Steel pipe plugging device

A plugging device and steel pipe technology, which is applied in the field of pipe bending, can solve the problems of insufficient sand filling in the pipe, sand leakage, deformation of the steel pipe, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

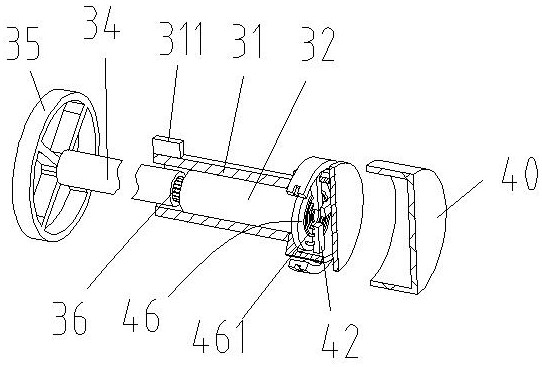

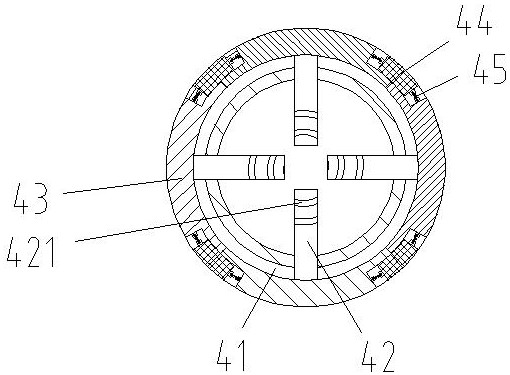

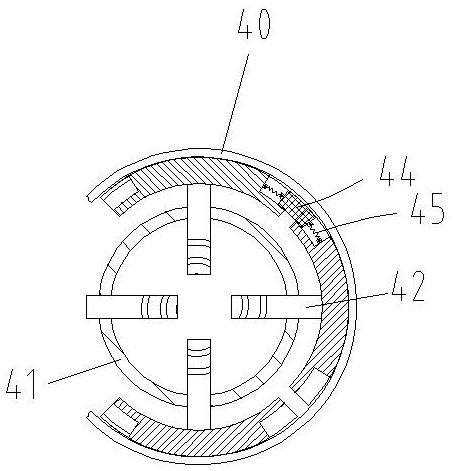

[0020] like Figure 1-3 As shown, a steel pipe plugging device of the present invention includes a base pipe 31 and an elastic sleeve 40, the elastic sleeve 40 is made of rubber, a positioning plate 311 is provided on the outside of the base pipe 31, and one end of the base pipe 31 is fixedly connected to the center pipe 41 , the tube wall of the central tube 41 is provided with an opening, and each opening is slidably connected with an adjustment column 42, and one end of the adjustment column 42 is fixedly connected with an arc-shaped adjustment block 43, and the adjustment block 43 is arranged in the elastic sleeve 40, each Both ends of the adjustment block 43 are provided with trapezoidal grooves, and a supplementary block 44 is arranged between the trapezoidal grooves of two adjacent adjustment blocks 43, and the two ends of the supplementary block 44 are respectively fixed in the trapezoidal grooves of the adjustment block 43 by extension springs 45. Rotate and connect t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com