Hoisting equipment for fabricated building construction

A technology of building construction and hoisting equipment, which is applied in the direction of construction, building structure, and building material processing, etc. It can solve the problems of building damage, high work intensity, and easy swing of hanging ropes, etc., and achieve the effect of ensuring effective use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the embodiments, the purpose is only to better understand the content of the present invention, therefore, the examples do not limit the protection scope of the present invention.

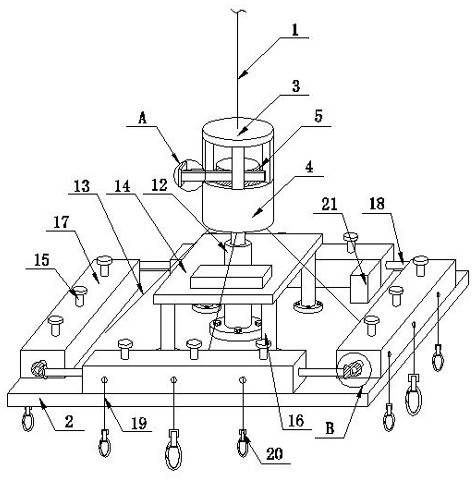

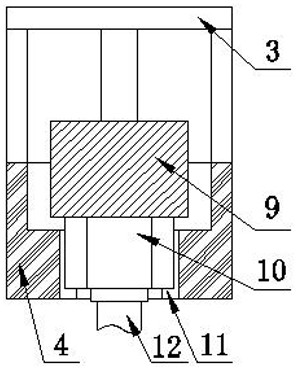

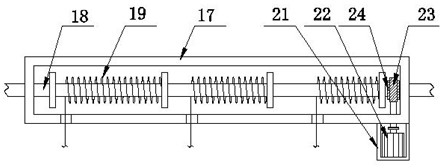

[0022] see Figure 1-Figure 5 , a prefabricated building construction hoisting equipment, including hoisting rope 1, hoisting plate 2, transfer cover 3, step bucket 4, step column 5, adjusting telescopic rod 6, push plate 7, tooth plate 8, gear column 9, Spline column 10, spline groove 11, lift telescopic rod 12, reinforcement rope 13, reinforcement plate 14, limit winding column 15, reinforcement column 16, storage box 17, linkage rod 18, pull rope 19, pull hook 20, expansion cover 21 , servo motor 22, worm 23, worm gear 24, bevel gear 25, the bottom of the hoisting rope 1 is provided with a transfer cover 3, the bottom of the transfer cover 3 is connected with the ladder bucket 4 through connecting rods, and the ladd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com