Winding and fixing structure for non-woven fabric paper

A fixed structure and cloth paper technology, applied in the field of non-woven paper, can solve the problems of non-woven paper damage, glue cleaning troubles, etc., to achieve the effect of ensuring the quality of winding, ingenious structural design, and eliminating the need for cleaning operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

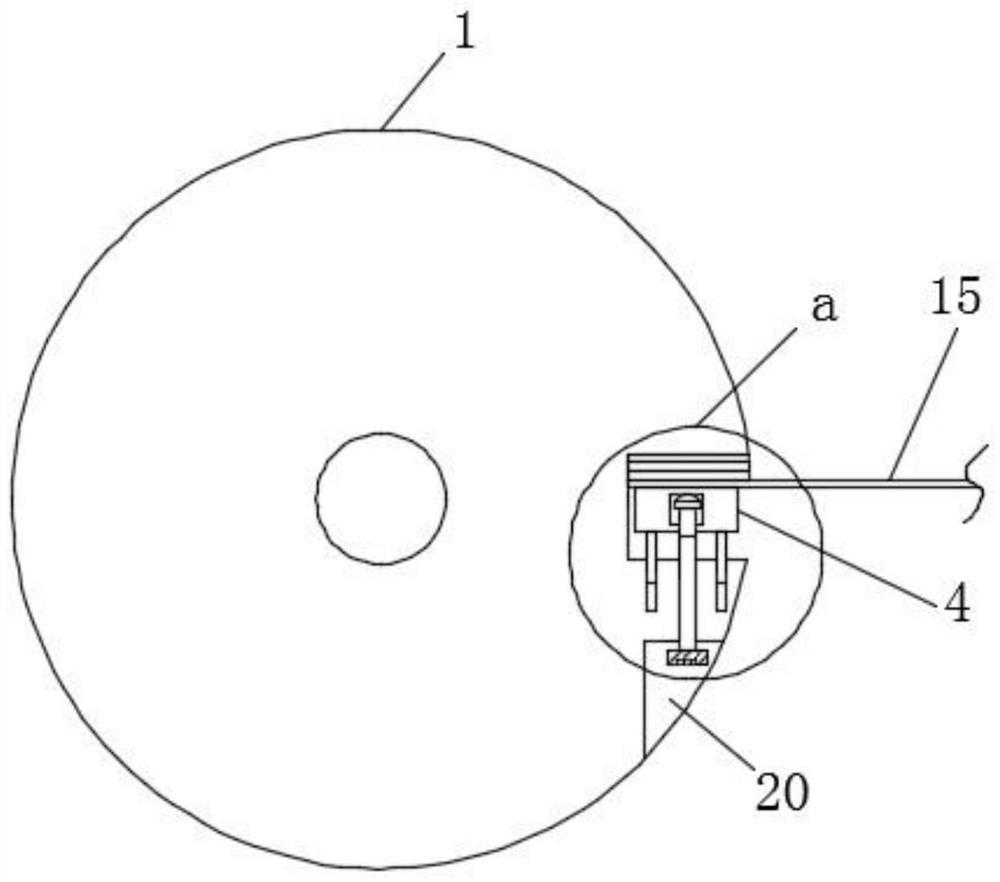

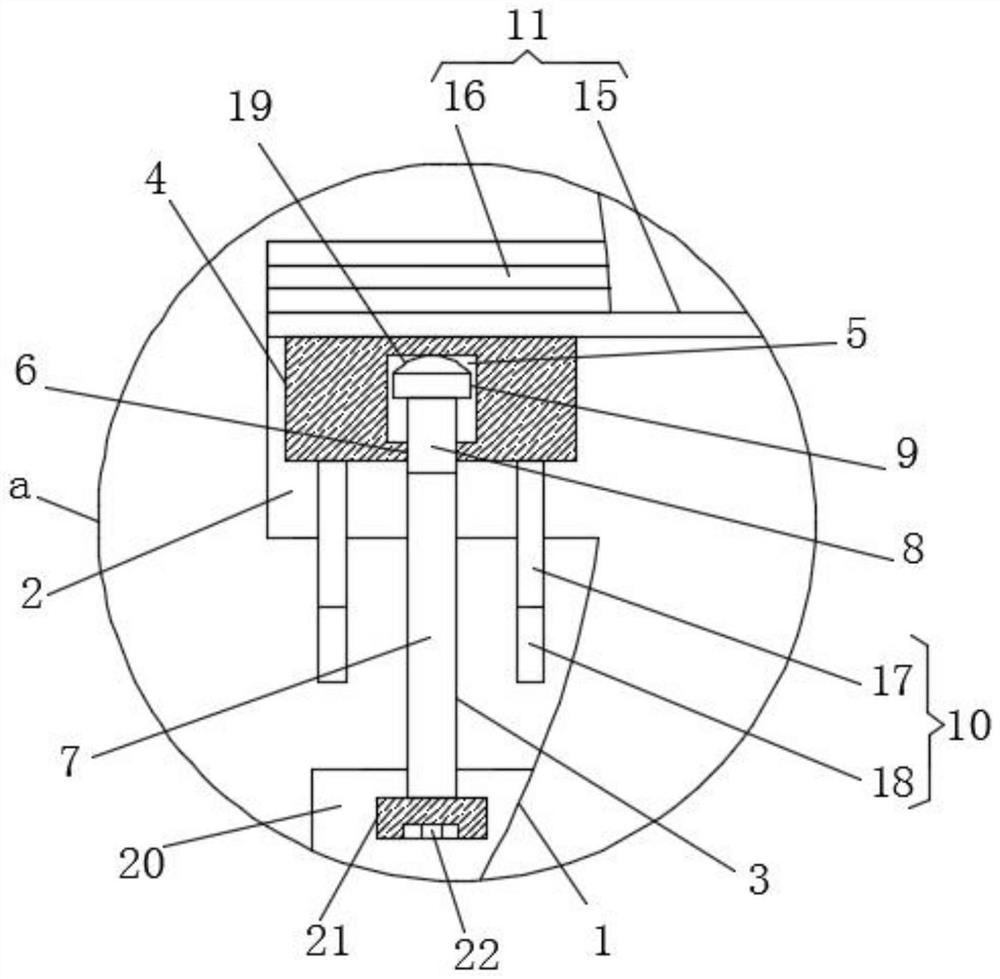

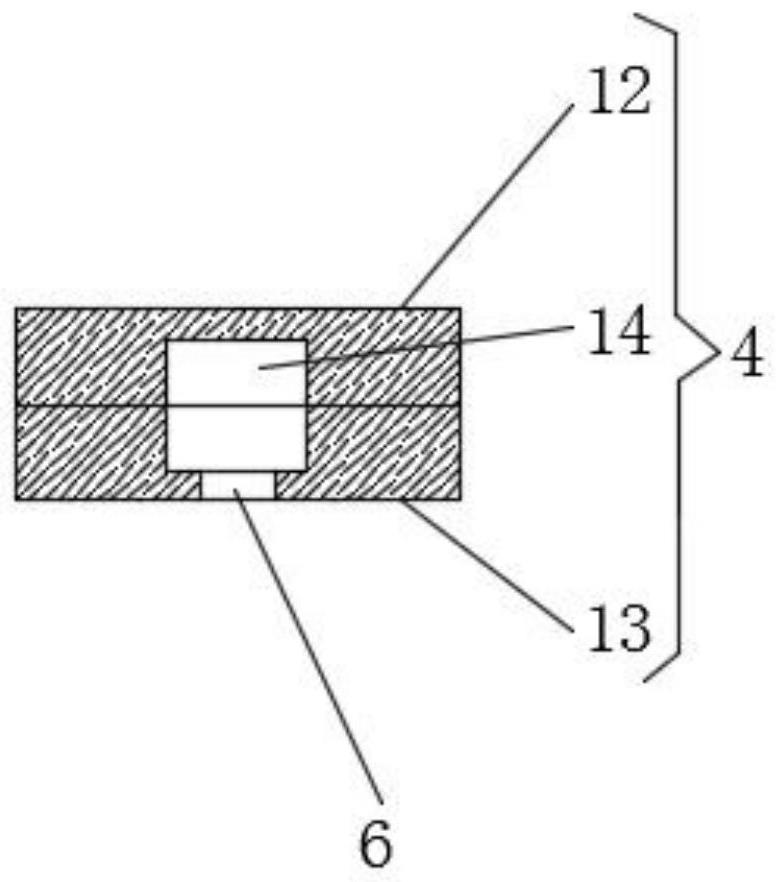

[0026] Such as Figure 1 to Figure 3 As shown, the rolling and fixing structure for non-woven paper described in this embodiment includes a winding shaft body 1, and the right end of the side wall of the winding shaft body 1 is provided with a strip groove 2, and the bottom of the strip groove 2 The front and rear ends of the wall are provided with screw holes 3, the top wall of the strip groove 2 is pasted with non-woven paper 11, the bottom of the non-woven paper 11 is pasted with a pressure plate 4, and both sides of the interior of the pressure plate 4 are provided with Cylindrical cavity 5, the bottom wall of cylindrical cavity 5 is provided with through hole 6, and the front and rear width of non-woven fabric paper 11 is less than the front and rear length of strip groove 2.

[0027] The screw hole 3 is screwed with a screw 7, the top of the screw 7 is welded with a vertical rod 8, and the top of the vertical rod 8 passes through the through hole 6 and is welded with a c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap