Mechanical training method for Ti-Ni marmem

A technology of memory alloy and training method, which is applied in the field of shape memory alloy, can solve the problems of phase transition temperature instability, material damage, and high cost, and achieve the effects of shortening training time, reducing training cost, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

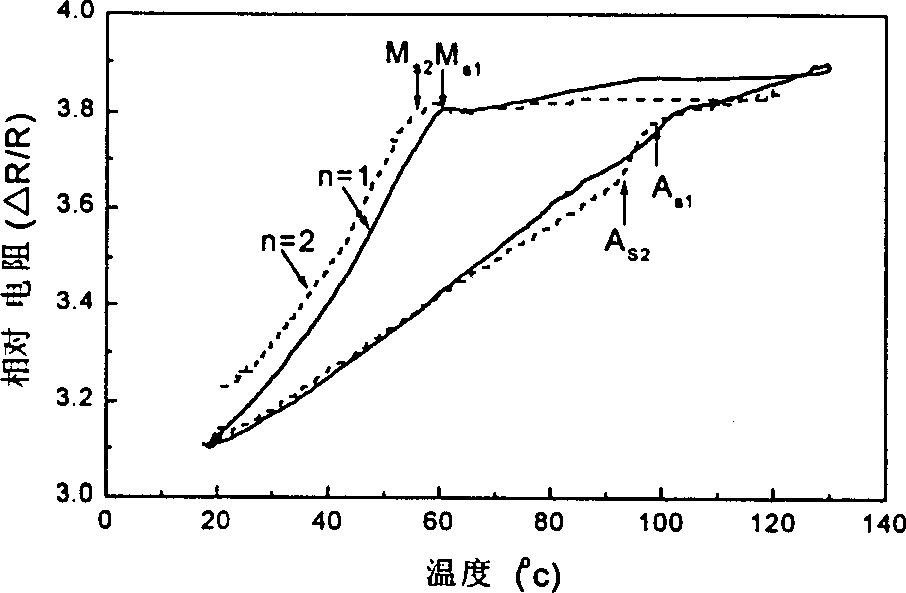

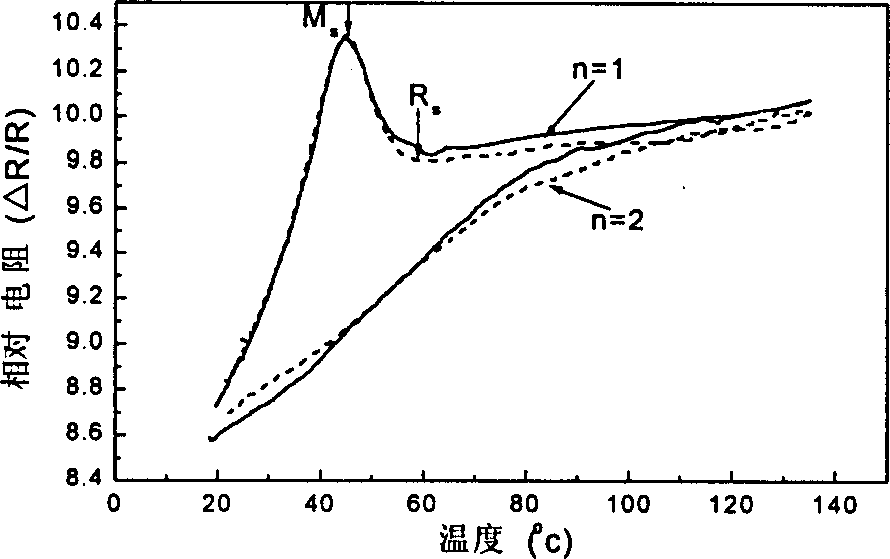

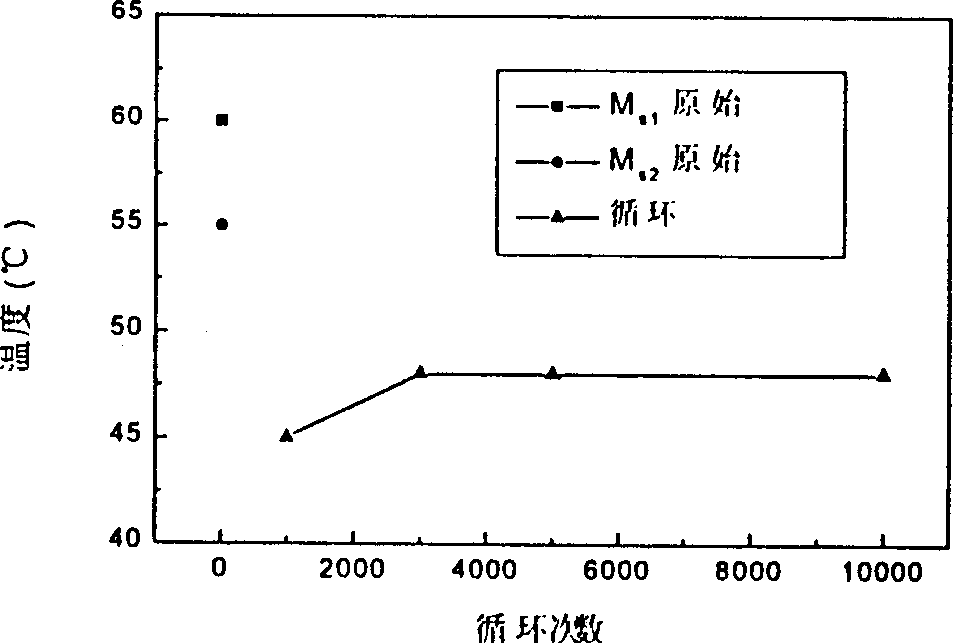

[0020] Taking Ti-49.6Ni shape memory alloy as an example, the material is vacuum induction smelted into an ingot of Ti-49.6% Ni alloy with an ingot weight of 10kg; after diffusion (homogenization) annealing at 900°C for 3 hours, hot rolling A rod with a diameter of 11 mm is processed at 750°C for 30 minutes, aged at 400°C for 1 hour, and cooled to room temperature in air. The material is in the martensite phase at room temperature, and its tensile yield strength at room temperature is 187 MPa. figure 1 Shown is the relative resistance-temperature curve of the material after solid solution and aging treatment. It can be seen from the figure that the martensitic transformation temperature measured twice in a row is unstable; the plastic strain amplitude is controlled, and the room temperature is loaded symmetrically in tension and compression. Plastic strain amplitude Δε p =5×10 -4 , the load ratio λ=-1, the waveform is a triangular wave, the frequency is 0.5Hz, and the plastic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com