Wood fiber-coir fiber composite sound-absorbing material and preparation method thereof

A sound-absorbing material and wood fiber technology, applied in wood treatment, wood impregnation, impregnated wood, etc., can solve the problem that the sound absorption performance cannot meet the expected requirements, and achieve improved sound absorption effect, increased void ratio, and best sound absorption performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The embodiment of the present invention provides a method for preparing wood fiber-coconut fiber composite sound-absorbing material, comprising steps:

[0042] S101, taking wood fiber and coconut fiber, according to the mass ratio of wood fiber and coconut fiber is (1-9): 1 ratio, put wood fiber and coconut fiber into a mixer.

[0043] That is, 1 to 9 parts by mass of wood fiber corresponds to 1 part by mass of coconut fiber, and the quality of coconut fiber accounts for 10% to 50% of the total mass of coconut fiber and wood fiber.

[0044] S102, taking urea-formaldehyde resin glue, the amount of which is 5% to 12% of the sum of the mass of wood fiber and coconut fiber.

[0045] S103, adding a curing agent to the urea-formaldehyde resin glue, the amount of the curing agent added is 1% of the mass of the urea-formaldehyde resin glue.

[0046] S104, adding a foaming agent in an amount of 16% to 48% of the mass of the urea-formaldehyde resin glue to obtain a glue solution...

Embodiment 2

[0051] Embodiment 2 of the present invention is another embodiment of the preparation method of wood fiber-coir fiber composite sound-absorbing material, and this embodiment comprises steps:

[0052] S201, taking wood fiber and coconut fiber, according to the mass ratio of wood fiber and coconut fiber is 9:1, that is, the mass of coconut fiber accounts for 10%, put the wood fiber and coconut fiber into the mixer.

[0053] S202, get urea-formaldehyde resin glue, and the sizing amount is 5% of the sum of wood fiber and coconut fiber quality;

[0054] S203, adding a curing agent to the urea-formaldehyde resin glue, the amount of the curing agent added is 1% of the mass of the urea-formaldehyde resin glue.

[0055] Preferably, in this embodiment, the curing agent is ammonium chloride.

[0056] S204, then adding zinc oxide and azodicarbonamide as a foaming agent, adding the foaming agent, the amount of the foaming agent added is 16% to 48% of the quality of the urea-formaldehyde r...

Embodiment 3

[0061] Embodiment 3 of the present invention is another embodiment of the preparation method of wood fiber-coir fiber composite sound-absorbing material, and this embodiment comprises steps:

[0062] S301, the wood fiber is placed in a sodium hydroxide solution for alkali extraction treatment.

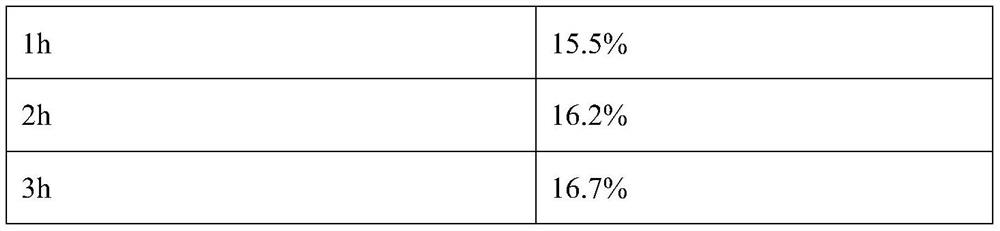

[0063] The concentration of sodium hydroxide is 0.5%-2%; the extraction temperature is 60°C-100°C; the extraction time is 30min-3h. Then put it into an oven for drying, the drying temperature is 120-130 degrees, and the drying time is 6-8 hours.

[0064] S302, putting the coconut fiber into an oven with a drying temperature of 100-110° C. to dry for 30-60 minutes. When the drying is completed and taken out, the fibers are relatively dispersed and there is no longer aggregation.

[0065] S303, taking wood fiber and coconut fiber, according to the ratio of the mass ratio of wood fiber and coconut fiber being 4:1, that is, the mass of coconut fiber accounts for 25%, put the wood fiber an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| sound absorption coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com