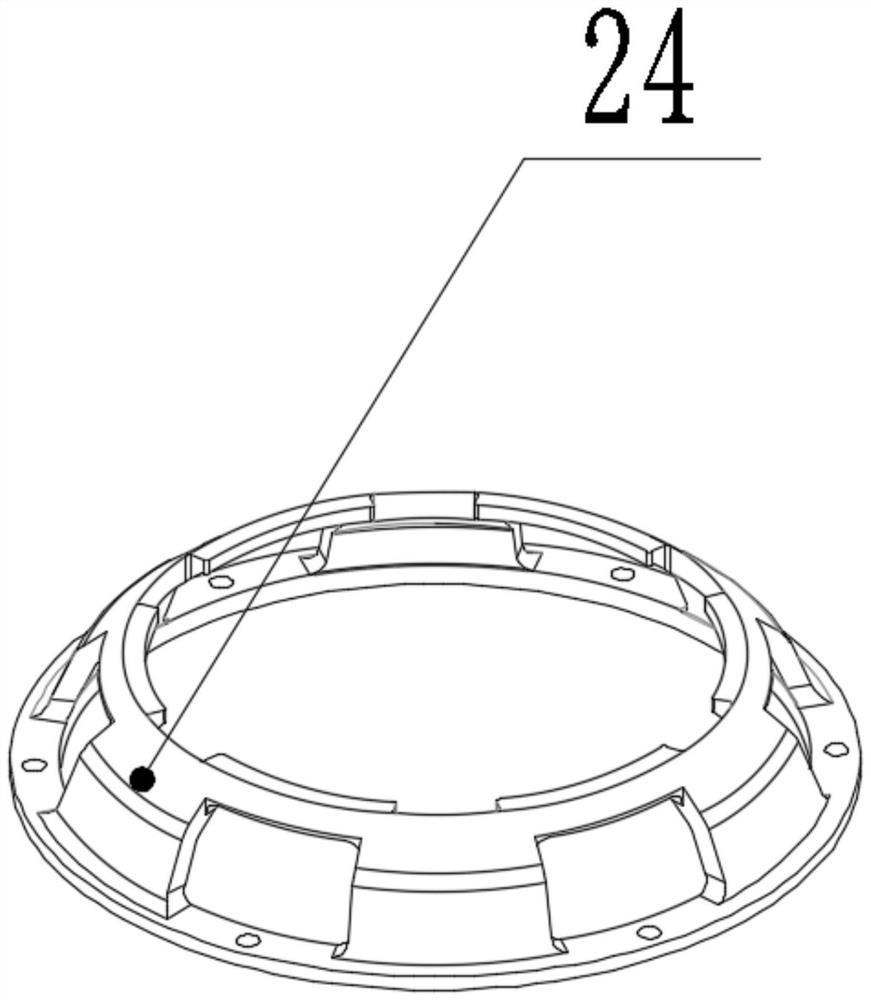

[0033] In the rotor assembly 2 , the rotor opening side is screwed and fixed to the rotor cover 24 , and the rotor assembly is used to convert electrical energy into kinetic energy. Such as figure 2 The rotor cover 24 shown has a slot matching the ear on the outer circumference of the friction pla...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap