Railway vehicle noise reduction floor

A technology for rail vehicles and floors, used in railway car bodies, railway car body parts, instruments, etc., can solve the problems of poor sound insulation and sound absorption performance, improve sound insulation and sound absorption performance, meet the requirements of noise reduction, The effect of improving ride comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

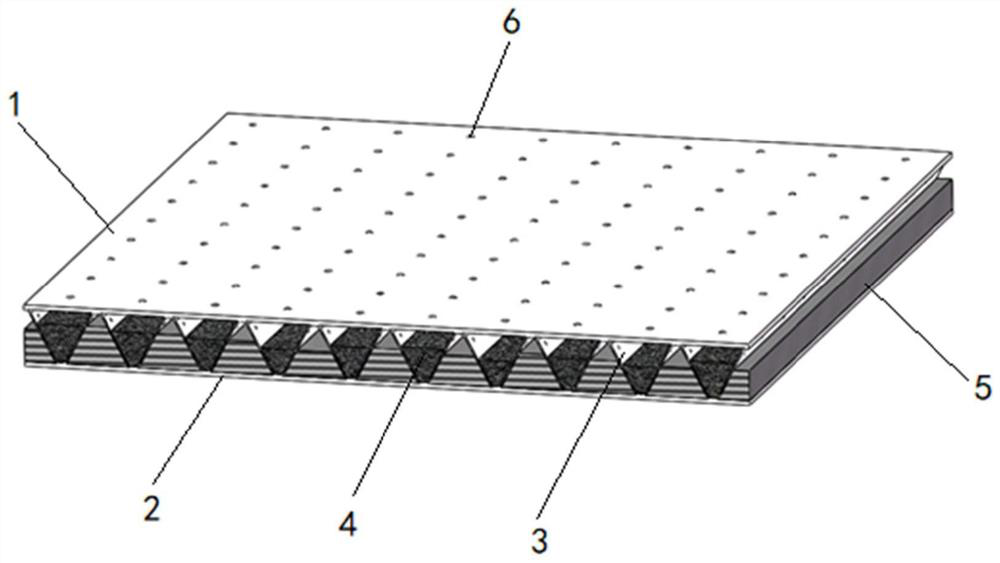

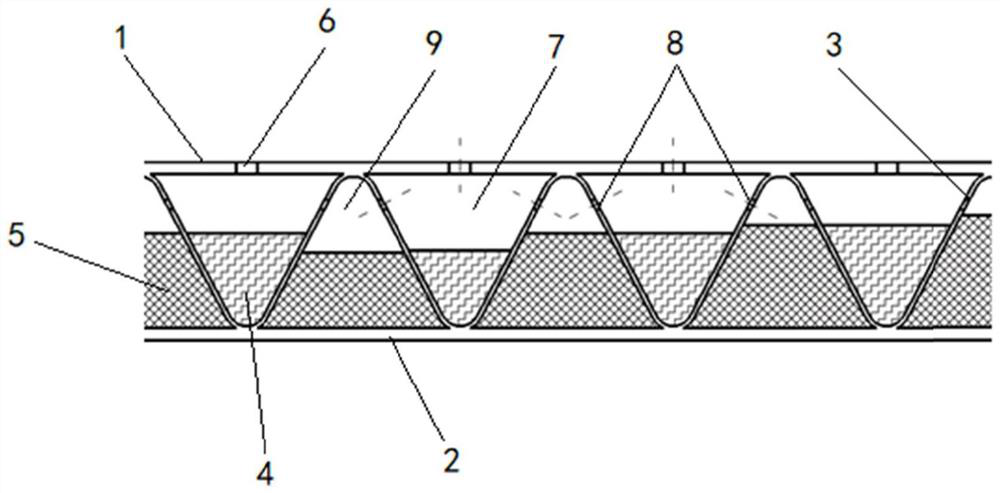

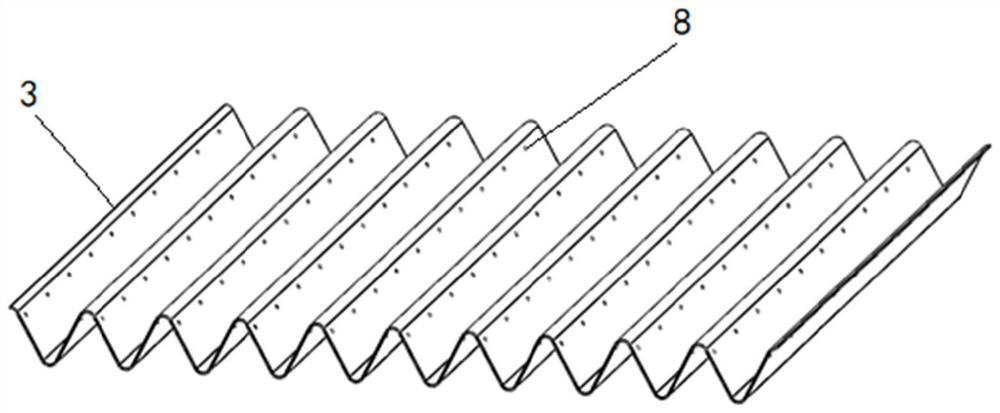

[0025] Such as Figure 1 to Figure 3 As shown, the rail vehicle noise reduction floor of the present invention includes: an upper panel 1, a lower panel 2 and a corrugated board 3, the upper panel 1 and the corrugated board 3 are provided with micro-holes, and the height of the corrugated board 3 is 20 mm to 40 mm. The upper panel 1, the corrugated plate 3 and the lower panel 2 are fixedly connected sequentially from top to bottom, the upper panel 1 is connected with the corrugated plate 3 to form a plurality of wave valley cavities 7, and the lower panel 2 is connected with the corrugated plate 3 to form a plurality of wave crest cavities 9 . The valley cavity 7 is filled with a first sound-absorbing material 4, and the peak cavity 9 is filled with a second sound-absorbing material 5. The first sound-absorbing material 4 and the second sound-absorbing material 5 have different acoustic impedance characteristics respectively, but Porous sound-absorbing materials can be used t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com