Pressure compensation bulldozing hydraulic system of excavator

A pressure compensation and hydraulic system technology, which is applied to mechanically driven excavators/dredgers, fluid pressure actuators, mechanical equipment, etc., can solve the problems of not being able to satisfy the whole vehicle and not falling, and achieve pressure shock reduction, Avoid high-pressure oil circuit, good locking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

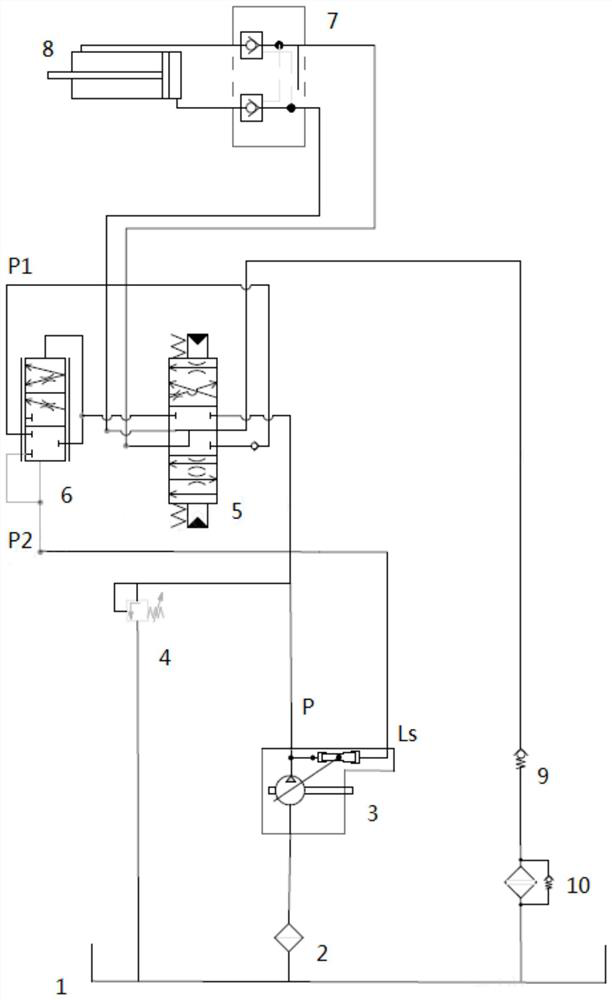

[0023] Such as figure 1 As shown, an excavator pressure compensation bulldozer hydraulic system is disclosed, comprising:

[0024] Variable displacement pump 3, the input end of the variable displacement pump 3 is externally connected to the hydraulic oil tank 1, the output end is connected to the main valve 5, and the output end of the main valve 5 is connected to the pressure compensation valve 6;

[0025] One of the oil passages of the pressure compensation valve 6 is connected to the two-way hydraulic lock 7 through the input end of the main valve 5, and the other oil passage is connected to the LS end of the variable pump 3, and the pressure compensation valve 6 makes the pressures of the two oil pressures equal; The oil return end of the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com