Bogie and railway vehicle

A rail vehicle and bogie technology, applied in the field of rail vehicles, can solve problems affecting the running stability and riding comfort of rail vehicles, and achieve the effect of improving running stability and riding comfort, and avoiding steering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to make the technical problems, technical solutions and beneficial effects solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

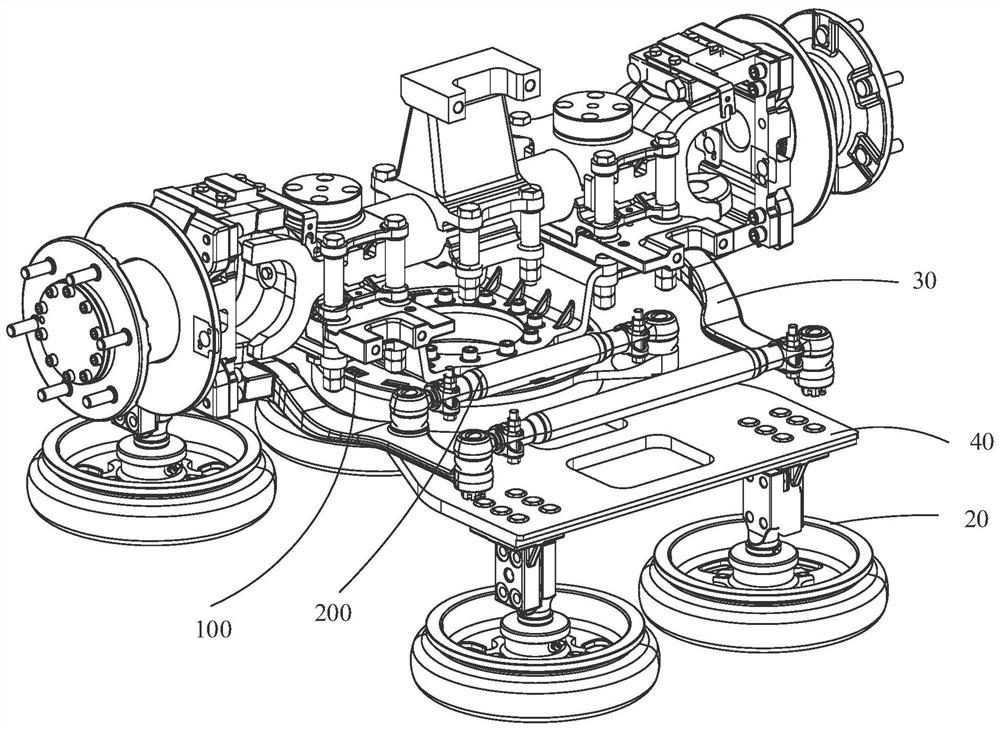

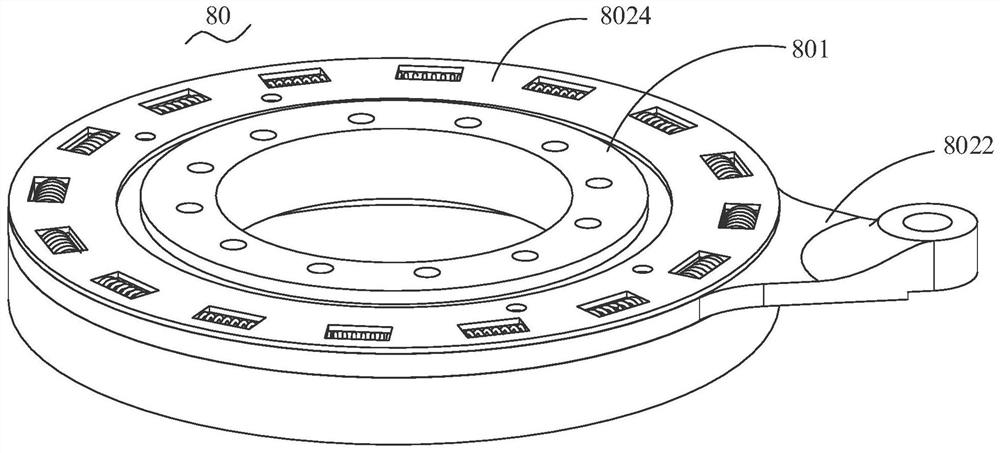

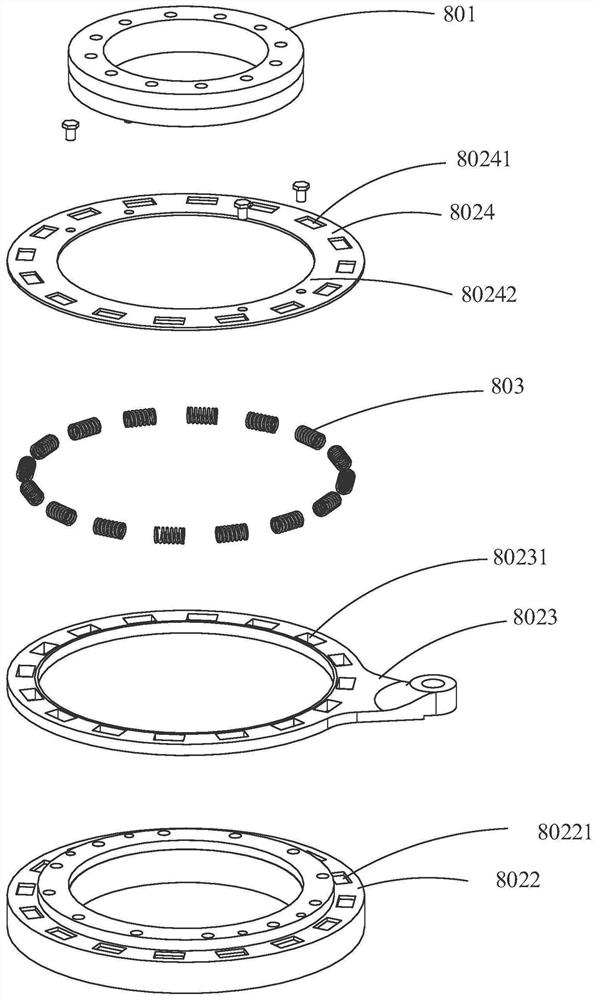

[0048] Such as Figure 1 to Figure 14 As shown, the embodiment of the present invention provides a bogie for a rail vehicle, including a traveling wheel 10, a guide frame 40, a multi-link mechanism 30, a slewing bearing 80 and a first elastic member 100, a multi-link mechanism and a traveling wheel 10 connections. The slewing support 80 includes a fixed part and a rotating part, the fixed part is connected with the vehicle body, the steering part can rotate relative to the fixed part, the rotating part includes a driving part 8022 and a driven part 8023, the driving part 8022 is connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com